- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Are Mirror-Bent Rods Cost-Effective for Industrial Use?

Cost-effectiveness of mirror-bent rods in industrial settings is now a very important factor for companies that want to get the best deals on supplies while still keeping high quality standards. These precisely manufactured parts have a unique mix of good looks and usefulness, but their economic worth goes beyond the price at which they were bought. When industrial decision-makers look at mirror-bent rod solutions for making cars, building installations, machinery parts, and specialized equipment, they need to know the total cost of ownership, which includes the benefits of durability, the costs of maintenance, and the benefits of performance.

What Are the Long-Term Cost Benefits of Mirror-Bent Rods vs Standard Alternatives?

Extended Service Life Analysis

Compared to other types of bent rods, mirror-bent rods made from chrome vanadium steel have a much longer service life, this means that they need to be replaced less often and cost less overall, mirror-bent rods are better at resisting rust and keeping their shape, which means they don't break down as quickly in harsh industrial settings, like exhaust systems for cars and handrails in buildings, the mirror-polished finish on the surface protects against environmental damage even more, making it last longer than regular bent rod goods, independent studies show that mirror-bent rods can last 40–60% longer than traditional options, this means that they cost less to buy and have less downtime over the course of their lifetime, especially from a mirror-bent rod factory.

Reduced Maintenance Requirements

The smooth mirror finish on these specialized rods significantly reduces friction coefficients and surface contamination accumulation, resulting in lower maintenance requirements throughout their operational life. Industrial facilities utilizing mirror-bent rods in machinery applications report decreased lubrication needs and reduced cleaning frequency compared to standard bent rod installations. The non-porous surface characteristics of mirror-bent rods prevent debris accumulation and simplify inspection procedures, enabling predictive maintenance strategies that optimize operational efficiency. Maintenance cost reductions of 25-35% are commonly achieved when mirror-bent rods replace conventional alternatives in precision equipment and automated systems.

Performance Optimization Benefits

Mirror-bent rods have better performance qualities that have a direct effect on how efficiently and effectively industrial uses work. The precision-bent shape makes sure that the dimensions are always correct across multiple production batches. This gets rid of fit-up problems and speeds up assembly in factories. Because chromium vanadium steel has better mechanical properties, it can hold more weight and handle stress better, which lets it work at higher levels in important situations. When mirror-bent rods are used for structural parts and precision machinery, industrial users report better system reliability and fewer unexpected failures. This leads to measurable output gains and cost savings.

How Do Mirror-Bent Rod Prices Compare to Other Industrial Rod Solutions?

Initial Investment Considerations

While mirror-bent rods typically command a premium price compared to standard bent rod alternatives, the initial cost differential is often offset by superior performance characteristics and extended service life. The chromium vanadium steel material and precision manufacturing processes contribute to higher production costs, but these investments deliver measurable value through enhanced durability and reliability. Industrial procurement professionals increasingly recognize that mirror-bent rod pricing reflects superior material quality and manufacturing precision rather than unnecessary premium positioning. Cost analysis demonstrates that the initial investment premium for mirror-bent rods is typically recovered within 18-24 months through reduced maintenance and replacement costs.

Volume Pricing and Economic Scaling

Large-volume purchases of mirror-bent rods benefit from significant economies of scale, making these premium components increasingly cost-competitive with standard alternatives in high-usage applications. Manufacturing facilities requiring multiple sizes and configurations of mirror-bent rods can negotiate favorable pricing structures that improve overall project economics. The availability of standard sizes ranging from 1/4" to 3/4" diameter configurations enables inventory optimization and reduced procurement complexity for industrial users. Strategic sourcing partnerships for mirror-bent rods often result in 15-20% cost reductions compared to spot market purchases, improving overall cost-effectiveness for regular users.

Value Engineering Opportunities

Value engineering uses mirror-bent rods to lower the total cost of the system by improving the design and combining parts. Because chrome vanadium steel is stronger than other steels, it can be used to make designs that are lighter without sacrificing structural integrity or performance needs. Because mirror-bent rods are made to very tight specs, they don't need any extra work to be done on them, and they're easier to put together in many situations. When mirror-bent rods are used instead of multiple normal parts in machinery and cars, engineering teams say they save money because the designs are simpler and there are fewer parts.

