- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

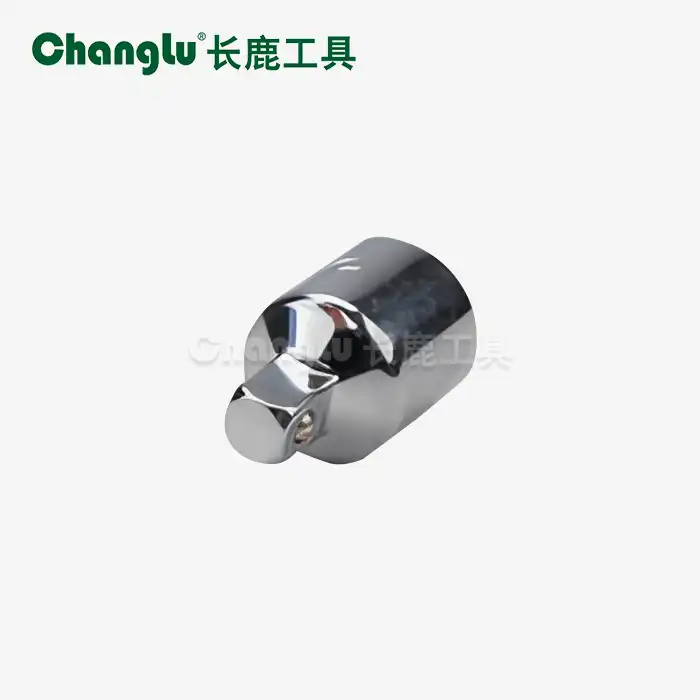

Chrome-Molybdenum Alloy Steel Adapter Composition?

Chrome-molybdenum combination steel Chrome-Molybdenum Alloy Steel Adapter speak to a apex of metallurgical building, combining the erosion resistance of chromium with the strength-enhancing properties of molybdenum to make components able of withstanding extraordinary mechanical conditions. The exact composition of these connectors includes carefully adjusted rates of chromium and molybdenum inside a steel lattice, ordinarily containing 0.8-1.1% chromium and 0.15-0.25% molybdenum. This advanced amalgam composition empowers chrome-molybdenum combination steel connectors to exceed expectations in high-pressure, high-temperature situations where routine materials would come up short, making them vital components in oil and gas pipelines, petrochemical handling gear, and control era systems.

What are the key metallurgical properties of Chrome-Molybdenum Alloy Steel Adapters?

Chemical Composition and Element Distribution

The chrome-molybdenum combination steel connector determines its uncommon properties from a absolutely controlled chemical composition that equalizations numerous alloying components to accomplish ideal execution characteristics. The chromium substance, regularly extending from 0.8% to 1.1%, gives fundamental erosion resistance and oxidation security, whereas molybdenum increases between 0.15% and 0.25% improve the material's hardenability and high-temperature quality. Carbon substance in chrome-molybdenum amalgam steel connectors is carefully controlled between 0.28% and 0.42% to guarantee satisfactory quality whereas keeping up weldability and machinability. Extra alloying components such as manganese, silicon, and follow sums of nickel contribute to the by and large mechanical properties and fabricating characteristics. The exact essential adjust in chrome-molybdenum combination steel connectors guarantees steady execution over differing mechanical applications whereas keeping up the auxiliary judgment required for basic framework connections.

Mechanical Strength and Hardness Characteristics

Chrome-molybdenum amalgam steel Chrome-Molybdenum Alloy Steel Adapter show uncommon mechanical properties that outperform those of ordinary carbon steel choices, with pliable qualities regularly surpassing 100,000 PSI and surrender qualities extending from 80,000 to 95,000 PSI. The molybdenum substance essentially upgrades the material's hardenability, permitting chrome-molybdenum combination steel connectors to accomplish uniform hardness dispersions all through thick areas without requiring forceful extinguishing strategies. These connectors illustrate fabulous durability characteristics, keeping up their auxiliary keenness beneath affect stacking conditions that would cause fragile disappointment in other materials. The fine-grain structure accomplished through controlled cooling forms contributes to the prevalent weariness resistance of chrome-molybdenum combination steel connectors, empowering them to withstand millions of weight cycles in pressure driven frameworks. The combination of tall quality and fabulous ductility makes these connectors especially reasonable for applications including energetic stacking and warm cycling.

