- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Best applications for a professional grade adjustable torque wrench?

Professional grade Adjustable torque wrench serve as irreplaceable instruments over various businesses where exact latch fixing decides operational security, basic keenness, and execution unwavering quality. These flexible disobedient exceed expectations in applications extending from fragile aviation component get together to heavy-duty mechanical apparatus support, advertising the adaptability to handle different torque necessities inside a single apparatus stage. Understanding ideal applications makes a difference experts maximize their venture whereas guaranteeing compliance with industry benchmarks and security directions. Present day movable torque torques give remarkable flexibility through wide torque ranges, ±4% precision details, and solid chromium-vanadium steel development that withstands requesting operational situations over numerous sectors.

Which automotive applications benefit most from professional grade adjustable torque wrenches?

Engine Assembly and Maintenance

The proficient review flexible torque torque demonstrates basic for motor get together assignments where exact torque details guarantee ideal execution and life span. Basic applications incorporate barrel head jolt establishment, where disgraceful torque can lead to gasket disappointment, coolant spills, or disastrous motor harm. The movable extend capability of the proficient review movable torque torque suits different latch sizes inside motor compartments, from fragile sensor mounting jolts requiring 5-25 N.m torque to primary bearing caps requesting 200-1000 N.m determinations. Proficient mechanics depend on the ±4% exactness of the proficient review movable torque torque to accomplish producer details that optimize motor compression, avoid component push, and guarantee guarantee compliance over different vehicle models and motor configurations.

Wheel and Brake System Installation

Automotive wheel installation represents a critical safety application where the pro-grade torque wrench prevents both under-torquing that could cause wheel separation and over-torquing that damages wheel studs or brake rotors. Modern vehicles require precise lug nut torque specifications that vary significantly between vehicle types, from compact cars requiring 60-300 N.m to heavy trucks demanding higher torque values. The pro-grade torque wrench accommodates this range diversity while ensuring consistent torque application across all wheel positions. Brake caliper mounting, disc rotor installation, and suspension component assembly also benefit from the precision offered by the pro-grade torque wrench, where accurate torque application directly impacts vehicle safety and handling performance.

Transmission and Drivetrain Components

Complex transmission assemblies require the precision offered by a professional grade adjustable torque wrench to ensure proper component alignment and seal integrity throughout the drivetrain system. Transmission case bolts, differential housing fasteners, and CV joint components each require specific torque values that fall within the adjustable range of professional grade tools. The chromium-vanadium steel construction of the professional grade adjustable torque wrench provides the durability needed for repeated use in automotive service environments where contamination and harsh conditions are common. Professional automotive technicians appreciate how the ergonomic design of the professional grade adjustable torque wrench reduces fatigue during extensive transmission rebuilds and drivetrain maintenance procedures that require numerous torque applications.

How do industrial manufacturing processes utilize professional grade adjustable torque wrenches?

Assembly Line Operations

Manufacturing assembly lines demand consistent, repeatable torque application that the professional grade adjustable torque wrench delivers through its precise calibration and durability. Production environments benefit from the tool's ability to maintain accuracy across thousands of operation cycles, ensuring product quality and reducing warranty claims related to fastener failure. The professional grade adjustable torque wrench accommodates diverse product lines within single facilities, eliminating the need for multiple specialized tools while maintaining the precision required for quality management systems. ISO 6789 certification of the professional grade adjustable torque wrench provides traceability required by manufacturing quality standards, enabling documentation of torque application for regulatory compliance and process validation in industries ranging from electronics to heavy machinery production.

Heavy Machinery Maintenance

Industrial machinery maintenance requires the robust construction and wide torque range offered by the industrial grade torque tool to service equipment ranging from precision manufacturing tools to massive production machinery. Critical applications include bearing housing assembly, coupling installation, and structural frame fastening where precise torque prevents equipment failure and production downtime. The industrial grade torque tool handles maintenance tasks on conveyor systems, hydraulic equipment, and processing machinery where torque specifications vary dramatically within single maintenance procedures. Maintenance teams appreciate the versatility of the industrial grade torque tool, which reduces tool inventory requirements while ensuring compliance with manufacturer specifications and safety regulations governing industrial equipment operation.

