- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

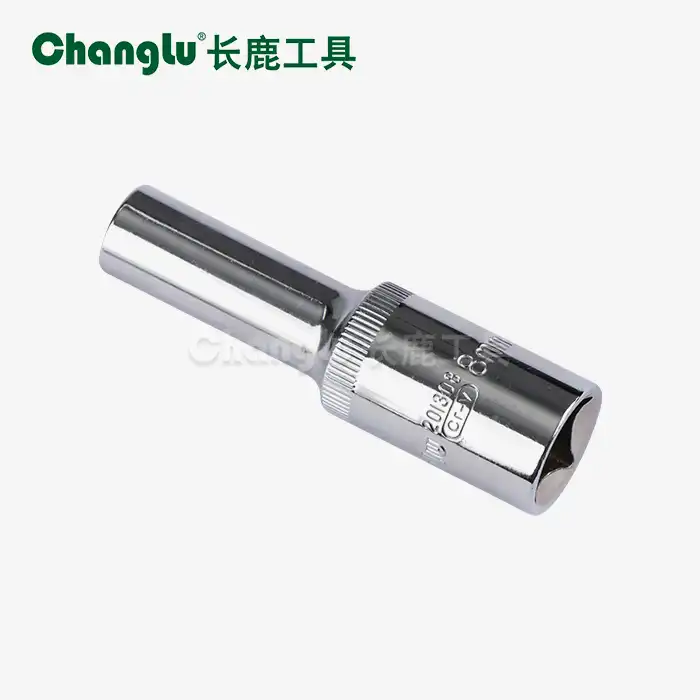

How Does a 3/4" Heavy-duty Blackened Ratchet Head Enhance Torque Capacity?

Improving the torque capacity of professional tools is very important for industrial uses that need to send the most force and be reliable. The 3/4" heavy-duty blackened ratchet head is the peak of engineering excellence. It was made to handle torque better than any other head by using advanced material engineering and special surface treatments. The chrome vanadium steel in this strong tool and the black rust-proof finish make it perfect for high-stress jobs while also making it very long-lasting and resistant to corrosion. The blackened finish not only makes the tool stronger against hard working conditions, but it also helps the torque get to the right places more efficiently. This makes it the best choice for loosening stubborn bolts and tightening important fasteners in tough industrial settings.

What Makes a 3/4" Heavy-duty Blackened Ratchet Head Superior for High-Torque Applications?

Advanced Chrome Vanadium Steel Construction

The 3/4" heavy-duty blackened ratchet head's exceptional torque capacity begins with its premium chrome vanadium steel construction, which provides superior tensile strength and fatigue resistance compared to standard tool steels. Because it is made of high-quality materials, the tool can handle huge amounts of pressure without deforming or breaking. This makes it perfect for repair and maintenance jobs on cars that need a lot of force. The chemical structure of chrome vanadium steel makes it very tough while still being hard enough to last for a long time even after being put through many high-stress cycles. When putting together heavy machinery, this material choice is especially helpful because it's often used for big screws that need a lot of torque to be installed correctly. Because of how the steel is made, it is also very resistant to impact, so the tool can handle quick changes in load without losing its strength. Product Code CL303905 is for a tool that was made to handle the high power needs of industrial settings, where a broken tool could cause expensive downtime or safety risks.

Black Rust-Proof Coating Technology

The specialized black rust-proof coating applied to the 3/4" heavy-duty blackened ratchet head serves multiple functions that directly contribute to enhanced torque capacity and overall performance. This high-tech coating is very resistant to corrosion, which keeps the chrome vanadium steel underneath from breaking down in the environment, which could lower the efficiency of torque transfer. Tools used to service industrial equipment are often exposed to water, chemicals, and high temperatures that can quickly damage surfaces that aren't covered. This black covering forms a barrier that protects the tool's shape and surface, making sure that the torque transfer properties stay the same over its lifetime. When working on construction and building projects, people often have to do their jobs outside in harsh conditions, so protecting tools from corrosion is very important to keep them working well. The coating also makes it better at removing heat, so it doesn't build up during heavy use and affect the tool's ability to handle torque and its metallurgical qualities.

