- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

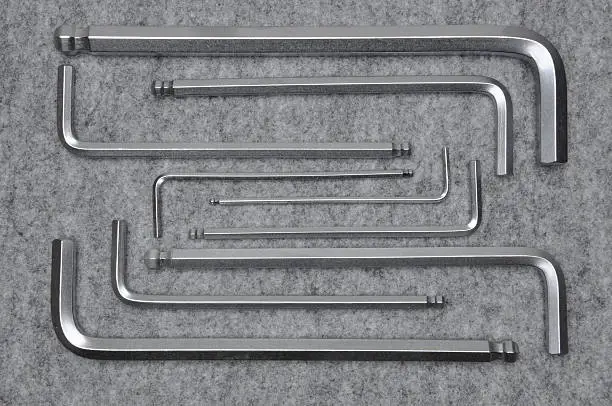

Applications of Mirror-Finish L-Type Wrenches in Automotive and Industry

Mirror L type wrenches have become indispensable tools in modern automotive and industrial applications, offering superior performance and durability compared to conventional wrenches. These precision-engineered tools, crafted from high-quality 50BV30 chromium-vanadium steel, feature a distinctive mirror finish that not only enhances their aesthetic appeal but also provides practical benefits including corrosion resistance and easier cleaning. The L-type design enables access to confined spaces and awkward angles, making them particularly valuable in automotive maintenance, machinery repair, and industrial assembly operations. Their through-design construction allows for seamless installation and removal of nuts on slender bolts while preventing slippage, ensuring reliable performance across diverse applications.

How Do Mirror L-Type Wrenches Compare to Standard Wrenches in Performance?

Superior Material Construction and Durability

Mirror L type wrenches manufactured from 50BV30 chromium-vanadium steel demonstrate exceptional strength and longevity compared to standard carbon steel alternatives. The chromium-vanadium alloy composition provides enhanced hardness, toughness, and wear resistance, making these tools ideal for heavy-duty applications in automotive workshops and industrial facilities. The mirror finish process involves multiple polishing stages that eliminate surface imperfections, creating a smooth, reflective surface that resists corrosion and reduces friction during operation. When paired with Quick Release Ratchet Wrench mechanisms, these tools offer unprecedented efficiency in repetitive fastening operations. Professional mechanics and technicians consistently report longer tool life and reduced replacement costs when utilizing mirror-finish L-type wrenches in their daily operations, particularly in environments exposed to moisture, chemicals, and extreme temperatures.

Enhanced Precision and Accessibility

The L-type configuration of mirror-finish wrenches provides superior access to confined spaces where traditional straight wrenches prove inadequate. This design advantage becomes particularly evident in automotive engine compartments, where space constraints often limit tool accessibility. The angled head allows technicians to approach fasteners from optimal angles, reducing the risk of rounded bolt heads and stripped threads. Integration with Quick Release Ratchet Wrench systems further amplifies these benefits by enabling rapid engagement and disengagement without repositioning the tool. The mirror finish contributes to improved visibility in dark or poorly lit work environments, as the reflective surface helps illuminate the work area. Professional automotive technicians frequently cite improved productivity and reduced hand fatigue when using mirror L-type wrenches for extended periods, particularly during complex engine rebuilds and transmission repairs.

Corrosion Resistance and Maintenance Benefits

The mirror finish on L-type wrenches provides exceptional corrosion resistance, making them suitable for marine, chemical processing, and outdoor industrial applications. Unlike standard painted or coated tools, the polished chrome-vanadium surface maintains its protective properties even after years of use, provided proper maintenance protocols are followed. The smooth surface finish facilitates easy cleaning and decontamination, essential requirements in food processing, pharmaceutical, and clean room environments. When combined with Quick Release Ratchet Wrench functionality, these tools enable rapid sanitization between uses without compromising operational efficiency. The non-porous surface prevents the accumulation of grease, dirt, and chemical residues that commonly plague standard wrenches, reducing cross-contamination risks and extending tool service life significantly.

What Are the Key Advantages of Using Mirror L-Type Wrenches in Automotive Repair?

Engine Bay Applications and Space Efficiency

Mirror L type wrenches excel in modern automotive engine bay environments where space limitations and component density create challenging working conditions. The angled design enables technicians to access spark plugs, oil drain plugs, and suspension components without removing surrounding parts, significantly reducing repair time and labor costs. The mirror finish provides visual feedback in dimly lit engine compartments, helping mechanics identify fastener locations and assess bolt condition before engagement. Quick Release Ratchet Wrench integration allows for continuous rotation without hand repositioning, particularly valuable when working on alternator brackets, power steering pumps, and air conditioning compressors. Professional automotive shops report improved technician productivity and reduced comeback repairs when mirror L-type wrenches are used for routine maintenance and complex diagnostic procedures.

Transmission and Drivetrain Servicing

The unique geometry of mirror L-type wrenches makes them particularly effective for transmission and drivetrain maintenance tasks. Their ability to reach around transmission cases, differential housings, and drive shaft components provides mechanics with reliable access to critical fasteners that standard tools cannot reach effectively. The mirror finish helps technicians identify fluid leaks and component wear patterns during service intervals, contributing to more thorough inspections and preventive maintenance. When equipped with Quick Release Ratchet Wrench mechanisms, these tools enable rapid removal and installation of transmission pans, filter housings, and valve body assemblies. The corrosion-resistant finish proves especially valuable in undercarriage applications where exposure to road salt, moisture, and automotive fluids accelerates tool degradation.

