- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Is a Mirror Three Way Wrench Designed?

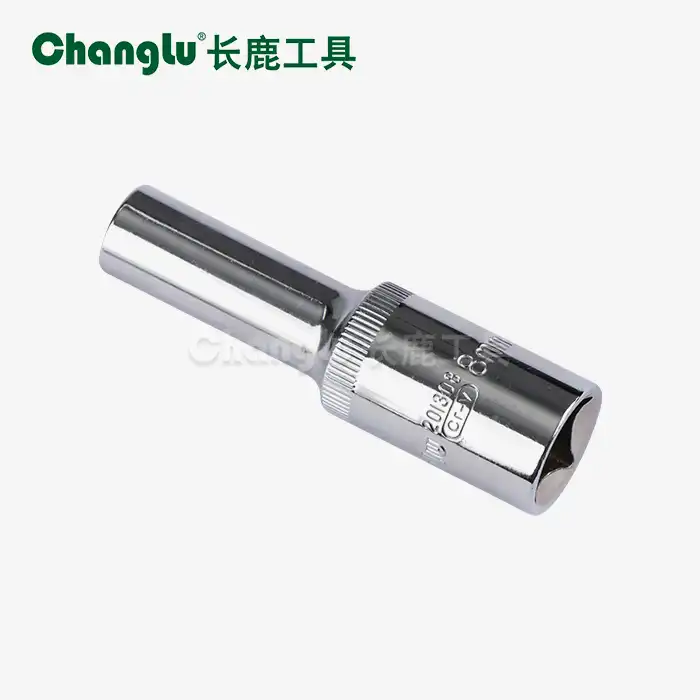

The reflect three-way torque speaks to an imaginative instrument plan that combines numerous attachment arrangements into a single, flexible instrument for proficient and mechanical applications, embodied by the Mirror Three-Way Wrench. This specialized torque highlights a one of a kind three-way attachment course of action with mirror-polished wrapping up, making a apparatus that maximizes proficiency whereas keeping up the solidness and exactness requested by present day fabricating and support operations. Understanding the plan standards behind reflect three way torques is basic for experts looking for flexible affixing arrangements that can handle numerous jolt sizes and arrangements in limited spaces where apparatus changes would be illogical or time-consuming.

What Engineering Principles Define the Mirror Three Way Wrench Construction?

Multi-Socket Integration Technology

The reflect three way torque consolidates modern building that permits three distinctive attachment sizes to be coordinates into a single device body whereas keeping up basic astuteness and torque transmission capabilities. This plan kills the require for numerous partitioned devices, altogether moving forward workflow effectiveness in applications where different clasp sizes must be tended to consecutively. The designing challenge lies in making attachment openings that do not compromise the tool's quality whereas giving secure engagement with distinctive jolt heads. Proficient mechanics and gathering line specialists appreciate how the reflect three way torque diminishes device changes amid complex operations, especially in car gathering where different clasp sizes are commonly utilized inside near vicinity. The integration innovation guarantees that each attachment keeps up legitimate resistances and engagement characteristics in spite of sharing the same device body with other attachment configurations.

Chrome Vanadium Steel Material Selection

The reflect three-way torque utilizes chrome vanadium steel as its essential development fabric, chosen particularly for its extraordinary strength-to-weight proportion and strength characteristics beneath high-stress applications, as seen in the Mirror Three-Way Wrench. This fabric choice guarantees that the device can withstand significant torque loads over all three attachment arrangements without encountering misshapening or disappointment. The chrome vanadium amalgam gives prevalent sturdiness compared to standard carbon steel options, making it perfect for proficient applications where instrument unwavering quality is basic. Fabricating engineers indicate this fabric for reflect three way torques since it keeps up reliable hardness all through the instrument structure, guaranteeing uniform execution over all attachment positions. The material's resistance to wear and weariness makes these instruments reasonable for high-volume generation situations where thousands of securing cycles may happen every day. Quality control testing affirms that chrome vanadium development gives the life span required for proficient apparatus applications.

