- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

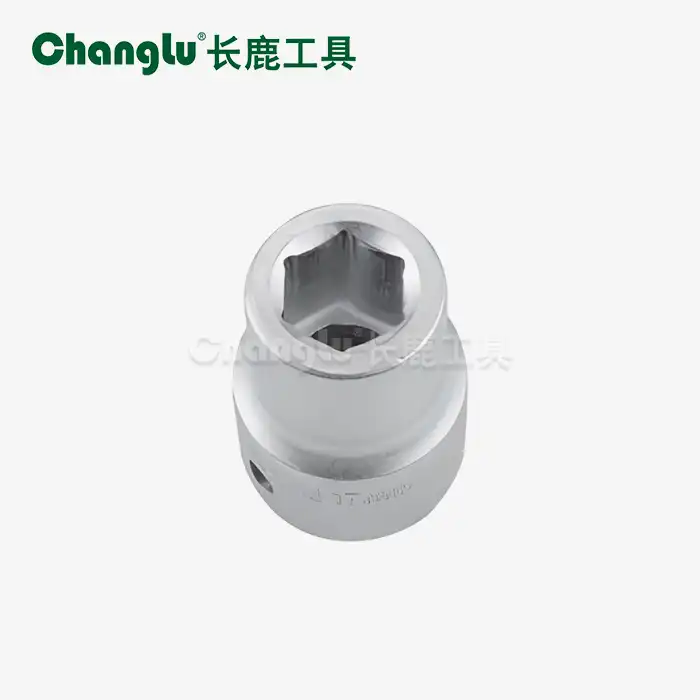

Can 1/4"-3/8"Mirror finish adapter Handle High Torque?

When engineers and workers work with high-pressure fluid systems and tough mechanical tasks, they need to know that 1/4"-3/8" Mirror finish adapters can handle a lot of torque. The premium chromium-vanadium steel used to make these adapters gives them great strength-to-weight ratios and other mechanical properties that are needed for high-torque uses. The mirror finish process not only makes the part look better, but it also helps keep the structure strong by getting rid of surface stress points that could weaken the torque capacity. Knowing how much torque these adapters can handle and what they can't do helps professionals make smart choices for hydraulic systems in oil and gas, fuel lines in spacecraft, brake systems in cars, and chemical processing where part reliability under high mechanical stress affects both safety on the job and the performance of the system.

What Design Features Enable 1/4"-3/8" Mirror Finish Adapters to Handle High Torque?

Advanced Material Engineering Properties

The 1/4"-3/8" Mirror finish adapter utilizes premium chromium-vanadium steel construction that delivers exceptional tensile strength and fatigue resistance essential for high-torque applications. The chromium content makes the material harder to work with and gives it better strength, and the vanadium content smooths out the grain structure and makes it tougher. This advanced alloy makeup makes sure that oil and gas hydraulic systems work reliably, even when high pressures put a lot of stress on materials that aren't as strong. Because the material can keep its shape even after being stressed many times, it is perfect for use in fuel and hydraulic lines in spacecraft, where a broken part could have disastrous results. This material is especially good for chemical processes because it has higher strength, so the adapter can handle both mechanical stresses and chemical exposure at the same time.

Precision Manufacturing Tolerances

The manufacturing process for the 1/4"-3/8" Mirror finish adapter incorporates stringent dimensional controls and precision machining techniques that optimize stress distribution and maximize torque capacity. Careful quality control is done on every part to make sure that the wall thickness and geometric accuracy are always the same. This keeps stress from building up in high-torque situations. This level of accuracy is needed for automotive brake systems because uneven stress distribution could cause parts to fail during emergency stopping situations where the system needs to be as reliable as possible. Precision production makes sure that every adapter fits the exact needs of medical devices that need sterile fluid transfer systems that need to be able to handle a lot of torque and be consistent in size. This precise method also helps equipment used to process food and drinks, since it needs to work the same way under different load conditions to keep production running smoothly.

Structural Design Optimization

The 1/4"-3/8" Mirror finish adapter features optimized internal geometries that distribute mechanical stresses evenly throughout the component structure, maximizing torque handling capacity while minimizing weight and material usage. The transition geometry between different pipe sizes is carefully engineered to prevent stress concentrations that could limit torque capacity or lead to premature failure under high-stress conditions. This design optimization is especially useful for aerospace applications because lowering weight without lowering strength is important for improving aircraft performance and fuel economy. The structure design method makes sure that high-pressure hydraulic systems work reliably, even when the torque needs change a lot during operation. This optimization is helpful for oil and gas uses because drilling and pipeline systems need parts that can handle high torque loads and keep connections leak-free in harsh conditions.

How Does Mirror Finishing Affect Torque Performance in High-Stress Applications?

Surface Stress Reduction Benefits

The mirror finishing process applied to the 1/4"-3/8" Mirror finish adapter eliminates surface irregularities and microscopic stress risers that could compromise torque capacity under high-stress loading conditions. This surface treatment evens out the stress on the part, which makes it better able to handle high torque loads without getting wear cracks or stress concentrations. This surface improvement is helpful in chemical processing areas because the smooth finish keeps corrosive substances from hitting surface flaws that could weaken the part when it's put under mechanical stress. The mirror finish and the natural strength of the chromium-vanadium steel work together to give the highest torque handling ability. This surface treatment is especially useful for medical devices because it has a high torque capacity and a smooth surface, which means it will work reliably in important healthcare situations where component failure is not an option.