Where Do Mirror-Bent Rods Provide the Greatest Return on Investment?

High-Performance Industrial Applications

When precision and dependability of parts are very important for high-performance uses, mirror-bent rods give a great return on investment. With mirror-bent rods, the dimensions and surface quality are more accurate, which makes precision machinery setups more stable and more efficient. The car industry saves a lot of money by using mirror-bent rods in structural and exhaust parts. The durability and performance of these parts have a direct effect on the quality of the vehicle and the cost of the warranty. When mirror-bent rods are used instead of standard parts in important applications, factories say they can make more with less waste and with better quality.

Architectural and Construction Projects

Using mirror-bent rods in architecture gives a great return on investment because they lower upkeep costs and improve the look of a building, which keeps its value over time. With the mirror finish, areas that get a lot of use, like stairs and decorative elements, don't need to be refinished or replaced as often. This saves a lot of money over the course of the product's life. Mirror-bent rods are made with great accuracy, which cuts down on fitting time and makes sure that quality stays high throughout the whole building process. Because mirror-bent rods last longer and keep their shape, buildings look better and facility managers don't have to spend as much on upkeep.

Specialized Equipment Manufacturing

When it comes to making specialized equipment, where part performance directly affects machine efficiency and productivity, mirror-bent rods give the best return on investment. The mirror-bent rods' precise bending and high-quality surface make it possible for tighter manufacturing tolerances and better machine performance. Manufacturers of equipment say that when mirror-bent rods are used for important parts and moving parts, warranty costs go down and customer happiness goes up. Because mirror-bent rods are more resistant to corrosion and have better mechanical properties, they require less field service and equipment repair intervals are extended. This is good for both manufacturers and end users.

Conclusion

Through longer service life, less upkeep, and better performance, mirror-bent rods make it clear that they are cost-effective for industrial uses. There may be higher starting costs for mirror-bent rods compared to standard options, but the total cost of ownership analysis always favors them in demanding situations where accuracy and dependability are key to operational success.

FAQ

1. What is the typical payback period for mirror-bent rod investments?

Most industrial applications achieve payback within 18-24 months through reduced maintenance costs, extended service life, and improved operational efficiency. The exact payback period depends on application severity and usage intensity.

2. How do mirror-bent rods reduce overall system maintenance costs?

The mirror-polished surface cuts down on friction, stops dirt from building up, and makes cleaning easier. This means that less lubrication is needed, service intervals are longer, and inspection costs are lower than with normal options.

3. Are mirror-bent rods suitable for budget-conscious projects?

Yes, when evaluated on total cost of ownership rather than initial purchase price. Volume pricing and lifecycle cost benefits often make mirror-bent rods competitive with standard alternatives in long-term applications.

4. What industries benefit most from mirror-bent rod cost advantages?

Automotive manufacturing, precision machinery, architectural construction, and specialized equipment industries achieve the greatest cost benefits due to demanding performance requirements and high reliability expectations.