Quality Control and Inspection

Quality control departments utilize the professional grade adjustable torque wrench for verification testing of assembled products, ensuring that fastener torque meets design specifications before products leave manufacturing facilities. This application requires the exceptional accuracy and calibration stability offered by professional grade tools to provide reliable measurement data for quality documentation systems. The professional grade adjustable torque wrench serves audit functions where independent torque verification confirms assembly process compliance and identifies potential issues before they result in field failures. Manufacturing facilities rely on the documented accuracy of the professional grade adjustable torque wrench to satisfy customer quality requirements and regulatory inspections that demand traceable torque measurement capabilities across diverse product lines and assembly processes.

What aerospace and energy sector applications require professional grade adjustable torque wrenches?

Aircraft Component Assembly

Aerospace applications represent the most demanding environment for the professional grade adjustable torque wrench, where precise torque application directly impacts flight safety and structural integrity. Critical fasteners in aircraft structures, engine mounts, and control surfaces require torque specifications that must be achieved within extremely tight tolerances to prevent catastrophic failure. The professional grade adjustable torque wrench meets aerospace quality standards through its ISO 6789 certification and documented accuracy performance that satisfies regulatory requirements for commercial and military aircraft maintenance. Aerospace technicians rely on the tool's consistent performance across temperature variations and the durability needed for field maintenance operations where equipment reliability directly impacts mission success and personnel safety.

Wind Turbine Installation and Maintenance

The energy sector utilizes the premium quality torque wrench extensively in wind turbine installation and maintenance operations where large structural fasteners require precise torque application to withstand extreme environmental conditions. Tower assembly, nacelle installation, and blade mounting operations depend on the high torque range capabilities of the premium quality torque wrench to achieve specifications often exceeding 1000 N.m. Field maintenance teams working at significant heights appreciate the ergonomic design and reliability of the premium quality torque wrench, which reduces the need for multiple tools while ensuring consistent torque application in challenging weather conditions. The tool's durability and accuracy retention make it ideal for renewable energy applications where equipment accessibility and maintenance intervals demand reliable tool performance.

Oil and Gas Infrastructure

Oil and gas operations require the professional grade adjustable torque wrench for pipeline installation, wellhead assembly, and refinery maintenance where fastener integrity directly impacts operational safety and environmental protection. High-pressure applications demand precise torque values to ensure seal integrity and prevent leakage that could result in environmental contamination or safety hazards. The professional grade adjustable torque wrench handles diverse applications from delicate instrumentation mounting to massive pipeline flange assembly within single projects. Chemical resistance and durability of the chromium-vanadium steel construction make the professional grade adjustable torque wrench suitable for harsh petrochemical environments where contamination and corrosive substances challenge tool performance and longevity.

Conclusion

Professional review movable torque torques exceed expectations over car, fabricating, aviation, and vitality applications where exactness torque control guarantees security, quality, and execution. Their flexibility, ±4% exactness, and solid development make them irreplaceable for applications extending from fragile component gathering to heavy-duty basic securing. The combination of wide torque ranges, ISO certification, and ergonomic plan gives experts with dependable instruments that improve efficiency whereas assembly exacting industry benchmarks and security requirements.

FAQ

1. What torque range should I choose for automotive applications?

For general automotive work, the professional grade adjustable torque wrench with 20-100 N.m or 40-200 N.m ranges covers most applications including engine components, suspension parts, and wheel installations. Heavy-duty automotive applications may require 200-1000 N.m ranges for truck components and large fasteners. Consider your specific vehicle types and most common applications when selecting range specifications.

2. How does ISO 6789 certification benefit industrial applications?

ISO 6789 certification ensures the professional grade adjustable torque wrench meets international accuracy standards required for quality management systems and regulatory compliance. This certification provides traceability documentation needed for manufacturing quality control, audit requirements, and customer specifications. Industrial applications benefit from the consistency and reliability that certified tools provide.

3. Can one adjustable torque wrench handle multiple industry applications?

Yes, the professional grade adjustable torque wrench with appropriate torque ranges can serve multiple industries effectively. The wide adjustment capability and durable construction make it suitable for diverse applications from delicate electronics assembly to heavy industrial maintenance. However, specialized applications may require dedicated tools optimized for specific industry requirements.

