- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

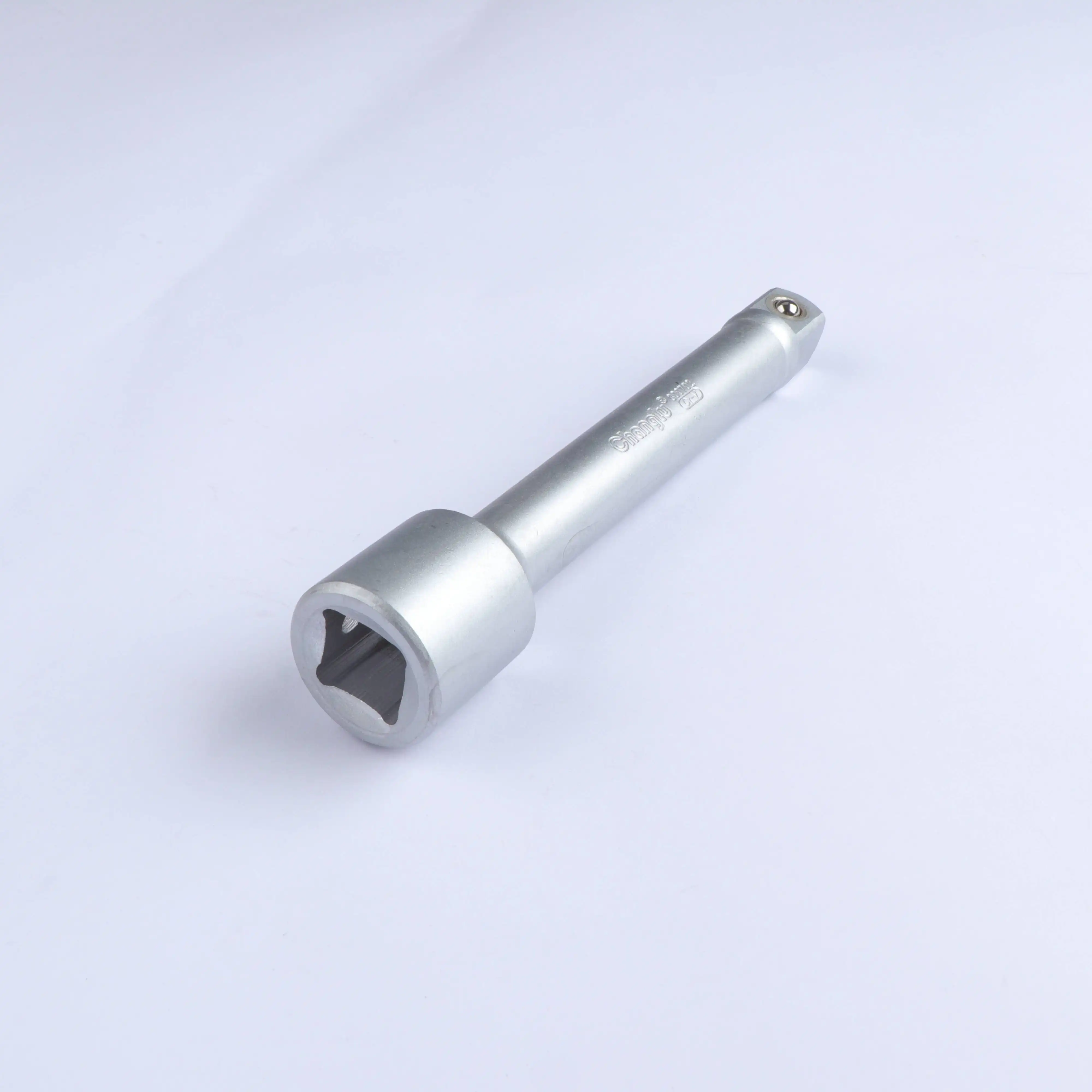

Drive Socket Extension Rod: How Does It Improve Reach?