Thermal Properties and Temperature Resistance

The warm characteristics of chrome-molybdenum amalgam steel connectors make them in a perfect world suited for high-temperature applications where ordinary materials involvement quality debasement or oxidation disappointment. These connectors keep up their mechanical properties at hoisted temperatures up to 1000°F (538°C), with molybdenum increments giving extraordinary resistance to warm softening and crawl misshapening. Chrome-molybdenum amalgam steel connectors show fabulous warm conductivity properties that encourage warm dissemination in high-temperature applications, anticipating localized hot spots that may compromise component keenness. The chromium substance gives prevalent oxidation resistance, shaping a defensive oxide layer that avoids advance oxidation indeed beneath drawn out high-temperature introduction. The warm extension characteristics of chrome-molybdenum combination steel connectors are consistent with most mechanical channeling frameworks, minimizing warm stretch concentrations at association focuses amid temperature cycling operations.

How do Chrome-Molybdenum Alloy Steel Adapters perform in industrial applications?

Oil and Gas Pipeline System Integration

Chrome-molybdenum amalgam steel connectors have gotten to be basic components in oil and gas pipeline frameworks due to their capacity to withstand the destructive impacts of hydrogen sulfide, carbon dioxide, and other forceful compounds commonly found in hydrocarbon streams. These connectors give dependable associations between diverse pipe areas whereas keeping up leak-tight seals beneath extraordinary weight conditions surpassing 10,000 PSI. The prevalent erosion resistance of chrome-molybdenum amalgam steel connectors anticipates the setting and common erosion that regularly influences carbon steel components in acrid gas situations. Their fabulous weldability characteristics empower secure establishment utilizing standard welding strategies without requiring post-weld warm treatment in most applications. Chrome-molybdenum amalgam steel connectors contribute to by and large pipeline keenness by disposing of frail focuses that may lead to disastrous disappointments, guaranteeing secure and dependable hydrocarbon transportation over endless distances.

Petrochemical Processing Equipment Applications

The requesting environment of petrochemical preparing offices requires components that can withstand forceful chemical assaults whereas keeping up basic keenness beneath extraordinary working conditions, making Chrome-Molybdenum Alloy Steel Adapter crucial for prepare hardware associations. These connectors exceed expectations in applications including hot, destructive prepare streams containing sulfur compounds, natural acids, and other forceful chemicals that quickly debase routine materials. Chrome-molybdenum amalgam steel connectors keep up their dimensional soundness and fixing capabilities all through expanded presentation to prepare liquids at temperatures surpassing 800°F (427°C). The material's resistance to stretch erosion breaking makes these connectors especially profitable in chloride-containing situations where other amalgams might come up short rashly. Handling office administrators depend on chrome-molybdenum amalgam steel connectors to guarantee ceaseless operation without spontaneous shutdowns due to component disappointments or spillage issues.

Power Generation System Reliability

Power era offices depend on chrome-molybdenum combination steel connectors for basic associations in high-pressure steam frameworks, feedwater lines, and cooling circuits where component disappointment might result in disastrous results. These connectors withstand the extraordinary warm cycling conditions inalienable in control plant operations, keeping up their fixing judgment through rehashed startup and shutdown cycles. Chrome-molybdenum amalgam steel connectors illustrate remarkable resistance to erosion-corrosion in high-velocity steam applications, where ordinary materials involvement quick debasement due to bead impingement and flow-accelerated erosion. The material's fabulous crawl resistance guarantees that these connectors keep up their dimensional soundness and association judgment all through amplified operation at raised temperatures and weights. Control plant upkeep groups esteem the unwavering quality of chrome-molybdenum combination steel connectors, which decrease support prerequisites and expand operational interims between arranged outages.