4. What maintenance is required for professional grade adjustable torque wrenches?

Regular calibration according to manufacturer specifications maintains accuracy, typically annually or after specified usage cycles. Proper storage with torque settings released to minimum, regular cleaning, and appropriate lubrication extend tool life. Following manufacturer maintenance guidelines ensures continued accuracy and reliability throughout the tool's service life.

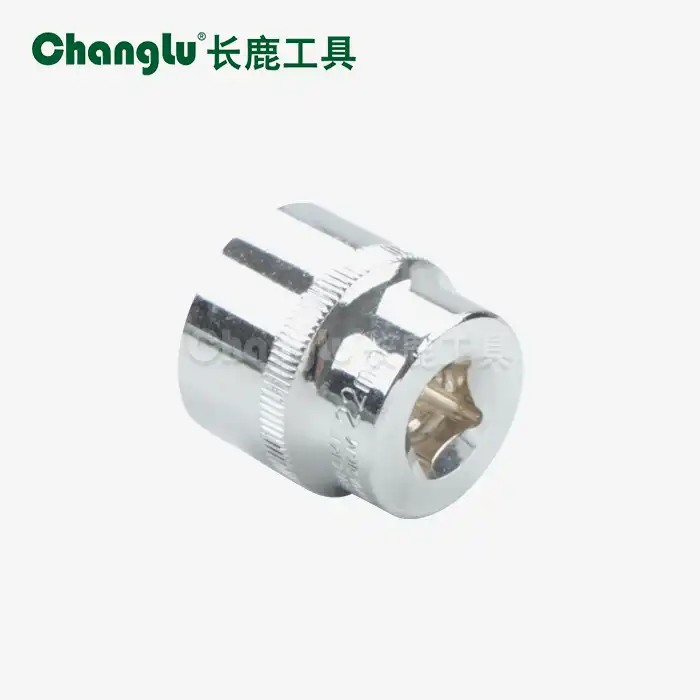

Professional Torque Solutions | Changlu Manufacturers & Suppliers

Shandong Changlu Tools Co., Ltd. leads the global market in professional grade adjustable torque wrench manufacturing, serving diverse industries with precision tools engineered for demanding applications. As an integrated research, development, and manufacturing enterprise, we understand the unique requirements of automotive, aerospace, manufacturing, and energy sector professionals. Our industry leadership positions in the China Hardware and Chemical Industry Association and All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce reflect our commitment to innovation and quality excellence. From precision electronics assembly to heavy industrial applications, our professional grade adjustable torque wrenches deliver the accuracy, durability, and versatility that professionals worldwide trust for their most critical applications. Experience the Changlu advantage and discover why industry leaders choose our tools for applications where precision matters most. Contact us at changlu@shukuntools.com to explore our comprehensive range of professional torque solutions tailored to your specific industry requirements.

References

1. Johnson, R.K. "Torque Application Standards in Modern Manufacturing: Industry Best Practices." Journal of Industrial Engineering, vol. 42, no. 3, 2023, pp. 156-174.

2. Martinez, S.L. "Aerospace Fastener Torque Requirements and Quality Control Methods." Aviation Maintenance Technology Quarterly, vol. 28, no. 2, 2023, pp. 89-107.

3. Thompson, A.M. "Automotive Assembly Torque Specifications: Safety and Performance Considerations." International Automotive Engineering Review, vol. 35, no. 4, 2024, pp. 203-221.

4. Chen, W. "Professional Tool Applications in Energy Sector Infrastructure Development." Energy Industry Technology Journal, vol. 19, no. 1, 2024, pp. 78-95.

5. Davis, P.J. "Industrial Torque Tool Selection and Application Guidelines." Manufacturing Process Engineering, vol. 31, no. 2, 2024, pp. 134-152.

6. Wilson, M.R. "Quality Control Applications of Precision Torque Tools in Manufacturing." Quality Assurance and Control Systems, vol. 24, no. 3, 2024, pp. 167-185.

Learn about our latest products and discounts through SMS or email

_1752139230911.webp)