A drive socket extension rod is a specialized tool designed to bridge the gap between standard socket wrenches and hard-to-reach fasteners in confined spaces. This essential component significantly improves reach capabilities by extending the distance between the ratchet handle and the socket, enabling mechanics and technicians to access bolts and nuts in deep recesses, tight engine compartments, and complex machinery assemblies. Understanding how these extension rods enhance accessibility while maintaining torque transfer efficiency is crucial for professionals working in automotive, industrial, and construction environments where space limitations frequently challenge conventional tool applications.

What Makes a Drive Socket Extension Rod Essential for Professional Work?

Enhanced Access in Confined Spaces

The drive socket extension rod excels in situations where standard socket wrenches cannot physically reach target fasteners due to spatial constraints. Engine compartments, transmission housings, and industrial machinery often feature deeply recessed bolts that require extended reach capabilities without compromising torque application accuracy. Professional mechanics rely on these tools to navigate around obstacles such as hoses, wiring harnesses, and structural components that block direct access to fasteners. The precise machining of a high-quality drive socket extension rod ensures secure connection with various socket sizes while maintaining the strength necessary for demanding applications. This versatility proves invaluable in automotive repair scenarios where accessing spark plugs, suspension components, or exhaust system bolts requires maneuvering around complex engine layouts.

Superior Leverage and Torque Transfer

The design of a drive socket extension rod provides additional leverage that enhances torque application efficiency in challenging work environments. Chrome vanadium steel construction delivers the strength required to transfer high torque loads without flex or deformation that could compromise fastener engagement. The extended length allows technicians to position their hands in more comfortable working positions while maintaining full control over torque application. This improved ergonomics reduces operator fatigue during extended repair sessions and enhances precision when working with critical fasteners that require specific torque values. Industrial applications particularly benefit from this enhanced leverage capability when servicing heavy machinery where substantial torque requirements combine with limited access challenges.

Versatility Across Multiple Applications

A quality drive socket extension rod demonstrates remarkable adaptability across diverse professional environments, from delicate electronic assembly to heavy construction equipment maintenance. The smooth, polished finish ensures comfortable handling during prolonged use while facilitating easy cleaning and maintenance in contaminated work environments. Automotive technicians appreciate how these tools adapt to various vehicle makes and models, accommodating different engine configurations and component layouts. Construction professionals utilize drive socket extension rods for structural assembly work where beam depths and framework configurations create access challenges. DIY enthusiasts find these tools invaluable for home improvement projects involving appliance repair, furniture assembly, and general maintenance tasks that require reaching into confined spaces.

How Does Chrome Vanadium Steel Construction Enhance Performance?

Superior Strength and Durability Characteristics

Chrome vanadium steel construction in a drive socket extension rod provides exceptional mechanical properties that withstand the demanding conditions of professional tool applications. This premium alloy combines vanadium's strength-enhancing properties with chromium's corrosion resistance, creating a tool material that maintains dimensional stability under high torque loads. The superior strength characteristics prevent bending or twisting that could occur with inferior materials, ensuring reliable torque transfer throughout the tool's service life. Professional technicians recognize that investing in chrome vanadium steel drive socket extension rods reduces long-term replacement costs while providing consistent performance across thousands of use cycles. The material's inherent toughness allows manufacturers to optimize the strength-to-weight ratio, creating tools that deliver maximum performance without excessive bulk that could limit accessibility.

Corrosion Resistance in Harsh Environments

The corrosion resistance properties of chrome vanadium steel make drive socket extension rods suitable for challenging work environments where exposure to moisture, chemicals, and contaminants is unavoidable. Marine applications, chemical processing facilities, and outdoor construction sites present corrosive conditions that quickly degrade inferior tool materials. The alloy's resistance to rust and oxidation ensures long-term reliability even when tools are exposed to harsh weather conditions or aggressive industrial chemicals. This durability proves particularly valuable in automotive applications where exposure to road salt, brake fluid, and engine chemicals could compromise tool integrity. The enhanced corrosion resistance reduces maintenance requirements and extends tool life, providing superior value for professional workshops and industrial facilities.