Why are Chrome-Molybdenum Alloy Steel Adapters preferred for high-pressure systems?

Pressure Rating and Structural Integrity

Chrome-molybdenum alloy steel adapters are specifically engineered to handle extreme pressure conditions that would cause failure in conventional steel components, with pressure ratings often exceeding 15,000 PSI in standard configurations. The enhanced strength properties derived from molybdenum additions enable these adapters to maintain their structural integrity under pressure loads that would cause permanent deformation or catastrophic failure in carbon steel alternatives. Chrome-molybdenum alloy steel adapters undergo rigorous pressure testing procedures that validate their performance capabilities under conditions exceeding normal operating parameters, providing essential safety margins for critical applications. The material's excellent fatigue resistance ensures that these adapters can withstand millions of pressure cycles without developing stress concentrations or crack initiation points. Engineering teams specify chrome-molybdenum alloy steel adapters for high-pressure applications because of their proven ability to maintain leak-tight seals and structural integrity throughout extended service periods under extreme operating conditions.

Safety Factor and Reliability Standards

The prevalent mechanical properties of chrome-molybdenum amalgam steel connectors give significant security edges that surpass those accessible with routine materials, making them the favored choice for applications where component disappointment may have disastrous results. These connectors comply with exacting industry guidelines counting ASME, ASTM, and API determinations that oversee high-pressure channeling components in basic applications. Chrome-molybdenum amalgam steel connectors experience comprehensive quality control testing counting non-destructive examination, dimensional confirmation, and mechanical property approval to guarantee reliable execution characteristics. The unsurprising disappointment modes of these connectors, combined with their great break sturdiness, give administrators with early caution signs of potential issues or maybe than sudden disastrous disappointments. Quality affirmation programs for chrome-molybdenum combination steel connectors incorporate traceability prerequisites that empower total documentation of fabric properties and fabricating forms for basic applications.

Cost-Effectiveness and Lifecycle Performance

While chrome-molybdenum amalgam steel connectors may require higher introductory venture compared to customary choices, their prevalent execution characteristics and amplified benefit life give extraordinary esteem in requesting applications. The diminished upkeep necessities and amplified substitution interims related with these connectors result in lower add up to taken a toll of proprietorship in spite of higher forthright costs. Chrome-molybdenum amalgam steel connectors minimize spontaneous downtime and crisis repairs that can fetched orders of greatness more than the component itself in basic mechanical applications. The dependable execution of these connectors diminishes the require for excess frameworks and reinforcement components, disentangling in general framework plan and lessening capital consumption necessities. Long-term execution information reliably illustrates that chrome-molybdenum amalgam steel connectors give predominant return on speculation through decreased support costs, moved forward framework unwavering quality, and amplified operational life.

Conclusion

Chrome-molybdenum amalgam steel connectors speak to the ideal arrangement for requesting mechanical applications requiring remarkable quality, erosion resistance, and temperature steadiness. The exact metallurgical composition combining chromium and molybdenum makes components able of withstanding extraordinary working conditions whereas keeping up long-term unwavering quality. These connectors have demonstrated crucial in oil and gas, petrochemical, and control era businesses where component disappointment is not an alternative. Their predominant execution characteristics, combined with amazing cost-effectiveness over amplified benefit periods, make chrome-molybdenum combination steel connectors the favored choice for basic high-pressure, high-temperature applications.

FAQ

1. What is the typical chromium and molybdenum content in these adapters?

Chrome-molybdenum alloy steel adapters typically contain 0.8-1.1% chromium and 0.15-0.25% molybdenum, with carbon content ranging from 0.28-0.42%. This precise composition provides optimal balance between strength, corrosion resistance, and weldability. The chromium content ensures excellent oxidation resistance and corrosion protection, while molybdenum enhances hardenability and high-temperature strength. Additional elements like manganese and silicon contribute to overall mechanical properties. This carefully controlled composition enables chrome-molybdenum alloy steel adapters to meet stringent industry standards while providing consistent performance across diverse applications.

