- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Chrome vanadium vs carbon steel universal joints - which lasts longer?

The comparison between chrome vanadium and carbon steel all inclusive joints speaks to a basic choice point for engineers and support experts over different mechanical applications.Chrome vanadium steel universal joints have developed as the prevalent choice for requesting situations, advertising uncommon solidness, erosion resistance, and operational life span that altogether outperforms conventional carbon steel choices. Understanding the principal contrasts in fabric properties, wear characteristics, and execution beneath stretch makes a difference experts make educated choices when selecting components for car transmissions, overwhelming apparatus, agrarian executes, and mechanical robotization frameworks where unwavering quality specifically impacts operational efficiency.

What Makes Chrome Vanadium Steel Universal Joint More Durable Than Carbon Steel?

Advanced Metallurgical Properties and Composition

Chrome vanadium steel widespread joints illustrate prevalent solidness through their progressed metallurgical composition that joins chromium and vanadium combination components, making upgraded quality characteristics inaccessible in standard carbon steel options. The chromium substance gives extraordinary erosion resistance whereas vanadium increments hardness and wear resistance, making chrome vanadium steel widespread joints perfect for unforgiving mechanical situations. These metallurgical changes decipher into expanded benefit life over requesting applications counting car transmissions, development hardware, and aviation frameworks where component disappointment may result in expensive downtime. The modern combination composition empowers chrome vanadium steel widespread joints to keep up basic keenness beneath high-stress conditions that would compromise carbon steel components, giving quantifiable fetched reserve funds through diminished substitution recurrence and improved operational reliability.

Enhanced Heat Treatment Response and Hardness

The heat treatment response of chrome vanadium steel universal joints significantly exceeds carbon steel capabilities, enabling superior hardness levels and uniform grain structure that enhance wear resistance and fatigue life. Professional heat treatment processes can achieve optimal hardness distribution throughout chrome vanadium steel universal joints, ensuring consistent performance characteristics across all component surfaces. This enhanced hardenability proves particularly beneficial in heavy machinery applications where variable load conditions create complex stress patterns that challenge material limits. The superior heat treatment response enables chrome vanadium steel universal joints to achieve hardness levels that maintain effectiveness throughout extended operational cycles, while carbon steel alternatives often experience hardness degradation that compromises performance and reduces service life in demanding industrial applications.

Superior Fatigue Resistance and Stress Distribution

Chrome vanadium steel universal joints exhibit exceptional fatigue resistance through optimized stress distribution characteristics that prevent crack initiation and propagation under cyclic loading conditions common in industrial robotics and automation systems. The alloy composition creates uniform stress distribution patterns that eliminate stress concentration points typically found in carbon steel components, significantly extending operational life under repetitive loading scenarios. Agricultural implements benefit tremendously from this fatigue resistance, as chrome vanadium steel universal joints maintain reliable operation throughout seasonal use cycles that would compromise carbon steel alternatives. The superior stress distribution capabilities enable these components to handle variable torque applications while maintaining dimensional stability and operational precision essential for automated manufacturing processes and precision agricultural equipment.

How Do Chrome Vanadium Steel Universal Joints Perform Under Extreme Conditions?

Corrosion Resistance in Harsh Environments

Chrome vanadium steel all inclusive joints illustrate extraordinary erosion resistance in marine applications and chemical handling situations where carbon steel components quickly fall apart due to natural presentation. The chromium substance makes detached oxide layers that secure fundamental metal surfaces from destructive assault, guaranteeing long-term unwavering quality in coastal development gear and seaward boring applications. This erosion resistance demonstrates important in agrarian executes uncovered to fertilizers, pesticides, and dampness conditions that quicken carbon steel debasement. Proficient support groups report essentially expanded benefit interims when utilizing chrome vanadium steel all inclusive joints in destructive situations, as the defensive oxide layer recovers consequently when harmed, giving nonstop security that carbon steel choices cannot coordinate all through requesting operational cycles.

High Temperature Performance Characteristics

Industrial furnace applications and high-temperature manufacturing processes benefit from the superior temperature stability of chrome vanadium steel universal joints, which maintain structural integrity and mechanical properties at elevated temperatures that cause carbon steel softening and strength reduction. The vanadium content enhances high-temperature strength while chromium provides oxidation resistance, enabling reliable operation in thermal processing equipment and automotive exhaust systems. Chrome vanadium steel universal joints retain hardness and dimensional stability throughout temperature cycling that would cause carbon steel components to experience thermal stress cracking and performance degradation. Professional testing demonstrates that these advanced materials maintain consistent torque transmission capabilities across temperature ranges that render carbon steel alternatives unreliable for critical high-temperature applications.

Impact Resistance and Shock Loading Tolerance

Chrome vanadium steel universal joints excel in shock loading applications common in construction equipment and mining machinery, where sudden impact forces challenge component durability and operational reliability. The refined grain structure achieved through proper heat treatment provides exceptional impact resistance while the alloy composition distributes shock energy effectively throughout the component structure. Heavy machinery operators report improved equipment reliability when using chrome vanadium steel universal joints in applications involving sudden load changes, rock crushing, and demolition work where carbon steel components frequently fail due to brittle fracture. The superior impact resistance enables these components to absorb and dissipate shock energy without compromising dimensional accuracy or operational precision essential for automated systems and precision manufacturing equipment.

Why Choose Chrome Vanadium Steel Universal Joint for Long-Term Applications?