Mirror Finish Surface Treatment Process

The distinctive mirror finish applied to the three way wrench serves both aesthetic and functional purposes, created through specialized polishing processes that enhance corrosion resistance while providing a professional appearance. This surface treatment involves multiple polishing stages that progressively refine the tool surface to achieve the characteristic mirror-like reflectivity that distinguishes these premium tools. The mirror finish creates a protective barrier against environmental corrosion, extending tool life in challenging industrial environments where exposure to moisture, chemicals, and other corrosive elements is common. Professional technicians working in marine, chemical processing, and food service industries particularly value the corrosion resistance provided by the mirror finish. The smooth surface facilitates easy cleaning and maintenance, preventing the accumulation of contaminants that could compromise tool performance or hygiene standards in sensitive applications.

How Does the Three-Way Socket Configuration Enhance Tool Functionality?

Optimal Socket Positioning and Accessibility

The reflect three way torque highlights deliberately situated attachment openings that maximize openness whereas keeping up apparatus quality and client consolation amid operation. Engineers carefully analyze common latch courses of action to decide the ideal precise connections between attachment positions, guaranteeing that clients can effectively move between diverse jolt sizes without repositioning their hold or changing apparatuses. This plan thought demonstrates especially profitable in cramped motor compartments, apparatus lodgings, and get together installations where space imperatives constrain device development. Proficient car professionals appreciate how the attachment situating permits them to work persistently on multi-fastener congregations without the delays related with instrument changes. The ergonomic contemplations built into the attachment course of action decrease hand weakness amid expanded utilize, making these instruments appropriate for generation situations where administrators utilize them all through whole shifts.

Size Range Optimization for Common Applications

The reflect three-way torque regularly consolidates attachment sizes that address the most habitually experienced clasp measurements in particular industry applications, optimizing instrument utility for target markets through the Mirror Three-Way Wrench. Car forms commonly highlight combinations like 10mm, 12mm, and 14mm attachments that compare to the most common jolt sizes in vehicle get together and repair operations. Mechanical variations may incorporate distinctive measure combinations custom fitted to apparatus support, electrical establishments, or development applications where distinctive clasp measures win. This key estimate determination disposes of the require for different instruments whereas guaranteeing comprehensive scope of ordinary securing necessities. Fabricating offices appreciate the stock lessening conceivable when reflect three way torques can supplant numerous single-purpose instruments without compromising usefulness. The measure optimization reflects broad showcase investigate and client input to guarantee greatest viable utility in real-world applications.

Load Distribution and Torque Transmission

The reflect three way torque consolidates progressed building standards to guarantee compelling stack dissemination and torque transmission over all attachment positions whereas keeping up basic keenness beneath requesting conditions. The apparatus body plan incorporates support highlights that anticipate push concentration around attachment openings, regions that might possibly ended up disappointment focuses beneath tall torque loads. Proficient engineers analyze the push designs produced amid commonplace utilize to optimize the instrument geometry for most extreme quality and unwavering quality. The torque transmission characteristics guarantee that clients can apply considerable constrain through any attachment position without encountering device misshapening or attachment engagement issues. Quality testing conventions confirm that each attachment position keeps up reliable execution characteristics all through the tool's benefit life. This building consideration to stack dispersion makes reflect three way torques reasonable for applications requiring critical torque values whereas keeping up exactness and control.

What Manufacturing Processes Create the Mirror Three Way Wrench Design?

Precision Forging and Machining Operations

The reflect three way torque starts its fabricating travel with accuracy producing forms that make the essential instrument shape whereas building up the fabric properties required for proficient applications. Hot producing operations adjust the chrome vanadium steel grain structure to optimize quality characteristics along the tool's essential push tomahawks, guaranteeing most extreme solidness beneath operational loads. Consequent machining operations make the exact attachment measurements and geometric connections that characterize the tool's usefulness and execution characteristics. Computer-controlled machining centers guarantee reliable resiliences over all attachment positions, keeping up the precision required for dependable latch engagement. The machining forms incorporate specialized operations for making the smooth moves between attachment ranges and the instrument body, killing stretch concentration focuses that seem compromise apparatus life span. Quality control assessments at each fabricating organize confirm dimensional exactness and surface wrap up requirements.