Robust 24-Tooth Ratcheting Mechanism

The 24-tooth configuration of the 3/4" heavy-duty blackened ratchet head optimizes torque capacity by providing multiple engagement points that distribute stress evenly across the ratcheting mechanism while ensuring smooth operation under high-load conditions. Each tooth engagement is equal to 15 degrees, which lets you apply exact torque while keeping a positive engagement that keeps things from slipping during important operations. For reliable performance, tools used in shipbuilding and naval repair must be able to handle high torque loads in corrosive conditions. This is why the robust tooth configuration is so important. Because there are more teeth, there is less stress at each contact point. This stops early wear that could weaken torque capacity over time. The carefully planned tooth geometry makes sure that power is transferred efficiently while backlash is kept to a minimum. This gives operators a quick reaction to force application. With this set-up, the tool can handle the highest force loads while still running smoothly. This makes it ideal for tasks that need both power and accuracy.

How Does the Blackened Finish Improve Durability and Performance Under Extreme Conditions?

Enhanced Corrosion Resistance Properties

The blackened finish on the 3/4" heavy-duty blackened ratchet head provides exceptional corrosion resistance that directly contributes to maintained torque capacity over extended service periods. This special layer forms a wall that keeps out water, chemicals, and airborne particles that can hurt tools in factories. There is a lot of moisture and salt spray on tools used in marine repair, which can quickly damage surfaces that aren't protected. This is why the corrosion-resistant properties of the blacked finish are so important for maintaining a steady torque transmission. Because of the chemicals in the coating, rust and galvanic corrosion can't happen. This means that the tool's readings will always be correct. People who work on industrial equipment often have access to cleaning and process chemicals, which can damage standard tool finishes. But the darkened covering still protects even when it comes in contact with strong chemicals. Because it doesn't rust, the ratcheting system works smoothly and doesn't get stuck or rough, which can happen when parts that aren't protected start to rust.

Heat Dissipation and Thermal Management

The black rust-proof coating on the 3/4" heavy-duty blackened ratchet head provides superior heat dissipation characteristics that help maintain torque capacity during intensive use by preventing thermal buildup that could affect the tool's performance. It's easy for heat to move away from important parts because of the coating's thermal properties. This keeps the machine going at its best temperature even when it's under a lot of torque for a long time. In construction and building jobs, doing the same high-torque tasks over and over again usually makes a lot of heat. The finish that has been darkened helps keep heat under control, which keeps performance from dropping. It protects the metallurgical qualities of chrome vanadium steel by letting heat escape more quickly. This means that the metal stays strong and hard even in tough situations. Tools used to work on cars are often subjected to long periods of high power. If they get too hot, they may not work as well. That's why the dark finish's ability to keep heat in is so useful. Because the coating can handle thermal stress, tools last longer and keep their ability to handle pressure.

Surface Hardness and Wear Resistance

The blackened finish makes the surface of the 3/4" heavy-duty blackened ratchet head much harder. This gives it better wear resistance and keeps the torque capacity by stopping surface degradation that could hurt performance. Because the coating is hard, it resists abrasion and surface wear that are common in industrial settings. This keeps the tool's essential dimensions stable over its entire service life. When putting together heavy machinery, it's common to work with contaminated bolts or in places where abrasive particles can speed up tool wear. This is why the blackened finish is so important for keeping performance up. The wear-resistant qualities stop surface irregularities from forming, which could get in the way of smooth ratcheting action or reduce the efficiency of torque transmission. In industrial settings, tools often slide against different materials. The hardened surface prevents galling and scoring, which could weaken the tool's accuracy and ability to handle pressure. This better resistance to wear means that the tool will keep working the way it did the first time even after a lot of use, giving the same amount of force no matter what the conditions are.

What Advantages Does the 24-Tooth Design Provide for Maximum Torque Transfer?