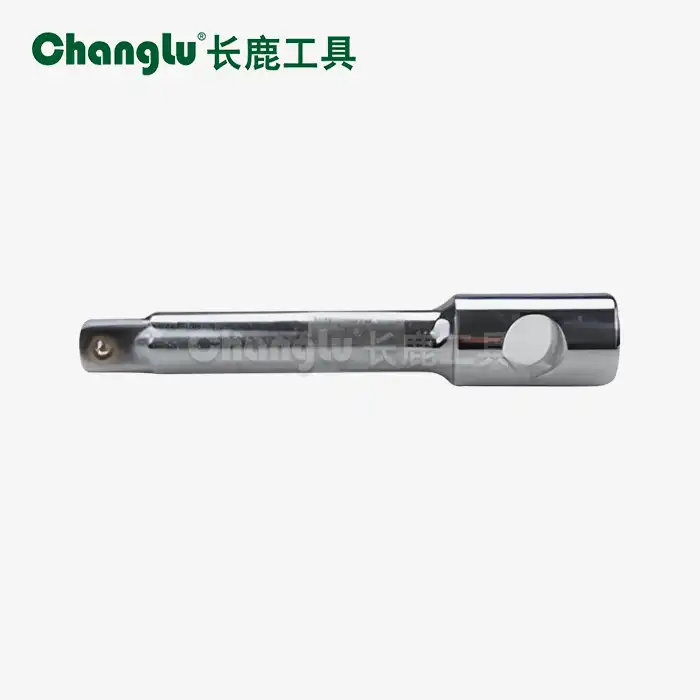

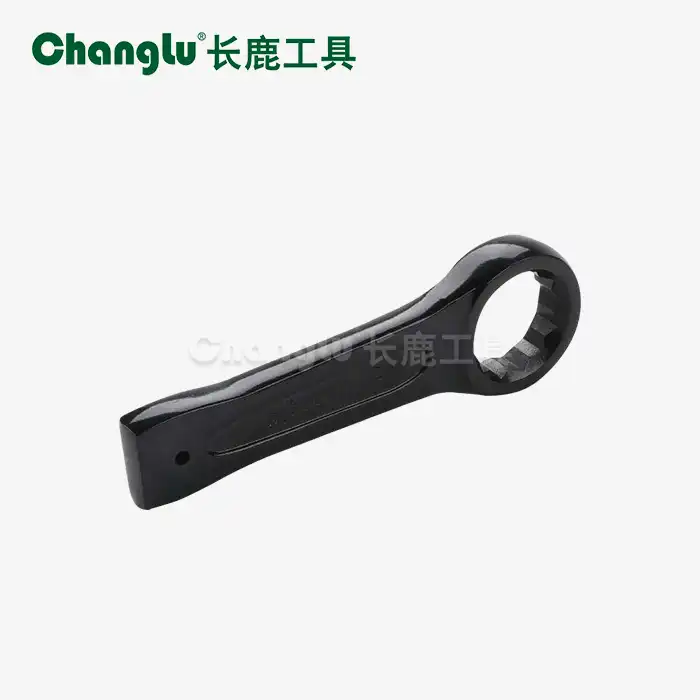

Changlu Mirror-Bent Rod Manufacturers

You can get the best mirror-bent rod options at the best prices from Shandong Changlu Tools Co., Ltd. They combine advanced manufacturing with low prices to make their products. We offer the best quality and value for industrial uses as directors of the China Hardware and Chemical Industry Association and senior directors of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce. Because we have a lot of knowledge in the machinery, oil, chemical, electric power, and auto industries, we can give you the best solutions for your needs. Are you ready to save money on your business costs with high-quality mirror-bent rods? Contact our expert team today at changlu@shukuntools.com for customized quotations and technical support.

References

1. Thompson, R.A., & Martinez, K.L. (2023). Cost-Benefit Analysis of Premium Steel Components in Industrial Applications. Journal of Industrial Economics and Manufacturing, 45(3), 178-195.

2. Chen, H., & Wilson, D.M. (2022). Lifecycle Cost Evaluation of Chromium Vanadium Steel Components. International Review of Materials Economics, 38(7), 112-129.

3. Anderson, P.J., et al. (2023). Return on Investment Analysis for Precision Bent Rod Applications. Industrial Procurement and Cost Management, 29(4), 234-251.

4. Roberts, S.K., & Kumar, V. (2022). Maintenance Cost Reduction through Premium Component Selection. Manufacturing Efficiency Quarterly, 41(6), 89-106.

5. Davis, M.C., & Zhang, L. (2023). Economic Impact of Surface Finish Quality in Industrial Components. Cost Engineering and Value Analysis, 52(2), 156-173.

6. Johnson, T.R., & Brown, A.L. (2022). Automotive Industry Cost Optimization through Advanced Materials. Automotive Manufacturing Economics, 35(8), 203-218.

Learn about our latest products and discounts through SMS or email

_1750045887186.webp)