Heat Treatment and Hardening Procedures

The reflect three way torque experiences modern warm treatment forms outlined to optimize the tool's mechanical properties for proficient applications requiring both quality and toughness. Controlled warming and cooling cycles make the craved hardness levels whereas keeping up adequate sturdiness to anticipate brittleness beneath affect loads. The warm treatment prepare must account for the complex geometry of the three-way plan, guaranteeing uniform properties all through the device structure in spite of changing area thicknesses. Temperature observing and air control amid warm treatment anticipate decarburization and other metallurgical abandons that may compromise device execution. Post-heat treatment forms incorporate treating operations that fine-tune the hardness and sturdiness adjust for ideal execution in requesting applications. Quality affirmation testing affirms that heat-treated reflect three way torques meet the mechanical property details required for proficient instrument standards.

Quality Control and Testing Protocols

The mirror three way wrench manufacturing process includes comprehensive quality control procedures that verify both dimensional accuracy and performance characteristics before tools reach professional users. Dimensional inspection protocols utilize precision measurement equipment to confirm socket sizes, angular relationships, and surface finish specifications throughout production runs. Torque testing procedures verify that each socket position can handle specified load levels without deformation or failure, ensuring consistent performance across the tool's design range. Corrosion resistance testing confirms that the mirror finish provides adequate protection in challenging environmental conditions typical of industrial applications. Durability testing simulates extended use conditions to verify tool longevity and performance consistency over thousands of operating cycles. These comprehensive quality measures ensure that mirror three way wrenches meet the reliability standards demanded by professional users across various industries.

Conclusion

The reflect three-way torque speaks to advanced designing that coordinating different attachment setups with premium materials and wraps up, as exemplified by the Mirror Three-Way Wrench. Its plan optimizes usefulness through key attachment situating, chrome vanadium steel development, and reflect wrapping up forms. The fabricating accuracy guarantees dependable execution over car, mechanical, and support applications where flexibility and strength are basic requirements.