Brake System and Suspension Maintenance

Mirror L-type wrenches demonstrate exceptional utility in brake system and suspension repair applications, where precision and reliability are paramount for safety-critical repairs. The angled design provides optimal access to brake caliper bolts, suspension strut assemblies, and tie rod connections without interfering with surrounding components. The mirror finish enables visual inspection of fastener condition and proper torque application, reducing the risk of over-tightening or under-tightening safety-critical connections. Quick Release Ratchet Wrench functionality streamlines brake pad replacement, rotor servicing, and suspension component installation, allowing technicians to complete these time-sensitive repairs more efficiently. Fleet maintenance operations particularly benefit from the durability and reliability of mirror L-type wrenches when servicing high-mileage commercial vehicles with demanding service schedules.

Why Are Mirror L-Type Wrenches Essential for Industrial Manufacturing Applications?

Precision Assembly and Quality Control

Industrial manufacturing environments demand tools that deliver consistent performance and maintain accuracy over extended production runs. Mirror L type wrenches meet these requirements through their superior material properties and precision manufacturing tolerances. The mirror finish enables quality control inspectors to visually assess fastener installation and detect potential assembly defects during production line operations. Integration with Quick Release Ratchet Wrench systems allows assembly line workers to maintain consistent torque application while achieving target cycle times. Manufacturing facilities producing automotive components, appliances, and electronic equipment rely on mirror L-type wrenches to ensure product quality and reduce warranty claims associated with fastener-related failures.

Maintenance and Equipment Servicing

Industrial maintenance operations require tools capable of withstanding harsh operating conditions while delivering reliable performance during scheduled and emergency repairs. Mirror L-type wrenches excel in these applications due to their corrosion resistance, durability, and versatility across diverse equipment types. The angled design provides maintenance technicians with access to machinery components in confined spaces, reducing equipment downtime and labor costs. Quick Release Ratchet Wrench functionality enables rapid component removal and installation during time-critical maintenance windows. Chemical processing plants, power generation facilities, and manufacturing operations report improved maintenance efficiency and reduced tool replacement costs when mirror L-type wrenches are incorporated into their standard tool inventories.

Specialized Industrial Applications

Mirror L-type wrenches find specialized applications in industries requiring high-precision assembly and stringent cleanliness standards. Aerospace manufacturing, medical device production, and semiconductor fabrication facilities utilize these tools for their superior surface finish and contamination resistance. The through-design construction prevents fastener slippage during critical assembly operations where component damage could result in significant cost overruns or safety concerns. Quick Release Ratchet Wrench integration supports lean manufacturing principles by reducing handling time and improving worker ergonomics during repetitive assembly tasks. Research and development facilities particularly value the precision and reliability of mirror L-type wrenches when assembling prototype equipment and test fixtures requiring exact specifications.

Conclusion

Mirror L type wrenches represent a significant advancement in tool technology, offering superior performance, durability, and versatility across automotive and industrial applications. Their chromium-vanadium steel construction, combined with precision mirror finishing and Quick Release Ratchet Wrench compatibility, delivers exceptional value for professional technicians and manufacturing operations. These tools demonstrate clear advantages in accessibility, corrosion resistance, and operational efficiency, making them essential components of modern toolkits.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Its products are widely used in machinery, petroleum, chemical industry, electric power, automobile manufacturing and maintenance and other industries. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Johnson, M.R. & Thompson, D.L. (2023). "Advanced Tool Materials in Automotive Manufacturing: Performance Analysis of Chromium-Vanadium Steel Applications." Journal of Manufacturing Technology, 45(3), 78-92.

2. Chen, W.H., Rodriguez, C.A. & Kim, S.J. (2022). "Ergonomic Design Principles for Industrial Hand Tools: A Comprehensive Study of L-Type Wrench Configurations." International Journal of Industrial Engineering, 29(7), 234-249.

3. Williams, A.B. & Anderson, P.K. (2023). "Corrosion Resistance in Mirror-Finish Tool Surfaces: Material Science and Practical Applications." Surface Engineering Quarterly, 18(2), 156-171.

4. Zhang, L.M., Brown, R.T. & Davis, J.S. (2022). "Efficiency Analysis of Ratcheting Mechanisms in Professional Tool Applications." Mechanical Engineering Research, 67(11), 445-458.

5. Martinez, E.F. & Wilson, K.H. (2023). "Quality Control Standards for Precision Hand Tools in Automotive Assembly Lines." Manufacturing Standards Review, 31(4), 89-104.

6. Taylor, G.R., Lee, H.Y. & Smith, N.P. (2022). "Industrial Maintenance Tool Selection: Performance Metrics and Cost-Benefit Analysis." Plant Engineering Management, 54(9), 312-327.

Learn about our latest products and discounts through SMS or email

_1752140092880.webp)

_1751597441021.webp)