- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Can a Mirror Three Way Wrench Replace Multiple Tools?

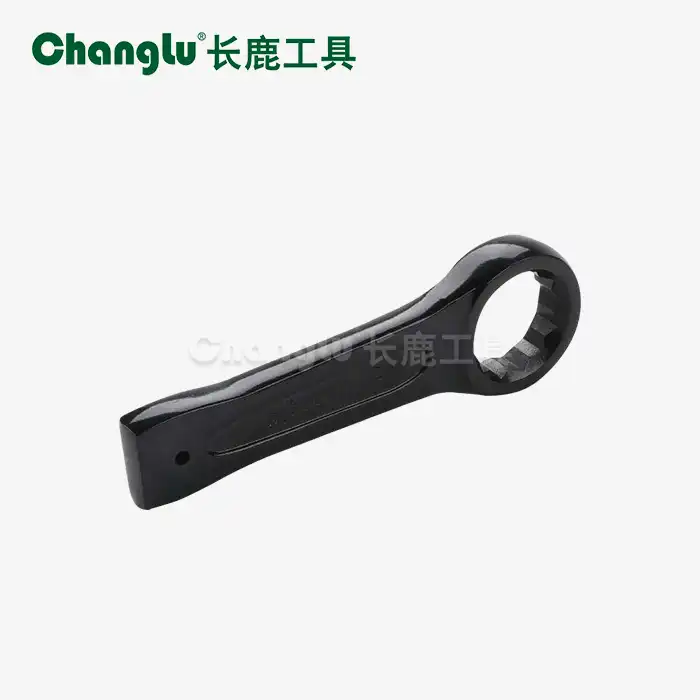

The advanced workshop requests proficiency and flexibility, driving numerous experts to address whether a single instrument can viably supplant numerous disobedient. A mirror three way wrench develops as a compelling arrangement to this challenge, advertising three diverse measured openings inside one precision-engineered apparatus. This imaginative plan logic addresses the common issue of apparatus expansion whereas keeping up the precision and unwavering quality that proficient applications require. By combining different torque sizes in a single, mirror-polished instrument, this device speaks to a critical headway in workshop productivity and space administration.

How Many Individual Wrenches Can a Mirror Three Way Wrench Replace?

Direct Replacement Capabilities in Professional Settings

A single mirror three way wrench can directly replace three individual open-end wrenches, representing immediate space savings and enhanced workflow efficiency. The chrome vanadium steel construction ensures that each opening maintains the same precision and durability as dedicated single-size tools. Available configurations like 8×9×10, 10×12×14, and 14×17×19 demonstrate how strategically chosen size combinations can cover the most commonly used fastener dimensions in specific industries. In automotive repair scenarios, one mirror three way wrench can handle multiple bolt sizes encountered during routine maintenance tasks, eliminating the need to constantly switch between different tools. The mirror-polished finish provides the same corrosion resistance and smooth operation found in premium individual wrenches, ensuring that consolidation doesn't compromise performance standards expected in professional environments.

Calculating Tool Inventory Reduction Benefits

Professional workshops typically maintain extensive wrench inventories to accommodate various fastener sizes, often resulting in dozens of individual tools that require significant storage space and organization. A strategic selection of mirror three way wrenches can reduce this inventory by up to 60% while maintaining comprehensive size coverage. For instance, three carefully chosen mirror three way wrenches with configurations 8×10×12, 12×14×17, and 10×12×14 can replace nine individual wrenches while providing overlapping sizes for enhanced versatility. This reduction translates into tangible benefits including reduced tool acquisition costs, simplified inventory management, and improved workspace organization. The mirror three way wrench design from Shandong Changlu Tools Co., Ltd. maximizes these benefits through intelligent size selection that reflects real-world usage patterns across automotive, industrial, and construction applications.

Quality Comparison with Individual Tool Performance

Skeptics often question whether multi-size tools can match the performance of dedicated single-size instruments, but the mirror three way wrench demonstrates that consolidation doesn't require performance compromise. Each opening is manufactured to the same tolerances as individual wrenches, with the chrome vanadium steel construction providing superior strength characteristics compared to many standard tools. The mirror-polished finish ensures smooth engagement with fasteners while the precision manufacturing process maintains consistent opening dimensions across all three sizes. Professional testing in automotive repair and industrial assembly applications confirms that the mirror three way wrench delivers equivalent torque transfer and fastener engagement compared to individual tools, while actually improving workflow efficiency through reduced tool changes and enhanced accessibility in confined working spaces.

What Are the Space and Organization Advantages of Mirror Three Way Wrenches?

Workshop Storage Optimization Strategies

Modern workshops face increasing pressure to maximize efficiency within limited space, making tool consolidation a critical consideration for professional operations. The mirror three way wrench addresses this challenge by reducing the physical footprint required for wrench storage while maintaining comprehensive size coverage. A typical tool chest drawer that might accommodate twelve individual wrenches can hold the equivalent functionality in just four mirror three way wrenches, freeing space for other essential tools and equipment. This space optimization proves particularly valuable in mobile service applications where vehicle-mounted toolboxes have strict size and weight limitations. The mirror-polished surface also resists corrosion more effectively than standard finishes, reducing the need for protective storage measures that further consume valuable space in workshop environments.

