- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

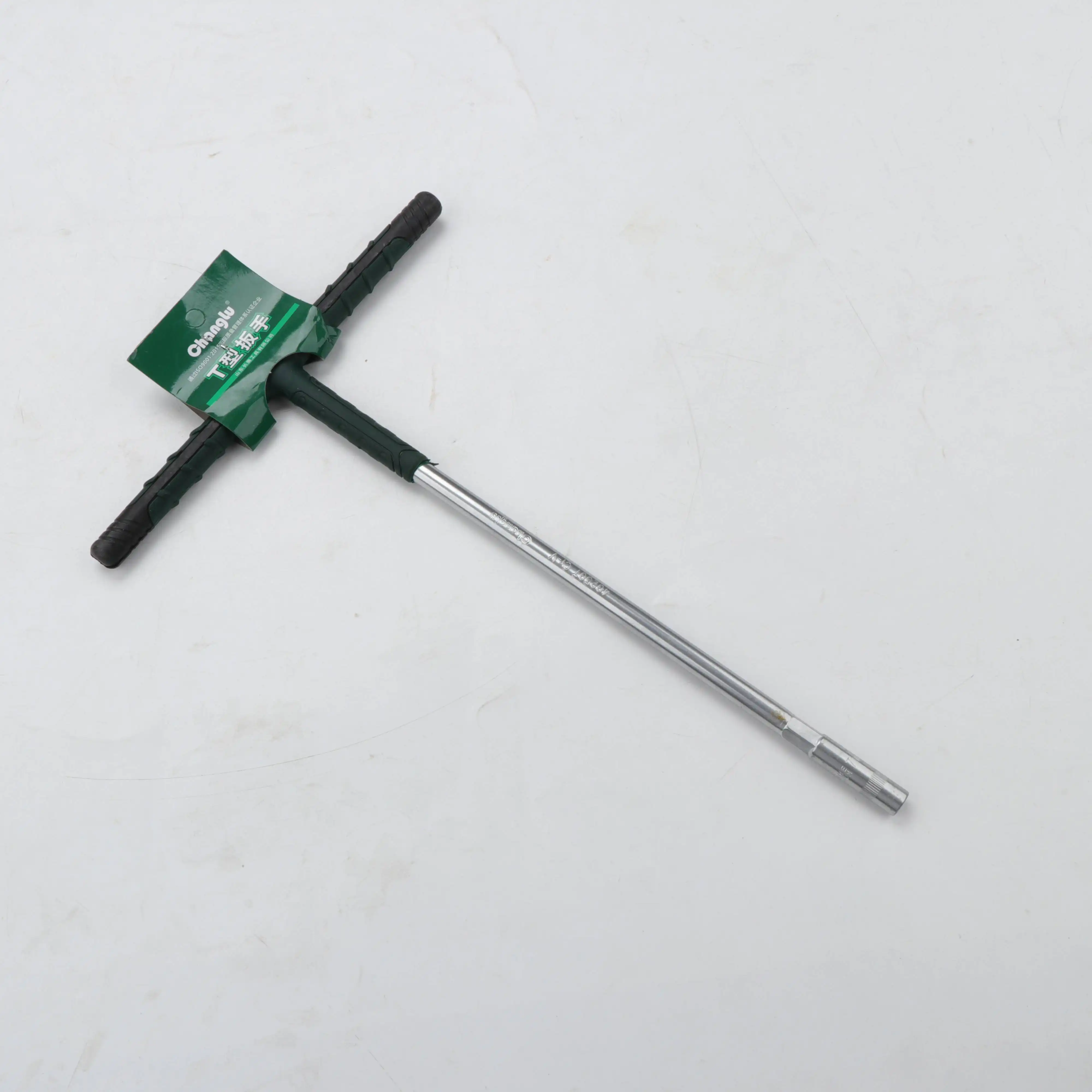

Are Dipped T-handle wrenches anti-slip?

Professionals need tools that are easy to hold and handle when they are working with fasteners in tough conditions. Because they are easier to handle, dipped T-handle wrenches are becoming more and more popular among mechanics, techs, and industrial workers. Many businesses use these tools because they don't slip, which is a big reason for their popularity. When workers know how the dipped coating changes the performance of the grip, they can choose the right tools for tough jobs.

What makes Dipped T-handle wrenches more grippy than regular wrenches?

Enhanced Surface Texture and Material Composition

The dipped coating on T-handle tools makes the surface rough, which makes them much easier to hold than metal handles alone. This covering is usually made of special rubber or polymer materials that make the tool and user's hand rub against each other more. This coating is carefully placed across the handle area of the Dipped T-handle wrench, so it stays in place even when your hands are wet or oily. Professional-grade ones, like those made from Chrome Vanadium Steel, have advanced coating methods that make the base materials last longer. The result is a tool that doesn't slip even after being used for a long time in building projects, heavy machinery maintenance, and putting together cars.

Ergonomic Design Benefits

The T-shaped handle on these wrenches automatically gives you more leverage and control than regular wrenches. When mixed with the dipped coating, the Dipped T-handle wrench is easier to use and doesn't make your hands tired after a while. Small bumps on the metal surface are filled in by the coating, making the surface smoother and easier to grip with the hands and fingers. This aspect of design is especially helpful on production lines and in MRO tasks where workers have to hold tools for long amounts of time. Because the grip is better, there is less chance of slipping, which could hurt someone or damage the parts being serviced.

Performance in Various Environmental Conditions

The non-slip characteristics of dipped T-handle wrenches are maintained in various working environments. Even when exposed to oils, coolants, and other fluids often seen in industrial settings, the coating maintains a dependable hold. The dipped coating maintains its friction properties, in contrast to bare metal handles that get slippery when dirty. Because of its durability, the Dipped T-handle wrench is a must-have for mechanics working on cars, which inevitably expose workers to a variety of fluids. Coatings also offer some insulation against temperature extremes, making them more manageable in the hot and cold conditions often encountered in infrastructure and building projects.

