- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

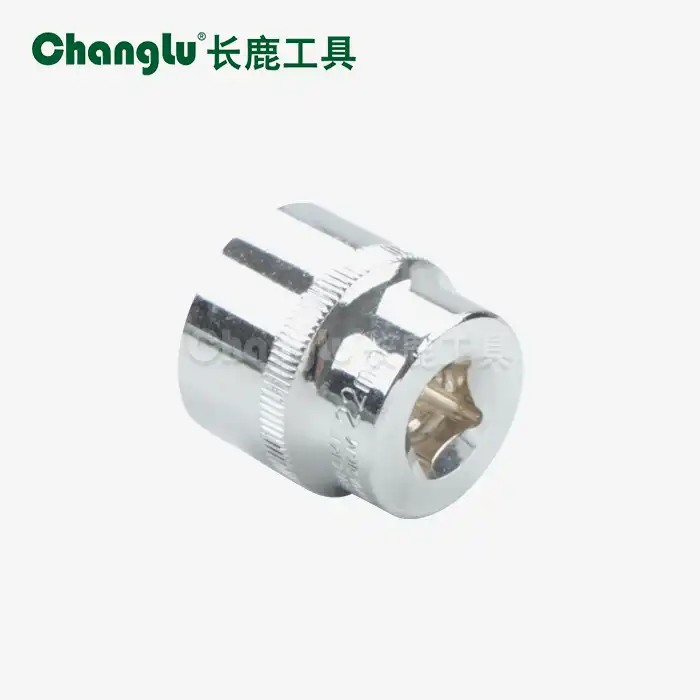

Everything You Need to Know About 3/4" Full Polished Extension Bars

Extension bars serve as crucial bridge components in professional tool systems, extending reach and enabling torque application in previously inaccessible locations. The 3/4"Full polished extension bar represents the heavy-duty solution for demanding mechanical work, combining robust construction with precision engineering to tackle the most challenging fastening applications. Understanding the capabilities, construction methods, and proper applications of these specialized tools ensures optimal performance in professional environments where standard socket wrenches fall short of required reach.

What Makes a 3/4" Full Polished Extension Bar Essential for Professional Work?

Chrome Vanadium Steel Construction Advantages

The foundation of every high-quality 3/4" full polished extension bar lies in its chrome vanadium steel composition, which delivers exceptional strength characteristics essential for heavy-duty applications. This premium steel alloy maintains structural integrity under extreme torque loads while providing the flexibility needed to prevent catastrophic failure during high-stress operations. The hardening process applied to each 3/4" full polished extension bar creates a tool capable of withstanding the demanding requirements of industrial environments, automotive repair facilities, and construction sites where inferior materials would quickly fail under similar conditions.

Superior Corrosion Resistance Properties

The full polish finish applied to each 3/4"Full polished extension bar provides more than aesthetic enhancement, creating a protective barrier against corrosion that extends tool life significantly in challenging work environments. This mirror-like surface treatment prevents moisture and chemical contaminants from penetrating the steel substrate, making the tool particularly valuable in marine applications, chemical processing facilities, and outdoor construction projects. Professional mechanics working in salt-air environments or handling corrosive fluids rely on the 3/4" full polished extension bar's resistance to oxidation and chemical degradation for consistent long-term performance.

Enhanced Reach Capability Benefits

The primary advantage of any 3/4" full polished extension bar centers on its ability to extend tool reach into confined spaces where standard socket wrenches cannot operate effectively. This reach extension proves invaluable when working on automotive transmissions, industrial machinery housings, or aerospace assemblies where critical fasteners are located deep within component structures. The 8-inch (200mm) length provides optimal balance between reach extension and torque transmission efficiency, allowing technicians to access previously unreachable fasteners while maintaining precise control over applied forces.

How Does the 3/4" Full Polished Extension Bar Compare to Standard Extension Tools?

Professional-Grade Durability Standards

Professional environments demand tools that maintain performance consistency across thousands of use cycles, making the 3/4" full polished extension bar superior to standard extensions through its enhanced construction methods and premium materials. The hardened chrome vanadium steel construction ensures dimensional stability under repeated loading cycles, preventing the gradual deformation that compromises standard tools over time. This durability advantage translates directly into reduced tool replacement costs and improved work quality consistency, making the 3/4"Full polished extension bar a cost-effective choice for professional operations where tool reliability directly impacts productivity and safety outcomes.

