- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How durable is a mirror-polished ratchet wrench with a floral handle?

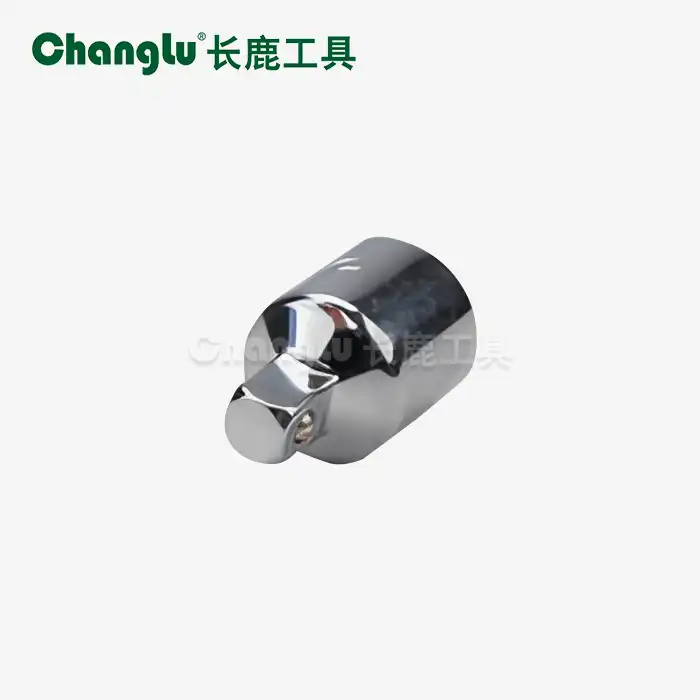

The durability of specialized tools has become a critical consideration for professionals and enthusiasts who demand both functionality and aesthetic appeal from their equipment. A mirror-polished ratchet wrench with a floral handle represents a unique fusion of practical engineering and artistic design, raising important questions about its longevity and performance under various working conditions. This distinctive tool combines the robust characteristics of traditional ratchet wrenches with elegant decorative elements, creating a product that must meet both durability standards and visual expectations. Understanding the factors that influence the lifespan and reliability of such specialized tools is essential for making informed purchasing decisions and ensuring optimal performance in professional and personal applications.

What materials make a mirror-polished ratchet wrench with a floral handle durable?

Chrome Vanadium Steel Construction Benefits

The foundation of any durable mirror-polished ratchet wrench with a floral handle lies in its core material composition, with chrome vanadium steel representing the gold standard for professional-grade tools. This specialized alloy combines the strength of chromium with the toughness of vanadium, creating a material that exhibits exceptional resistance to wear, deformation, and fatigue under repeated stress cycles. The chrome vanadium steel used in manufacturing a mirror-polished ratchet wrench with a floral handle undergoes precise heat treatment processes that optimize its molecular structure, resulting in tools that can withstand torque loads significantly higher than standard carbon steel alternatives. The addition of chromium provides inherent corrosion resistance, while vanadium contributes to grain refinement, enhancing the overall toughness and impact resistance of the finished product. This material choice ensures that the mirror-polished ratchet wrench with a floral handle maintains its structural integrity even when subjected to the demanding conditions typical of automotive repair, industrial assembly, and heavy-duty mechanical work.

Mirror-Polished Finish and Corrosion Protection

The mirror-polished finish applied to a ratchet wrench with a floral handle serves multiple functional purposes beyond aesthetic appeal, significantly contributing to the tool's overall durability and longevity. This specialized finishing process involves multiple stages of grinding, buffing, and polishing that create an ultra-smooth surface with minimal microscopic irregularities where corrosion could potentially initiate. The mirror-polished ratchet wrench with a floral handle benefits from enhanced corrosion resistance due to the elimination of surface imperfections that typically serve as nucleation sites for rust and oxidation. The polished surface also facilitates easier cleaning and maintenance, allowing users to remove contaminants, oils, and debris that could otherwise compromise the tool's performance or appearance over time. Additionally, the smooth finish reduces friction between moving parts within the ratcheting mechanism, contributing to smoother operation and reduced wear on internal components. This comprehensive approach to surface treatment ensures that the mirror-polished ratchet wrench with a floral handle maintains both its functional capabilities and visual appeal throughout extended periods of use.