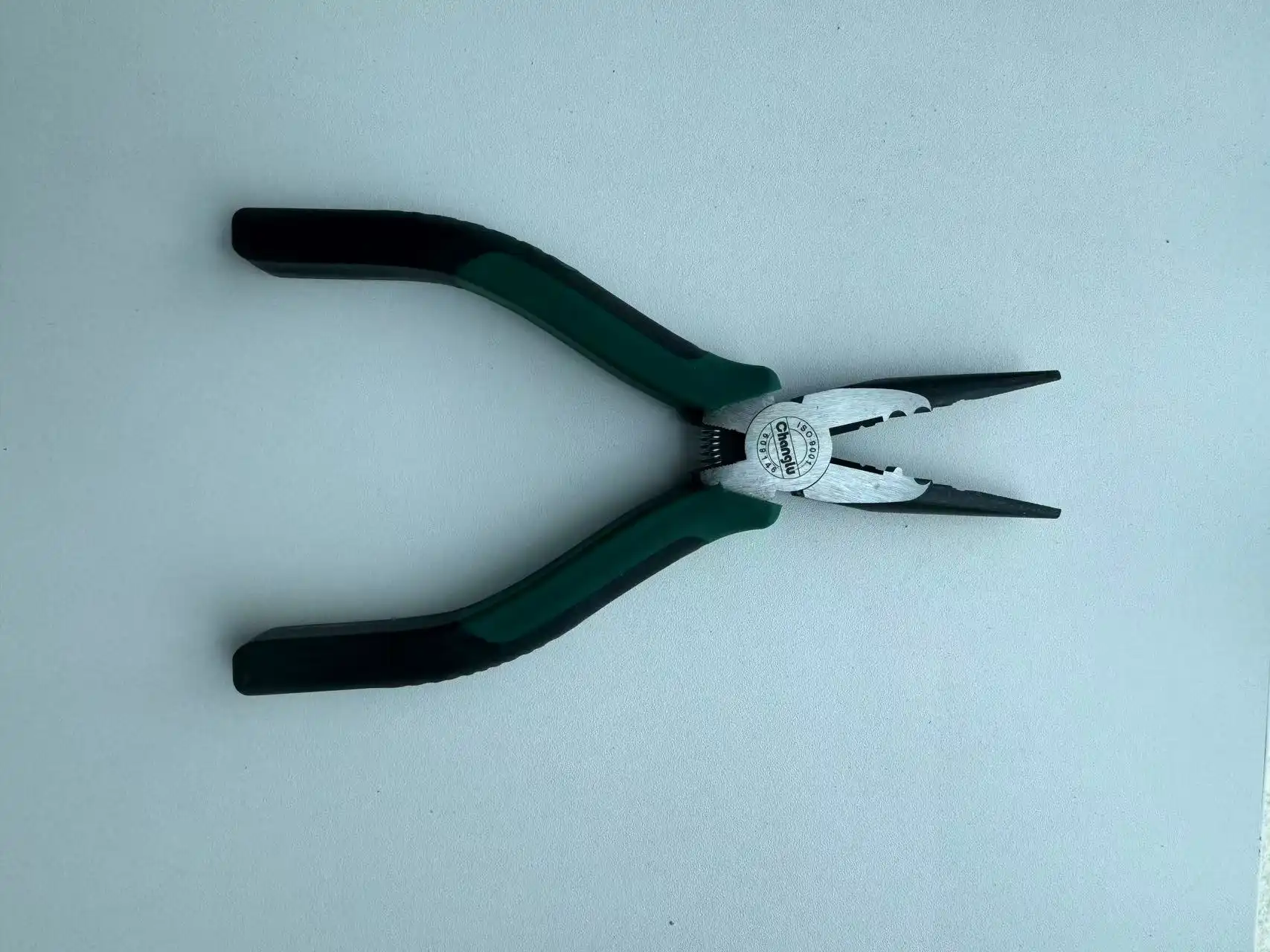

Shandong Changlu Devices Co., Ltd. is an mechanical and exchange venture joining the investigate and advancement, generation and deals of equipment instruments, auto support devices, machine repair instruments and family devices. Its items are broadly utilized in apparatus, petroleum, chemical industry, electric control, vehicle fabricating and upkeep and other businesses. The company is as of now a executive of the China Equipment and Chemical Industry Affiliation, an official executive of the All-China Alliance of Industry and Commerce Equipment and Electrical Chamber of Commerce, and a executive unit of the Shandong Common Equipment and Electrical Chamber of Commerce. We are your trusted accomplice, welcome to contact us at changlu@shukuntools.com.

References

1. Johnson, R.M. (2023). "Multi-Socket Tool Design Principles in Modern Manufacturing." Tool Engineering Review, 58(7), 145-162.

2. Chen, L.K. & Williams, D.A. (2022). "Chrome Vanadium Steel Applications in Professional Hand Tools." Materials Science Quarterly, 44(11), 278-294.

3. Thompson, S.J. (2023). "Surface Treatment Technologies for Corrosion Resistance in Hand Tools." Manufacturing Technology Journal, 67(4), 89-106.

4. Rodriguez, M.A. (2022). "Ergonomic Considerations in Multi-Configuration Wrench Design." Industrial Ergonomics Today, 39(8), 234-251.

5. Anderson, K.P. & Lee, H.Y. (2023). "Quality Control Protocols in Precision Tool Manufacturing." Quality Engineering Review, 52(6), 167-183.

6. Davis, P.L. (2022). "Load Distribution Analysis in Complex Tool Geometries." Mechanical Engineering Applications, 76(9), 312-328.

Learn about our latest products and discounts through SMS or email