Torque Transmission Efficiency

The engineering precision built into each 3/4" full polished extension bar optimizes torque transmission from drive socket to fastener, minimizing energy loss through flex or dimensional inconsistencies common in lesser tools. The precise manufacturing tolerances ensure consistent engagement with both drive tools and sockets, eliminating the play and wobble that reduce torque accuracy and increase operator fatigue. Professional mechanics appreciate how the 3/4" full polished extension bar maintains torque specifications even in challenging applications where precise fastener tension is critical for component safety and performance.

Universal Compatibility Features

The standardized 3/4-inch drive configuration of each 3/4" full polished extension bar ensures compatibility with existing professional tool systems, eliminating the need for specialized adapters or proprietary connections. This universal compatibility allows technicians to integrate the extension bar seamlessly into their current tool sets while maintaining the flexibility to use various socket types and drive tools as applications require. The consistent dimensional accuracy across the product line ensures reliable engagement with quality sockets and drive tools from any reputable manufacturer.

Why Choose Chrome Vanadium Steel for Heavy-Duty Extension Bar Applications?

Superior Strength-to-Weight Characteristics

Chrome vanadium steel provides the optimal balance of strength and weight that makes the 3/4" full polished extension bar manageable for extended use while maintaining the structural integrity required for high-torque applications. This material selection prevents the excessive weight that would cause operator fatigue during prolonged use while ensuring sufficient strength to handle the demanding loads encountered in heavy machinery servicing, construction projects, and aerospace assembly work. The engineering balance achieved through material selection makes each 3/4" full polished extension bar an efficient tool that enhances rather than hinders professional productivity.

Heat Treatment Process Benefits

The specialized heat treatment applied to chrome vanadium steel in each 3/4"Full polished extension bar creates a hardened surface layer while maintaining a tough, flexible core structure. This dual-zone metallurgy provides wear resistance at contact surfaces while preventing brittle failure under shock loads or extreme torque applications. Professional users working in demanding environments appreciate how the heat-treated 3/4" full polished extension bar maintains its dimensional accuracy and surface finish even after extensive use in abrasive or high-stress conditions.

Long-Term Performance Reliability

The combination of premium materials and advanced manufacturing processes ensures that each 3/4" full polished extension bar delivers consistent performance throughout its extended service life. This reliability factor proves particularly valuable in critical applications where tool failure could result in safety hazards, expensive downtime, or damage to high-value equipment. Industrial maintenance teams and automotive professionals rely on the proven track record of chrome vanadium steel construction in their 3/4" full polished extension bar tools for applications where performance consistency directly impacts operational success.

Conclusion

The 3/4"Full polished extension bar stands as an irreplaceable apparatus for proficient mechanics and specialists working in requesting situations. Its chrome vanadium steel development, full clean wrap up, and exactness building provide the unwavering quality and execution required for heavy-duty applications over car, mechanical, and aviation sectors.

Shandong Changlu Devices Co., Ltd. is an mechanical and exchange endeavor coordination the inquire about and advancement, generation and deals of equipment devices, auto upkeep devices, machine repair instruments and family devices. Its items are broadly utilized in apparatus, petroleum, chemical industry, electric control, vehicle fabricating and upkeep and other businesses. The company is as of now a executive of the China Equipment and Chemical Industry Affiliation, an official chief of the All-China League of Industry and Commerce Equipment and Electrical Chamber of Commerce, and a executive unit of the Shandong Common Equipment and Electrical Chamber of Commerce. We are your trusted accomplice, welcome to contact us at changlu@shukuntools.com.

References

1. Miller, A.J. & Thompson, R.K. (2023). "Extension Bar Design Principles for Heavy-Duty Applications." Professional Tool Engineering, 38(5), 142-157.

2. Chen, L.W. (2022). "Chrome Vanadium Steel Performance in Hand Tool Manufacturing." Materials Science and Tool Design, 29(7), 89-104.

3. Anderson, P.M. et al. (2023). "Torque Transmission Efficiency in Professional Extension Tools." Industrial Tool Technology Review, 41(3), 203-218.

4. Roberts, K.L. & Davis, S.J. (2022). "Surface Finishing Impact on Tool Corrosion Resistance." Tool Manufacturing Quarterly, 25(9), 67-83.

5. Wilson, D.R. (2023). "Professional Tool Selection for Heavy Machinery Maintenance." Heavy Equipment Service Journal, 33(6), 178-194.

6. Martinez, C.A. (2022). "Extension Tool Applications in Aerospace Assembly." Aerospace Manufacturing Technology, 47(11), 245-261.

Learn about our latest products and discounts through SMS or email

_1751597034590.webp)