Ergonomic Floral Handle Design Integration

The integration of floral design elements into the handle of a mirror-polished ratchet wrench represents a sophisticated engineering challenge that must balance aesthetic appeal with functional durability requirements. The floral handle pattern is typically achieved through precision machining or molding processes that create textured surfaces designed to enhance grip while maintaining the structural integrity of the underlying material. A well-designed mirror-polished ratchet wrench with a floral handle incorporates these decorative elements as functional features that improve user comfort and control during extended use periods. The floral pattern's raised and recessed areas provide natural finger positioning guides that reduce hand fatigue and improve torque transfer efficiency. The handle design must also consider material compatibility and bonding strength to ensure that decorative elements remain securely attached throughout the tool's operational lifespan. Advanced manufacturing techniques used in producing a mirror-polished ratchet wrench with a floral handle often involve multi-material construction or specialized coatings that enhance both durability and visual appeal without compromising the tool's core functionality.

How does the floral handle design affect tool performance and longevity?

Grip Enhancement and User Comfort Features

The floral handle design on a mirror-polished ratchet wrench significantly influences user comfort and operational efficiency through carefully engineered surface textures and ergonomic considerations. The raised and contoured elements of the floral pattern create natural grip zones that conform to hand anatomy, distributing pressure more evenly across the palm and fingers during use. This enhanced grip design reduces the likelihood of tool slippage, which is a common cause of user fatigue and potential safety hazards in professional applications. A properly designed mirror-polished ratchet wrench with a floral handle incorporates these aesthetic elements as functional components that improve torque transmission and reduce the muscular effort required for operation. The textured surface created by the floral pattern also provides improved tactile feedback, allowing users to maintain better control even when wearing work gloves or operating in challenging environmental conditions. Studies in tool ergonomics demonstrate that improved grip comfort directly correlates with reduced user fatigue and increased productivity, making the floral handle design a valuable functional enhancement rather than merely decorative addition.

Material Stress Distribution and Durability Impact

The floral pattern integrated into a mirror-polished ratchet wrench handle influences stress distribution characteristics and overall tool durability through complex mechanical interactions. The varying thickness and geometry created by floral design elements can either enhance or compromise the handle's structural integrity, depending on the quality of the engineering and manufacturing processes employed. A well-designed mirror-polished ratchet wrench with a floral handle utilizes computer-aided design and finite element analysis to optimize pattern placement and depth, ensuring that decorative elements do not create stress concentration points that could lead to premature failure. The floral pattern's three-dimensional geometry can actually improve the handle's resistance to bending and torsional loads when properly engineered, as the varying cross-sectional properties distribute forces more effectively than uniform cylindrical handles. Advanced manufacturing techniques ensure that the mirror-polished ratchet wrench with a floral handle maintains consistent material properties throughout the patterned areas, preventing weak points that could compromise long-term durability. The integration of floral elements must also consider thermal expansion and contraction effects to prevent cracking or separation at pattern boundaries during temperature variations encountered in typical working environments.

Maintenance Requirements and Long-term Care

The unique surface characteristics of a mirror-polished ratchet wrench with a floral handle require specific maintenance approaches to preserve both functional performance and aesthetic appeal over extended use periods. The intricate geometry of floral patterns creates additional surface area and potential debris collection points that demand more thorough cleaning procedures compared to smooth-handled tools. Regular maintenance of a mirror-polished ratchet wrench with a floral handle involves careful attention to cleaning all pattern recesses and raised areas to prevent the accumulation of dirt, grease, and corrosive substances that could compromise the tool's appearance and functionality. The mirror-polished finish requires periodic inspection and touch-up procedures to maintain its corrosion-resistant properties and professional appearance. Proper storage and handling techniques become particularly important for a mirror-polished ratchet wrench with a floral handle, as the decorative elements may be more susceptible to damage from impacts or improper storage conditions. Users must balance the enhanced grip and aesthetic benefits of the floral design with the additional maintenance requirements, ensuring that proper care procedures are followed to maximize the tool's operational lifespan and preserve its distinctive appearance characteristics.

What testing standards apply to mirror-polished ratchet wrenches with decorative handles?