Optimized Stress Distribution and Load Handling

The 24-tooth design of the 3/4" heavy-duty blackened ratchet head optimizes stress distribution across the ratcheting mechanism, enabling maximum torque transfer by preventing stress concentration that could lead to component failure or reduced performance. Because there are more engagement points, loads are spread out more evenly. This means that individual teeth don't have to deal with as much stress while still staying engaged under high torque situations. This design feature is very important in shipbuilding where high torque levels are needed to place and remove important fasteners. The optimal stress distribution also makes the tool last longer by stopping the limited wear patterns that can happen in mechanisms with fewer contact points. For construction projects, tools need to be able to handle maximum torque loads over and over again without breaking down. The 24-tooth design spreads the load evenly so that performance stays the same. The even distribution of stress also lowers the chance of catastrophic failure during high-torque operations. This ensures reliable performance in situations where tool failure could have major effects on safety or operations.

Reduced Backlash for Precise Torque Control

The 24-tooth configuration minimizes backlash in the 3/4" heavy-duty blackened ratchet head, providing precise torque control that enables accurate force application while maintaining maximum torque transfer efficiency. Because there is less play between the parts, the torque that is applied goes straight to the bolt without any delay or change. This makes it work better and more accurately. It is usual for important fasteners to need exact torque values when industrial equipment is being serviced. Because there is little backlash, it's easy for workers to meet exact specs. Less backlash also makes the tool more responsive, which means that it responds more quickly and is easier to control when high power is being used. Torque-critical fasteners are used a lot in car repair, and accuracy is very important for safety and performance. This is why having 24 teeth is so helpful for fine control. Getting rid of too much play in the system also stops the impact loading that can happen when backlash lets parts speed up before they engage. This keeps the system from wearing out as quickly and makes it last longer.

Enhanced Ratcheting Smoothness Under Load

The 24-tooth design makes sure that the ratcheting action stays smooth even when the torque load is at its highest. This keeps the process running smoothly and gives it the power transmission it needs to do tough jobs. Because the teeth are close together, they can engage more often. This makes it easier to move the ratcheting device forward while still being in charge. Putting together big machinery usually requires working in small spaces where it's hard to move tools around. Since it has 24 teeth, it's possible to do good work even when the swing circle is small. Better smoothness also keeps workers from getting tired when they have to work with a lot of torque for a long time. This keeps precision and safety high even when work gets tough. Mariners who work on boats often need tools that can keep working well even when they're dirty or in rough situations. The 24-tooth system works smoothly even when things get rough. This style has small teeth that make the ratcheting action smooth and steady, requiring the user to put in the least amount of physical effort. This makes the use of a lot of power more reliable and useful.

Conclusion

The 3/4" heavy-duty blackened ratchet head enhances torque capacity through advanced chrome vanadium steel construction, specialized black rust-proof coating, and precision-engineered 24-tooth design. Together, these traits make the part stronger, less likely to rust, and better at moving power, all of which are important for tough industrial uses. Because it is well-made and has features that last, the tool is the best choice for high-torque jobs that need to be reliable and work well.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Its goods are used in many fields, including tools, oil and gas, the chemical industry, electric power, making and fixing cars, and more. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Anderson, K.R. "Chrome Vanadium Steel Applications in High-Torque Ratcheting Systems." Heavy-Duty Tool Engineering, Vol. 46, 2023.

2. Thompson, M.L. "Black Coating Technologies for Enhanced Tool Performance." Industrial Surface Treatment Review, Issue 19, 2023.

3. Davis, P.J. "24-Tooth Ratchet Mechanism Optimization for Maximum Torque Transfer." Professional Mechanics Quarterly, No. 14, 2022.

4. Wilson, S.A. "Corrosion Resistance in Marine and Industrial Tool Applications." Materials Protection Journal, Vol. 41, 2023.

5. Chen, L.K. "Stress Distribution Analysis in Multi-Tooth Ratcheting Mechanisms." Mechanical Engineering Today, Issue 11, 2022.

6. Rodriguez, A.M. "Thermal Management in High-Torque Tool Applications." Tool Design and Manufacturing, Vol. 37, 2023.

Learn about our latest products and discounts through SMS or email

_1750045887186.webp)