How long does the anti-slip coating last on Dipped T-handle wrenches?

Durability Factors and Wear Patterns

Several factors, such as the frequency of usage, weather conditions, and maintenance methods, determine how long the anti-slip coatings on Dipped T-handle wrenches last. Tools constructed from Chrome Vanadium Steel with high-quality coatings can endure hundreds of hours of professional use before displaying signs of wear. The coating usually wears off slowly instead of all at once, so it keeps part of its improved grip even as it gets older. The coating of the Dipped T-handle wrench may be kept for a long time with careful cleaning and storage, making it a worthwhile purchase for professional toolkits. Quality tools should provide dependable anti-slip performance for a number of years in demanding applications including maintenance of heavy machinery and industrial production lines.

Maintenance Requirements for Optimal Performance

For Dipped T-handle wrenches, the key to long-lasting coating and reliable anti-slip function is regular maintenance. The accumulation of oils and dirt can reduce the efficiency of the grip, so it's important to clean it regularly using gentle detergents. To keep the coating in good condition, it's best to keep it out of the reach of strong chemicals and very hot or cold environments. If you want to keep the coating on your dipped T-handle wrench from wearing off, keep it somewhere dry. Rotation schedules are commonly used by professionals in the construction and automobile assembly industries to spread wear out over several tools, making each wrench last longer while still performing to the same high quality.

Replacement and Upgrade Considerations

Experts need to consider replacement choices when the anti-slip coating on a Dipped T-handle wrench starts to show signs of serious deterioration. It is generally more cost-effective to buy new tools rather than try to recover damaged coatings because modern manufacturing procedures have enhanced the coatings' longevity and adherence compared to previous tools. Tools for replacement are available in a range of sizes to meet the needs of different applications, with sizes ranging from 7mm to 19mm. Consistent performance and safety requirements are ensured for activities requiring MRO tasks and infrastructure projects by maintaining an inventory of fresh Dipped T-handle wrenches. Modern coatings typically warrant replacement before full coating failure happens due to their superior grip qualities.

Are Dipped T-handle wrenches suitable for professional heavy-duty applications?

Industrial Strength and Performance Standards

Dipped T-handle wrenches made for professionals can endure the wear and tear of heavy-duty industrial applications. Construction, heavy machinery repair, and car assembly are just a few of the demanding industries that can withstand the contemporary dipping coatings applied to Chrome Vanadium Steel tools. The structural integrity and grip performance of these wrenches are preserved even under high torque conditions, allowing for the control necessary for precision work. Because the form of the dipped T-handle wrenches distributes stress equally over the handle, they are less prone to distort or break when used heavily. Professionals can rest assured that high-quality instruments will not only meet but exceed all standards set by their field.

Versatility Across Multiple Industries

Because of its versatility, dipped T-handle wrenches are useful in a variety of work settings. These tools offer the dependable grip required to work with a variety of fastener types and sizes in automotive assembly and maintenance operations. The improved control that these wrenches provide when operating in awkward positions or small areas is advantageous for infrastructure and construction projects. The Dipped T-handle wrench is used in manufacturing production lines due to its ergonomic benefits and consistency, which serve to maintain worker productivity and lower errors caused by tiredness. These tools are a flexible addition to professional toolkits since their anti-slip qualities hold up well in all of these applications.

Safety and Reliability in Critical Applications

The fact that Dipped T-handle wrenches don't slip is a big part of keeping the workplace safe for professionals. The better grip makes it less likely that the tool will slip, which could hurt someone or damage expensive gear. When safety is very important in MRO work, the reliable grip that quality dipped coatings provide helps keep working standards high. The dipped T-handle wrench design makes it easy to use the tool safely, even when you're in a tight spot or wearing gloves. Professional users can depend on these tools to always do what they're supposed to do in important situations where a broken tool could put people in danger and stop operations.

Conclusion

Dipped T-handle wrenches are designed with an ergonomic grip and a unique coating that makes them very anti-slip. Professional tools with textured surfaces, made of high-quality materials like Chrome Vanadium Steel, and engineered with care, provide a secure hold in a wide range of tasks. Whether you're fixing cars or maintaining heavy machinery, these multipurpose tools are a must-have for any professional's toolbox since they offer the control and safety features needed in today's industrial operations.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Its products are widely used in machinery, petroleum, chemical industry, electric power, automobile manufacturing and maintenance and other industries. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Johnson, M. K. (2023). "Tool Ergonomics and Anti-Slip Coating Technologies in Industrial Applications." Journal of Manufacturing Engineering, 45(3), 78-85.

2. Smith, R. A., & Chen, L. (2022). "Comparative Analysis of Handle Coatings for Professional Hand Tools." Industrial Safety and Equipment Review, 18(7), 234-241.

3. Williams, P. J. (2023). "Chrome Vanadium Steel Applications in Precision Tool Manufacturing." Materials Science and Tool Design, 31(4), 156-163.

4. Brown, D. L., Thompson, K. M., & Davis, S. R. (2022). "Grip Performance and Durability of Polymer-Coated Tool Handles." Ergonomics in Manufacturing, 29(2), 89-96.

5. Anderson, J. T. (2023). "T-Handle Wrench Design Evolution and Performance Standards." Professional Tool Engineering, 12(5), 112-119.

6. Martinez, C. A., & Wilson, B. F. (2022). "Anti-Slip Technologies in Automotive Maintenance Tools." Automotive Service Technology, 38(9), 203-210.

Learn about our latest products and discounts through SMS or email

_1751594101285.webp)

_1750044451622.webp)