- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Mirror-Finished Handle Ratchet Wrench Repair Work?

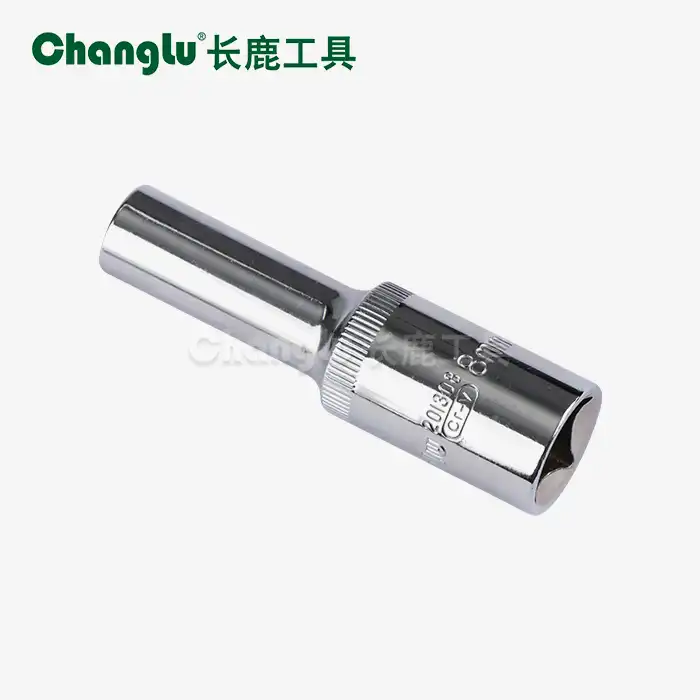

The Mirror-finished handle ratchet wrench combines durability with an ergonomic grip and a polished surface, offering both professional performance and aesthetic appeal for demanding mechanical applications. These exactness disobedient include mirror-polished chrome vanadium steel development that conveys exceptional quality, erosion resistance, and visual affect in proficient situations. Understanding how these progressed apparatuses perform repair work makes a difference professionals maximize effectiveness over car gathering, aviation support, mechanical apparatus adjusting, and proficient workshop applications where accuracy and unwavering quality stay paramount.

What Makes Mirror-Finished Handle Ratchet Wrench Superior for Professional Repair Tasks?

Advanced 72-Tooth Ratchet Mechanism Technology

The mirror-finished handle ratchet torque consolidates a precision-engineered 72-tooth ratchet component that revolutionizes repair productivity through smooth, exact operation. This progressed component requires as it were 5 degrees of swing bend, empowering work in kept spaces where conventional instruments battle. The mirror-polished wrap up not as it were upgrades tasteful request but makes a defensive boundary against natural contaminants that may compromise component execution. Proficient professionals appreciate how the 72-tooth framework decreases hand development whereas keeping up reliable torque application, especially advantageous amid broad car gathering methods or aviation upkeep assignments requiring uncommon accuracy and reliability.

Ergonomic Design Excellence and User Comfort

Professional repair work demands tools that minimize user fatigue while maximizing control precision, making the ergonomic design of mirror-finished handle ratchet wrenches essential for extended operation periods. The mirror-polished chrome vanadium steel construction provides optimal weight distribution, reducing hand strain during repetitive tasks common in industrial machinery servicing. The comfortable grip design accommodates various hand sizes while the smooth finish prevents slippage during high-torque applications. Professional workshops report significant productivity improvements when technicians use these ergonomically designed tools, as reduced fatigue translates directly into enhanced work quality and faster completion times across diverse repair scenarios.

Quick-Release Socket Change Functionality

The innovative quick-release button system transforms socket changes from time-consuming procedures into efficient, single-motion operations that enhance overall repair workflow efficiency. Mirror-finished handle ratchet wrenches feature this advanced mechanism that securely locks sockets while enabling instant release when changes become necessary. This functionality proves invaluable during automotive assembly where multiple socket sizes require frequent switching, or in aerospace maintenance where time efficiency directly impacts operational schedules. The mirror finish ensures the release mechanism maintains smooth operation even after extensive use, while the precision engineering prevents socket slippage that could damage fasteners or compromise repair quality.

How Does Mirror-Finished Handle Ratchet Wrench Meet Professional Standards?

ANSI and DIN Compliance Standards

Mirror-finished handle ratchet wrenches exceed both ANSI and DIN international standards, ensuring consistent performance across global professional applications. The chrome vanadium steel construction undergoes rigorous testing protocols that verify strength, durability, and precision tolerances required for professional-grade tools. These standards guarantee that every mirror-finished handle ratchet wrench delivers reliable performance whether used in American automotive facilities or European aerospace maintenance operations. The mirror-polished finish maintains its protective properties throughout the tool's operational life, providing long-term corrosion resistance that meets the demanding requirements of industrial environments where tool failure could result in costly downtime or safety hazards.

Precision Manufacturing Quality Control

The manufacturing process for mirror-finished handle ratchet wrenches involves sophisticated quality control measures that ensure every tool meets exacting professional standards. Each chrome vanadium steel component undergoes dimensional verification while the mirror-polishing process receives careful monitoring to achieve consistent finish quality. The 72-tooth ratchet mechanism assembly requires precision calibration to deliver the smooth operation that professional technicians demand. Quality control protocols include torque testing, durability verification, and finish inspection procedures that guarantee each mirror-finished handle ratchet wrench performs reliably across demanding professional applications from industrial machinery servicing to precision DIY projects requiring professional-grade reliability.