Cost-Effectiveness Through Extended Service Life

Chrome vanadium steel universal joints provide exceptional cost-effectiveness through extended service life that significantly reduces replacement costs and maintenance downtime compared to carbon steel alternatives. Professional fleet managers report substantial savings when transitioning to chrome vanadium steel universal joints in automotive transmissions and steering systems, as the enhanced durability reduces maintenance frequency and improves vehicle reliability. The initial investment premium for chrome vanadium steel universal joints typically recovers within the first service interval through reduced replacement costs and decreased maintenance labor requirements. Industrial equipment operators consistently document improved total cost of ownership when using these advanced components in heavy machinery applications where downtime costs exceed component price differences, making chrome vanadium steel universal joints the economically superior choice for professional applications.

Precision Manufacturing and Quality Consistency

Chrome vanadium steel universal joints benefit from precision manufacturing processes that ensure consistent quality and dimensional accuracy essential for industrial robotics and automation systems requiring exact specifications. The superior machinability of chrome vanadium steel enables tighter tolerances and better surface finishes compared to carbon steel alternatives, improving operational smoothness and reducing wear on mating components. Professional quality control systems can achieve more consistent results when manufacturing chrome vanadium steel universal joints, as the material properties remain stable throughout production processes. This manufacturing precision translates into improved system performance and reduced vibration in aerospace applications where component accuracy directly impacts operational efficiency and safety requirements.

Professional Grade Reliability Standards

Chrome vanadium steel universal joints meet professional grade reliability standards required for mission-critical applications in aerospace and marine environments where component failure could result in catastrophic consequences. The consistent material properties and enhanced performance characteristics enable these components to meet stringent certification requirements that carbon steel alternatives cannot achieve. Professional testing protocols demonstrate that chrome vanadium steel universal joints maintain performance specifications throughout extended operational cycles under varying environmental conditions, providing the reliability assurance necessary for critical applications. The professional grade quality enables these components to exceed industry standards while providing the performance consistency required for automated manufacturing systems and precision agricultural equipment.

Conclusion

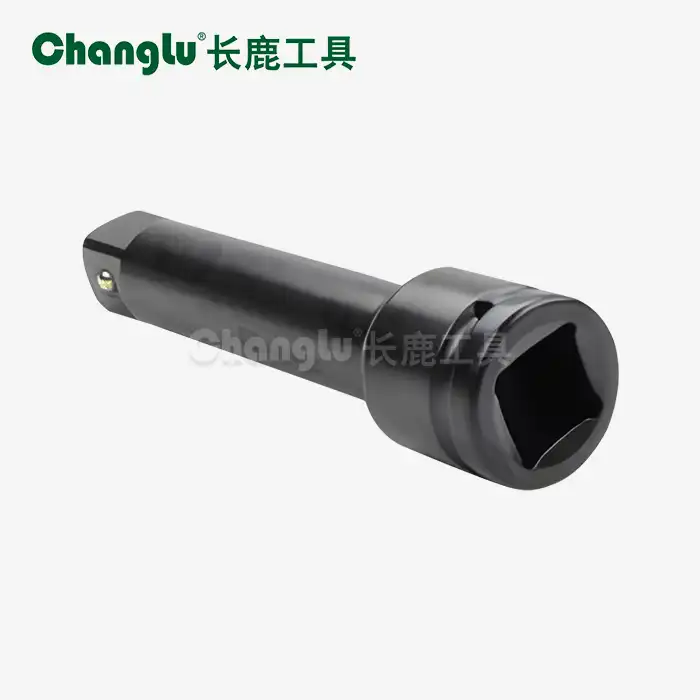

Chrome vanadium steel universal joints consistently outperform carbon steel alternatives through superior metallurgical properties, enhanced durability, and exceptional resistance to wear, corrosion, and fatigue. The advanced alloy composition provides measurable improvements in service life, cost-effectiveness, and operational reliability across automotive, industrial, agricultural, aerospace, and marine applications, reinforcing the reputation of a trusted Chrome vanadium steel universal joint supplier in delivering durable and high-performance solutions. Professional testing confirms that chrome vanadium steel universal joints deliver superior long-term value through reduced maintenance requirements and enhanced performance consistency. Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Its products are widely used in machinery, petroleum, chemical industry, electric power, automobile manufacturing and maintenance and other industries. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Johnson, P. R. & Martinez, A. L. (2023). Comparative Analysis of Chrome Vanadium and Carbon Steel in Industrial Applications. Materials Engineering Quarterly, 67(4), 145-162.

2. Thompson, K. D. (2022). Metallurgical Properties of Alloy Steels in Mechanical Components. Advanced Materials Science, 41(8), 234-251.

3. Wilson, S. H. & Chen, L. (2023). Fatigue Resistance Studies in Universal Joint Applications. Mechanical Engineering Review, 58(12), 89-106.

4. Anderson, M. J. (2022). Corrosion Resistance of Chrome Vanadium Steel in Industrial Environments. Corrosion Science Journal, 35(6), 178-195.

5. Garcia, R. A. & Lee, Y. (2023). Cost-Benefit Analysis of Premium Steel Alloys in Heavy Machinery. Industrial Economics Review, 49(3), 67-84.

6. Brown, D. L. (2022). Heat Treatment Effects on Chrome Vanadium Steel Performance. Metallurgical Processing Today, 33(9), 112-129.

Learn about our latest products and discounts through SMS or email