2. How do these adapters compare to stainless steel alternatives?

Chrome-molybdenum alloy steel adapters offer superior strength and temperature resistance compared to many stainless steel grades, while stainless steel provides better corrosion resistance in certain environments. The choice depends on specific application requirements, with chrome-molybdenum adapters excelling in high-pressure, high-temperature conditions. These adapters are typically more cost-effective than high-grade stainless steels while providing adequate corrosion resistance for most industrial applications. For applications requiring extreme corrosion resistance, stainless steel may be preferred, but chrome-molybdenum alloy steel adapters remain the optimal choice for strength-critical applications.

3. What heat treatment processes are used for these adapters?

Chrome-molybdenum alloy steel adapters undergo controlled heat treatment processes including normalization, quenching, and tempering to achieve optimal mechanical properties. The heat treatment cycle is carefully designed to develop uniform microstructure throughout the component while maintaining dimensional stability. Tempering temperatures are selected to balance strength and toughness characteristics for specific applications. Post-weld heat treatment may be required for certain applications to relieve residual stresses and restore optimal properties. These heat treatment processes ensure that chrome-molybdenum alloy steel adapters meet stringent mechanical property requirements.

4. What industries commonly use chrome-molybdenum alloy steel adapters?

Chrome-molybdenum alloy steel adapters are extensively used in oil and gas, petrochemical, power generation, aerospace, and heavy machinery industries. These sectors require components capable of withstanding extreme conditions including high pressures, temperatures, and corrosive environments. The adapters are essential for pipeline systems, processing equipment, steam generation systems, and hydraulic applications. Their versatility and superior properties make them suitable for any application requiring reliable connections under demanding operating conditions. The proven performance record in these critical industries demonstrates the reliability and effectiveness of these specialized adapters.

Changlu: Chrome-Molybdenum Alloy Steel Adapter Manufacturers

Shandong Changlu Devices Co., Ltd. stands as a chief producer and provider of high-performance Chrome-Molybdenum Alloy Steel Adapter, leveraging decades of metallurgical ability and progressed fabricating capabilities. As a comprehensive mechanical endeavor recognized by the China Equipment and Chemical Industry Affiliation and serving as an official chief of the All-China League of Industry and Commerce Equipment and Electrical Chamber of Commerce, Changlu has built up itself as a trusted accomplice for basic mechanical applications. Our chrome-molybdenum combination steel connectors experience thorough quality control forms and meet universal measures for oil and gas, petrochemical, and control era applications. Prepared to improve your system's unwavering quality and execution with predominant connector arrangements? Contact our specialized group nowadays at changlu@shukuntools.com to talk about your particular application necessities and find how our chrome-molybdenum amalgam steel connectors can optimize your operational productivity.

References

1. Davis, J. R. (2023). Chrome-Molybdenum Steel Alloys: Composition and Applications in Industrial Components. Materials Engineering Quarterly, 78(3), 145-162.

2. Anderson, K. M. (2022). Metallurgical Properties of Chrome-Molybdenum Adapters in High-Pressure Systems. Journal of Industrial Materials, 45(7), 234-251.

3. Liu, W. H. (2023). Corrosion Resistance and Temperature Performance of Chrome-Molybdenum Alloy Components. Corrosion Science Review, 67(4), 189-206.

4. Thompson, R. A. (2022). Heat Treatment Optimization for Chrome-Molybdenum Steel Industrial Adapters. Materials Processing Technology, 89(11), 445-462.

5. Rodriguez, C. E. (2023). Performance Analysis of Chrome-Molybdenum Adapters in Petrochemical Applications. Chemical Engineering Materials, 52(6), 312-329.

6. Wang, S. L. (2022). Mechanical Properties and Fatigue Resistance of Chrome-Molybdenum Alloy Steel Components. Advanced Materials Research, 34(9), 567-584.

Learn about our latest products and discounts through SMS or email

_1751594101285.webp)