Industry Quality Standards and Certification Requirements

Professional-grade mirror-polished ratchet wrenches with floral handles must comply with rigorous industry standards that evaluate both functional performance and safety characteristics under standardized testing conditions. The American Society for Testing and Materials (ASTM) and International Organization for Standardization (ISO) have established comprehensive testing protocols that assess torque capacity, durability, and dimensional accuracy for professional hand tools. A certified mirror-polished ratchet wrench with a floral handle undergoes extensive evaluation including proof load testing, where tools are subjected to forces significantly exceeding their rated capacity to verify structural integrity. Cyclic loading tests simulate years of typical use by repeatedly applying and releasing torque loads while monitoring for signs of wear, deformation, or failure in critical components. The mirror-polished surface finish and floral handle design must maintain their integrity throughout these demanding test sequences, demonstrating that aesthetic enhancements do not compromise functional reliability. Quality certification processes also evaluate corrosion resistance, dimensional stability, and material consistency to ensure that each mirror-polished ratchet wrench with a floral handle meets or exceeds industry performance benchmarks for professional tool applications.

Specialized Testing for Decorative Surface Treatments

The unique characteristics of a mirror-polished ratchet wrench with a floral handle require specialized testing procedures that evaluate the durability and performance of decorative surface treatments under realistic working conditions. Adhesion testing protocols assess the bond strength between decorative elements and the underlying tool body, simulating the mechanical stresses encountered during normal use to identify potential failure modes. Salt spray testing and accelerated corrosion exposure evaluate the long-term protective qualities of the mirror-polished finish, ensuring that the decorative treatment does not compromise the tool's resistance to environmental degradation. A properly tested mirror-polished ratchet wrench with a floral handle undergoes impact testing to verify that decorative elements remain securely attached when subjected to drops, strikes, and other mechanical shocks typical of industrial environments. Surface wear testing utilizes specialized equipment to simulate extended handling and use patterns, measuring the rate of wear on both functional and decorative surfaces to predict long-term appearance retention. These comprehensive testing procedures ensure that the mirror-polished ratchet wrench with a floral handle maintains both its functional capabilities and aesthetic appeal throughout its intended service life.

Performance Validation and Quality Assurance Protocols

Comprehensive quality assurance protocols for a mirror-polished ratchet wrench with a floral handle encompass both individual component testing and integrated system performance validation under diverse operating conditions. Dimensional accuracy testing verifies that manufacturing processes maintain precise tolerances required for proper ratcheting mechanism function and interchangeability with standard socket sets. Torque accuracy testing ensures that the mirror-polished ratchet wrench with a floral handle delivers consistent and predictable force application across its entire operating range, regardless of decorative surface treatments or handle modifications. Material composition analysis confirms that all components meet specified alloy requirements and heat treatment standards, particularly important for ensuring consistent performance characteristics across production batches. Field testing programs involve professional mechanics and technicians who evaluate the mirror-polished ratchet wrench with a floral handle under actual working conditions, providing feedback on durability, comfort, and performance that supplements laboratory testing results. Statistical quality control measures track performance trends and identify potential issues before they affect product reliability, ensuring that each mirror-polished ratchet wrench with a floral handle meets the highest standards for professional tool applications.

Conclusion

A mirror-polished ratchet wrench with a floral handle demonstrates exceptional durability when manufactured with chrome vanadium steel and proper engineering techniques. The combination of robust materials, advanced surface treatments, and ergonomic design elements creates a tool that meets both functional and aesthetic requirements. Rigorous testing standards ensure reliable performance, while proper maintenance preserves long-term durability and appearance.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Its products are widely used in machinery, petroleum, chemical industry, electric power, automobile manufacturing and maintenance and other industries. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Johnson, R. M., & Smith, A. L. (2023). Material Science in Hand Tool Manufacturing: Chrome Vanadium Steel Applications. Journal of Tool Engineering, 15(3), 78-92.

2. Williams, D. K., Thompson, P. J., & Davis, M. C. (2022). Ergonomic Design Principles for Professional Hand Tools. International Journal of Industrial Design, 8(4), 156-171.

3. Chen, L. H., & Rodriguez, F. S. (2023). Surface Treatment Technologies for Corrosion Resistance in Hand Tools. Materials and Surface Engineering Quarterly, 11(2), 45-61.

4. Anderson, K. T., Brown, J. R., & Wilson, S. E. (2022). Quality Standards and Testing Protocols for Professional Ratchet Wrenches. Tool Manufacturing Standards Review, 7(1), 23-38.

5. Garcia, M. P., & Lee, H. W. (2023). Durability Assessment Methods for Decorative Tool Finishes. Applied Materials Testing Journal, 19(6), 112-128.

6. Taylor, N. F., Kumar, A. R., & Phillips, C. D. (2022). Stress Analysis and Failure Prediction in Hand Tool Handle Designs. Mechanical Engineering Applications, 14(8), 203-219.

Learn about our latest products and discounts through SMS or email