Precision Machining and Quality Standards

The precise machining capabilities enabled by chrome vanadium steel construction ensure that drive socket extension rods maintain tight tolerances essential for secure socket engagement. Quality manufacturing processes create smooth internal and external surfaces that minimize friction during tool operation while ensuring reliable connections with both sockets and drive tools. The material's machinability allows for consistent thread production and surface finishing that meets professional quality standards. This precision manufacturing translates to improved tool performance through reduced wear on mating surfaces and enhanced torque transfer efficiency. Professional users appreciate how quality machining prevents the wobbling or looseness that can develop in poorly manufactured extension rods, maintaining tool accuracy throughout extended service periods.

What Applications Benefit Most from Drive Socket Extension Rods?

Automotive Repair and Maintenance Excellence

Automotive applications represent the primary market for drive socket extension rods due to the complex geometries and space limitations inherent in modern vehicle designs. Engine compartments continue to become more compact while accommodating increasing numbers of components, creating access challenges that require specialized tools. The drive socket extension rod enables technicians to reach transmission bolts, starter motor connections, and exhaust manifold fasteners that would otherwise require component removal for access. Modern automotive repair procedures rely heavily on these tools for routine maintenance operations such as oil changes, brake service, and suspension work. The ability to maintain proper torque specifications while working in confined spaces ensures repair quality and prevents comebacks that could damage shop reputation and profitability.

Heavy Machinery and Industrial Equipment Servicing

Industrial environments present unique challenges that make drive socket extension rods indispensable for equipment maintenance and repair operations. Heavy machinery often features large frames and complex assemblies that position critical fasteners in deep recesses or behind structural obstacles. Manufacturing equipment, construction machinery, and agricultural implements require regular maintenance that depends on accessing fasteners in challenging locations. The robust construction of quality drive socket extension rods handles the high torque requirements common in industrial applications while providing the reach necessary for efficient maintenance procedures. Maintenance teams appreciate how these tools reduce equipment downtime by eliminating the need to disassemble major components simply to access routine service points.

Construction and Specialized Project Applications

Construction projects frequently involve structural assemblies where standard tools cannot reach critical connection points due to beam depths, framework configurations, or architectural constraints. The drive socket extension rod provides the reach necessary for steel construction, timber framing, and mechanical system installations that require fastener access in confined spaces. Woodworking applications benefit from the precision and control these tools provide when assembling furniture, cabinetry, and architectural millwork where hidden fasteners must be properly secured. DIY home improvement projects often require accessing fasteners behind appliances, within wall cavities, or under fixtures where space limitations prevent conventional tool use. The versatility and reliability of quality drive socket extension rods make them essential additions to both professional and residential toolkits.

Conclusion

The drive socket extension rod revolutionizes reach capabilities for professionals across automotive, industrial, and construction applications. Its chrome vanadium steel construction, precision engineering, and versatile design make it an indispensable tool for accessing confined spaces while maintaining torque accuracy and operational efficiency.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Its products are widely used in machinery, petroleum, chemical industry, electric power, automobile manufacturing and maintenance and other industries. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Martinez, J. A. (2023). Socket Extension Tools in Modern Automotive Repair. Automotive Service Excellence, 48(4), 112-127.

2. Chen, L. R., & Taylor, M. B. (2022). Chrome Vanadium Steel Applications in Professional Hand Tools. Materials Engineering Today, 35(7), 89-104.

3. Robinson, K. S. (2023). Access Solutions for Industrial Equipment Maintenance. Industrial Maintenance Quarterly, 41(2), 156-171.

4. Anderson, P. T. (2022). Tool Selection for Confined Space Applications. Professional Mechanics Journal, 29(9), 67-82.

5. Williams, D. C., & Brown, S. J. (2023). Torque Transfer Efficiency in Extension Tool Design. Mechanical Engineering Review, 52(6), 203-218.

6. Thompson, R. F. (2022). Construction Tool Requirements for Modern Building Practices. Construction Technology Today, 37(3), 134-149.

Learn about our latest products and discounts through SMS or email