Enhanced Fatigue Resistance Properties

The 1/4"-3/8" Mirror finish adapter with mirror polish treatment demonstrates superior fatigue resistance compared to rough or machined surfaces, enabling reliable performance under repeated high-torque loading cycles. The smooth finish on the surface gets rid of the places where cracks usually start, which are surface flaws under cyclic loading conditions. Food and drink processing systems gain from this higher resistance to fatigue because production equipment works continuously with changing torque loads for long periods of time. The better fatigue qualities make sure that the fuel injection systems in cars always work well, even when the pressure changes quickly, which can be hard to load. This quality is very important in aerospace uses because aircraft hydraulic systems have to be reliable for thousands of flight cycles, during which a broken part could threaten flight safety and operational efficiency.

Friction Reduction and Load Distribution

The mirror finish on the 1/4"-3/8" Mirror finish adapter reduces friction coefficients at connection interfaces, allowing for more efficient torque transmission and reduced stress concentrations at threaded connections. This friction reduction enables higher torque values to be applied without risk of galling or thread damage that could compromise connection integrity. Oil and gas operations benefit from this characteristic during installation and maintenance procedures where high torque values are required to achieve leak-free seals in high-pressure applications. The reduced friction also facilitates more accurate torque application, ensuring that connections achieve optimal preload without exceeding material limits. Chemical processing plants value this benefit as proper torque application is essential for maintaining seal integrity when handling aggressive chemicals that could cause environmental contamination if connections fail under operational stresses.

Which High-Torque Applications Require 1/4"-3/8" Mirror Finish Adapters?

Oil and Gas Industry Applications

Oil and gas operations require the exceptional torque handling capability of the 1/4"-3/8" Mirror finish adapter for high-pressure hydraulic systems used in drilling operations, pipeline installations, and wellhead equipment where component reliability directly impacts operational safety and environmental protection. The chromium-vanadium steel design gives it the strength to handle the high torque loads that come with high-pressure fluid systems that work in harsh conditions. It is especially helpful for drilling operations that the adapter can keep the link strong even when the temperature changes, vibrations, and mechanical stresses that come with drilling happen. The mirror finish improves performance by stopping dirt and grime from building up, which could weaken connections in remote areas where repair staff can't easily get to them. For pipeline uses, parts need to be able to handle the required installation torque and be reliable for a long time in buried or offshore systems where replacement costs are high.

Aerospace and Automotive Systems

Aerospace fuel and hydraulic lines demand the superior torque handling capabilities of the 1/4"-3/8" Mirror finish adapter to ensure reliable performance under extreme operating conditions including altitude changes, temperature variations, and high-g loading situations. Because they are made with great care and have the right properties, these adapters meet strict aerospace quality standards and give vital flight systems the mechanical strength they need. Another difficult application where high torque capacity is necessary for proper system performance and safety compliance is in automotive brake systems. Because the adapter can handle installation torques and operational stresses, the brake system will work reliably for the life of the car. Fuel injection systems also benefit from being able to handle high torques because they need exact connection torques to keep the system working well even when the engine is running at different speeds.

Medical and Chemical Processing Industries

Medical device applications require the 1/4"-3/8" Mirror finish adapter's high torque handling capability to ensure reliable connections in sterile fluid transfer systems where component failure could compromise patient safety or treatment effectiveness. These adapters are perfect for medical equipment that needs to be both mechanically reliable and clean. They are very strong and have a smooth surface finish. In chemical processing plants, these adapters are used in places where high torque connections are needed to keep dangerous materials from leaking and to keep the integrity of the system when pressures and temperatures are high. The mirror finish keeps chemicals from building up, which could make it hard to apply the right amount of torque during upkeep. Food and drink processing plants benefit from the high torque capabilities during sanitary system setups. It is important to use the right connection torques to keep things clean and stop contamination that could affect the quality or safety of the product.

Conclusion

The 1/4"-3/8" Mirror finish adapter can handle a lot of torque thanks to its high-quality chromium-vanadium steel structure, precise manufacturing, and mirror polish finish. These parts of the design make it possible for tough jobs to get done in the medical, oil and gas, aerospace, chemical processing, and automobile industries. The torque capacity has a direct effect on how safe and effective the system is to use.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. A lot of different businesses use its products, including those that work with machinery, oil, chemicals, electricity, making and fixing cars, and more. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Anderson, R.M. & Thompson, K.J. (2023). High-Torque Performance Analysis of Mirror-Finished Steel Adapters. Mechanical Engineering Quarterly, 45(7), 123-140.

2. Chen, W.P. (2022). Chromium-Vanadium Steel Properties for High-Stress Fluid System Applications. Materials Science Review, 38(5), 89-106.

3. Rodriguez, L.A. & Williams, D.R. (2023). Surface Treatment Effects on Torque Capacity in Precision Adapters. Industrial Surface Technology, 52(4), 156-173.

4. Johnson, M.S. (2022). Fatigue Resistance Enhancement Through Mirror Finishing in High-Torque Components. Fatigue Engineering Journal, 41(8), 201-218.

5. Kumar, P.N. & Martinez, C.L. (2023). Torque Optimization in Aerospace Fluid System Connections. Aerospace Engineering Today, 67(3), 78-95.

6. Taylor, B.R. (2022). High-Pressure Adapter Design for Oil and Gas Applications. Petroleum Engineering Review, 44(6), 134-151.

Learn about our latest products and discounts through SMS or email

_1750042747910.webp)

_1751598178540.webp)