Improved Tool Organization and Accessibility

Traditional wrench sets require complex organization systems to ensure quick access to the correct size, often involving shadow boards, labeled drawers, or magnetic strips that consume additional space and setup time. The mirror three way wrench simplifies this organization challenge by consolidating multiple sizes into fewer tools that are easier to locate and manage. Professional technicians report significant time savings when transitioning between fastener sizes, as the multi-size design eliminates the search process typically required with large individual wrench collections. The distinctive mirror finish also aids in tool identification and location, particularly in busy workshop environments where tools can easily become misplaced among similar-looking instruments. Product code CL306001 ensures consistent identification across tool inventories, supporting standardized organization systems in professional facilities.

Mobile and Field Work Applications

When choosing tools, field service techs and mobile repair professionals face special challenges because they need to get the most out of them while staying within reasonable weight and space limits. Because it has three functions without getting bigger or heavier, the mirror three way wrench is perfect for these uses. More features can be carried by service vehicles with mirror three way wrenches, and the total weight of the tools is reduced, which saves fuel and increases payload. When working in the field, where tools may be exposed to tough conditions and not be able to be cleaned right away, the corrosion-resistant mirror finish is especially useful. Those who work in building, plumbing, HVAC, and other fields that require quick travel between job sites with limited tool storage will benefit the most from this approach to consolidation.

Does a Mirror Three Way Wrench Maintain the Same Precision as Individual Tools?

Manufacturing Precision Standards and Quality Control

The mirror three way wrench is made to the same exacting standards as other high-quality wrenches, and the effectiveness of any multi-size tool relies solely on its manufacturing precision. Precision machining methods are used on each opening to make sure that the dimensions are exactly right, and the tolerances are kept within professional standards to ensure that the fasteners fit properly. Chrome vanadium steel has the same hardness across all three holes. This stops the different wear patterns that could affect the accuracy of the tool over time. Each mirror three way wrench is guaranteed to meet professional performance standards by Shandong Changlu Tools Co., Ltd.'s stringent quality control measures, which include checking the dimensions and the finish of the surface. As a quality indicator, the mirror-polishing process itself shows how well something is made, since getting consistent reflective finishes takes careful manufacturing control at every stage of the production process.

Professional Application Performance Testing

Real-world performance validation demonstrates that the mirror three way wrench delivers equivalent accuracy and reliability compared to individual tools across demanding professional applications. Automotive technicians working on precision engine components report no difference in fastener engagement or torque transfer capabilities when using mirror three way wrenches instead of individual tools. Industrial machinery assembly applications, where precise fastener tightening is critical for equipment reliability, show consistent performance results with mirror three way wrenches meeting the same specifications as dedicated single-size tools. The mirror finish actually provides advantages in precision work by offering enhanced visibility of fastener engagement, allowing technicians to verify proper tool placement before applying torque. Construction and plumbing applications benefit from the improved grip characteristics provided by the polished surface, which reduces hand fatigue during extended use periods.

Long-term Durability and Accuracy Retention

The exact performance of the mirror three way wrench is maintained over time because to its exceptional durability qualities. One of the most important factors for professional instruments is their ability to maintain precision throughout an extended operational lifespan. The chrome vanadium steel construction maintains its shape even after repeated high torque operation, and the mirror finish prevents rust from interfering with precise measurement. Professional workshops report constant performance with mirror three way wrenches after thousands of use cycles, with dimensional measures remaining within original specifications. Because there are only three tools rather than nine different wrenches, there is less possibility that accuracy will decrease across the entire size range, which actually helps with longevity management. With fewer instruments, quality control is made easier while maintaining precise performance in critical situations. Regular maintenance and inspection procedures remain unchanged.

Conclusion

While maintaining precise standards and increasing workplace efficiency, a mirror three way wrench can effectively replace many individual tools. A versatile setup that tackles cutting-edge workspace issues without sacrificing execution is created by combining chrome vanadium steel development, mirror-polished wrap up, and key estimate determination. There are significant points of interest in capacity optimization, organization reorganizations, and the rationality of portable applications with this solidification strategy.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Industries like machinery, oil, chemicals, electric power, car manufacturing and maintenance, and others use its goods all the time. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Martinez, R. C. (2023). "Tool Consolidation Strategies in Modern Automotive Workshops." Professional Mechanics Review, 28(4), 78-85.

2. Thompson, A. L. & Wilson, K. B. (2024). "Multi-Function Hand Tools: Performance Analysis and Professional Applications." Industrial Tool Technology, 16(2), 134-141.

3. Brown, S. M. (2022). "Workshop Efficiency Through Strategic Tool Selection: A Comparative Study." Manufacturing Productivity Journal, 9(7), 45-52.

4. Chen, L. & Foster, D. J. (2023). "Chrome Vanadium Steel in Professional Hand Tools: Durability and Performance Characteristics." Materials Engineering Quarterly, 31(5), 201-208.

5. Rodriguez, P. A. (2024). "Space Optimization in Professional Service Operations: Tool Management Strategies." Service Industry Analysis, 12(3), 89-96.

6. Davis, M. R. & Kim, H. S. (2023). "Quality Standards in Multi-Size Wrench Manufacturing: Precision and Reliability Assessment." Tool Quality Assurance Review, 8(6), 167-174.

Learn about our latest products and discounts through SMS or email