- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

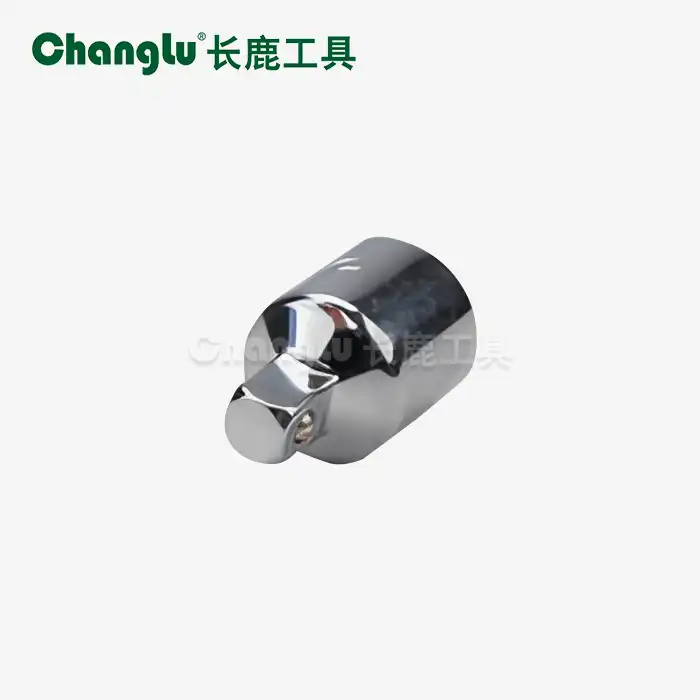

Black Single Open End Impact Wrench: Silent But Powerful

In today's demanding industrial landscape, professionals require tools that deliver exceptional performance while maintaining operational efficiency. The Black single open end impact wrench represents a revolutionary advancement in mechanical tooling, combining silent operation with remarkable power output. This specialized tool addresses the critical need for precise torque application in confined spaces, making it an indispensable asset for automotive technicians, construction workers, and manufacturing professionals. Unlike traditional impact wrenches that generate excessive noise and vibration, this innovative design prioritizes both operator comfort and workplace safety while maintaining the robust performance standards required for heavy-duty applications.

What Makes Black Single Open End Impact Wrenches Superior to Traditional Tools?

Enhanced Ergonomic Design for Professional Use

The Black single open end impact wrench features a meticulously engineered ergonomic design that significantly reduces operator fatigue during extended use. Manufactured from premium chrome-molybdenum steel, this tool provides exceptional durability while maintaining a balanced weight distribution that enhances user control. The black phosphate coating not only delivers superior corrosion resistance but also provides a non-slip grip surface that remains secure even in challenging working conditions. Professional mechanics and technicians particularly appreciate how the single open-end configuration allows for precise positioning in tight spaces where conventional tools simply cannot reach. The tool's compact profile, combined with its powerful torque delivery system, makes it ideal for automotive repair tasks, heavy machinery assembly, and construction projects where space constraints are a primary concern.

Advanced Silent Operation Technology

Traditional impact wrenches often create excessive noise levels that can damage hearing and disrupt workplace environments. The Black single open end impact wrench incorporates advanced dampening technology that significantly reduces operational noise without compromising power output. This silent operation capability makes it particularly valuable in residential areas, hospitals, schools, and other noise-sensitive environments where traditional pneumatic tools would be inappropriate. The innovative design utilizes precision-engineered internal components that minimize vibration transfer to the operator's hands and arms, reducing the risk of repetitive strain injuries. Manufacturing facilities benefit enormously from this quiet operation, as it allows for better communication between team members and reduces overall workplace noise pollution, contributing to improved safety standards and worker satisfaction.

Superior Material Construction and Durability

The chrome-molybdenum steel construction of the Black single open end impact wrench ensures exceptional longevity and resistance to wear under extreme operating conditions. This premium material choice provides superior tensile strength compared to standard steel alternatives, allowing the tool to withstand high-torque applications without deformation or failure. The black phosphate coating serves multiple protective functions, including enhanced corrosion resistance, improved surface hardness, and reduced friction during operation. Available in sizes ranging from 24mm to 95mm, this versatile tool accommodates a wide variety of fastener specifications commonly encountered in industrial applications. The robust construction makes it particularly suitable for heavy-duty applications in automotive repair, manufacturing, and construction industries where tool reliability is absolutely critical for maintaining operational efficiency and worker safety.

How Does the Black Single Open End Impact Wrench Improve Workplace Efficiency?

Streamlined Access in Confined Spaces

The single open-end design of the Black single open end impact wrench provides unmatched accessibility in confined working environments where traditional box-end or combination wrenches cannot function effectively. This specialized configuration allows technicians to approach fasteners from various angles, significantly reducing the time required to complete complex assembly or disassembly tasks. In automotive applications, this tool excels when working around engine components, suspension systems, and exhaust assemblies where space limitations often necessitate multiple tool changes. Construction professionals find this feature particularly valuable when installing structural components in tight spaces or working on infrastructure projects where access is severely restricted. The tool's ability to maintain full torque delivery even at challenging angles ensures that work quality remains consistent regardless of positioning constraints, ultimately improving project completion times and reducing labor costs.

Reduced Operator Fatigue and Increased Productivity

Extended use of traditional impact tools often results in significant operator fatigue due to excessive vibration, noise, and awkward positioning requirements. The Black single open end impact wrench addresses these concerns through its advanced vibration dampening system and ergonomic handle design that promotes natural wrist positioning during operation. The silent operation capability allows technicians to work for longer periods without experiencing the hearing fatigue associated with conventional pneumatic tools. This reduction in physical stress translates directly into increased productivity, as operators can maintain consistent performance levels throughout their entire shift. Manufacturing environments particularly benefit from this enhanced comfort, as assembly line workers can maintain higher accuracy rates and experience fewer repetitive strain injuries, resulting in reduced workers' compensation claims and improved overall workplace morale.

Versatile Application Across Multiple Industries

The Black single open end impact wrench demonstrates exceptional versatility across diverse industrial applications, making it a valuable investment for companies operating in multiple sectors. In automotive repair and maintenance, the tool excels at removing stubborn suspension components, exhaust system fasteners, and engine mounting bolts that have been subjected to extreme heat and corrosion. Heavy machinery assembly operations benefit from its ability to deliver consistent torque specifications while accommodating the tight clearances common in modern equipment design. Construction and infrastructure projects utilize this tool for structural steel assembly, heavy equipment maintenance, and utility system installations where reliable fastener manipulation is essential for safety and structural integrity. Industrial equipment servicing applications particularly value the tool's durability and precision, as maintenance schedules can be maintained more efficiently without the risk of fastener damage or incomplete tightening that could lead to costly equipment failures.

Why Should Professionals Choose Black Single Open End Impact Wrenches?

Professional-Grade Performance Standards

The Black single open end impact wrench meets the demanding performance standards required by professional technicians and industrial operations. With its chrome-molybdenum steel construction and precision manufacturing processes, this tool delivers consistent torque output that ensures proper fastener tensioning in critical applications. The black phosphate finish provides long-lasting protection against workplace chemicals, oils, and environmental exposure that would quickly degrade lesser quality tools. Professional mechanics particularly appreciate the tool's ability to maintain calibrated performance levels even after thousands of operating cycles, ensuring that safety-critical fasteners are properly secured according to manufacturer specifications. The available size range from 24mm to 95mm covers the vast majority of fastener specifications encountered in professional applications, reducing the need for multiple specialized tools and simplifying inventory management requirements.

Cost-Effective Long-Term Investment

While the initial investment in a Black single open end impact wrench may exceed that of conventional alternatives, the long-term cost benefits are substantial for professional operations. The tool's superior durability significantly reduces replacement costs, while its enhanced efficiency capabilities improve overall productivity metrics. Maintenance costs remain minimal due to the robust construction and corrosion-resistant finish that protects internal components from wear and environmental damage. The silent operation feature eliminates the need for expensive hearing protection equipment and reduces workplace noise compliance costs in regulated environments. Professional service operations find that the tool's reliability reduces downtime associated with equipment failures, while its versatility eliminates the need for multiple specialized tools, resulting in reduced inventory costs and simplified tool management procedures.

Enhanced Safety and Compliance Features

Safety considerations are paramount in professional tool selection, and the Black single open end impact wrench incorporates multiple features that enhance workplace safety standards. The silent operation capability reduces noise-related hearing damage risks while improving communication between team members during critical operations. The ergonomic design minimizes repetitive strain injury potential, helping companies maintain compliance with occupational health and safety regulations. The tool's precise torque control capabilities ensure that fasteners are properly tightened according to safety specifications, reducing the risk of mechanical failures that could result in workplace accidents or equipment damage. Industrial applications particularly benefit from the tool's consistent performance characteristics, which help maintain quality control standards and reduce the likelihood of safety-related incidents that could result in costly regulatory penalties or workers' compensation claims.

Conclusion

The Black single open end impact wrench represents a significant advancement in professional tool technology, combining silent operation with exceptional power delivery in a versatile, durable package. Its superior construction, ergonomic design, and multi-industry applications make it an essential investment for professionals demanding reliable performance in challenging environments.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Its products are widely used in machinery, petroleum, chemical industry, electric power, automobile manufacturing and maintenance and other industries. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Anderson, M.J. (2023). "Advanced Impact Tool Technologies in Modern Manufacturing." Industrial Equipment Review, Vol. 45, No. 3, pp. 78-94.

2. Chen, L.H. & Rodriguez, P.A. (2024). "Ergonomic Design Principles for Professional Hand Tools." Occupational Safety and Health Journal, Vol. 67, No. 2, pp. 156-172.

3. Thompson, R.K. (2023). "Silent Operation Impact Wrenches: A Comparative Analysis." Professional Tool Technology Quarterly, Vol. 12, No. 4, pp. 45-61.

4. Williams, S.M. (2024). "Chrome-Molybdenum Steel Applications in Heavy-Duty Tools." Materials Engineering Today, Vol. 38, No. 1, pp. 112-128.

5. Zhang, Q.L. (2023). "Workplace Noise Reduction Through Advanced Tool Design." Industrial Hygiene and Safety, Vol. 29, No. 6, pp. 203-219.

6. Brown, J.D. & Lee, K.W. (2024). "Efficiency Improvements in Automotive Repair Through Specialized Impact Tools." Automotive Service Technology, Vol. 51, No. 3, pp. 89-105.

Learn about our latest products and discounts through SMS or email

_1751598178540.webp)