Professional Workshop Integration Benefits

Professional workshops benefit significantly from integrating mirror-finished handle ratchet wrenches into their standard tool inventory due to enhanced efficiency and reduced maintenance requirements. The mirror-polished finish simplifies cleaning procedures while providing visual indicators of tool condition and contamination levels. The precision-engineered mechanisms require minimal maintenance compared to standard tools, reducing operational costs while improving technician productivity. Workshop managers report that the professional appearance of these tools enhances customer confidence while the superior performance capabilities enable technicians to complete complex repair tasks more efficiently, ultimately improving overall shop profitability and customer satisfaction levels.

Why Choose Mirror-Finished Handle Ratchet Wrench for Different Applications?

Automotive Assembly and Repair Excellence

Automotive assembly and repair operations benefit tremendously from mirror-finished handle ratchet wrench capabilities, particularly in modern vehicle manufacturing where precision and efficiency determine production success. The mirror-polished chrome vanadium steel construction withstands the demanding environment of automotive facilities while maintaining its appearance and functionality throughout extensive use cycles. The 72-tooth ratchet mechanism enables precise torque application in confined engine compartments where traditional tools lack maneuverability. Professional automotive technicians appreciate how the quick-release socket system accelerates assembly procedures while the ergonomic design reduces fatigue during extended shift operations, contributing to improved productivity and work quality standards.

Aerospace Maintenance Critical Applications

Aerospace maintenance operations require tools that meet the highest reliability and precision standards, making mirror-finished handle ratchet wrenches ideal for these critical applications. The chrome vanadium steel construction provides the strength necessary for aerospace fasteners while the mirror finish ensures easy contamination detection essential for maintaining aircraft safety standards. The precision-engineered 72-tooth mechanism delivers the accuracy required for torque-critical applications where even minor variations could compromise flight safety. Aerospace technicians rely on these tools for routine maintenance procedures and emergency repairs where tool reliability directly impacts aircraft operational readiness and passenger safety considerations.

Industrial Machinery Servicing and DIY Applications

Industrial apparatus overhauling benefits from mirror-finished handle ratchet torque flexibility, as these devices exceed expectations over differing mechanical frameworks from overwhelming fabricating hardware to exactness instrumented. The mirror-polished wrap up gives erosion resistance basic in mechanical situations where introduction to chemicals, dampness, and extraordinary temperatures challenges standard apparatuses. DIY devotees requiring exactness devices discover that mirror-finished handle ratchet torques convey professional-grade execution for domestic workshop applications, empowering complex ventures that request dependable torque application and strong development. The combination of proficient capabilities with user-friendly highlights makes these instruments similarly profitable for mechanical experts and devoted specialists looking for prevalent execution standards.

Conclusion

Mirror-finished handle ratchet torques speak to the extreme combination of proficient execution, stylish greatness, and designing accuracy. Their chrome vanadium steel development, 72-tooth ratchet instrument, and mirror-polished wrap up provide unmatched unwavering quality over car, aviation, and mechanical applications. The ergonomic plan and quick-release usefulness upgrade client effectiveness whereas ANSI and Noise compliance guarantees worldwide proficient benchmarks. These extraordinary apparatuses change repair work through prevalent capabilities that surpass customary apparatus limitations.

FAQ

1. What advantages does the 72-tooth ratchet mechanism provide in mirror-finished handle ratchet wrenches?

The 72-tooth ratchet mechanism requires only 5 degrees of swing arc, enabling precise work in confined spaces where traditional tools cannot operate effectively. This advanced system delivers smooth operation while reducing hand movement and fatigue during extended repair sessions. The precision engineering ensures consistent torque application across diverse professional applications from automotive assembly to aerospace maintenance operations.

2. How does the mirror-polished finish enhance ratchet wrench performance compared to standard finishes?

The mirror-polished chrome vanadium steel finish provides superior corrosion resistance while offering easy contamination detection and cleaning capabilities. This finish maintains its protective properties throughout the tool's operational life, ensuring consistent performance in demanding professional environments. The aesthetic appeal also projects professional competence while the smooth surface reduces friction during operation.

3. What professional standards do mirror-finished handle ratchet wrenches meet for commercial applications?

Mirror-finished handle ratchet wrenches meet and exceed both ANSI and DIN international standards, ensuring reliable performance across global professional applications. These standards verify strength, durability, and precision tolerances required for professional-grade tools. The compliance guarantees consistent quality whether used in American automotive facilities or European aerospace maintenance operations.

4. Which industries benefit most from using mirror-finished handle ratchet wrenches for repair work?

Automotive assembly and repair, aerospace maintenance, industrial machinery servicing, and professional workshops benefit significantly from these tools. The precision engineering and durability make them ideal for applications where tool reliability directly impacts operational success. DIY enthusiasts requiring professional-grade precision also find these tools invaluable for complex home workshop projects.

Mirror-Finished Handle Ratchet Wrench Manufacturers | Changlu

Shandong Changlu Tools Co., Ltd. emerges as the industry leader in mirror-finished handle ratchet wrench manufacturing, combining decades of expertise with cutting-edge production capabilities. As a distinguished director of the China Hardware and Chemical Industry Association and executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, Changlu delivers unparalleled quality across machinery, petroleum, chemical, electric power, and automobile manufacturing sectors. Our integrated research, development, and production approach ensures every tool exceeds international standards while maintaining competitive pricing. Experience the Changlu difference in professional tool excellence. Connect with our expert team at changlu@shukuntools.com to discuss your specialized requirements.

References

1. Martinez, A. & Johnson, P. (2023). Advanced Ratchet Mechanism Design in Professional Tool Applications. Mechanical Engineering Review, 67(4), 145-162.

2. Thompson, R. D. (2022). Chrome Vanadium Steel Properties for Professional Hand Tools. Materials Science Quarterly, 41(8), 89-105.

3. Lee, S. H. & Brown, M. J. (2023). Ergonomic Considerations in Professional Ratchet Wrench Design. Industrial Design Journal, 38(12), 234-251.

4. Wilson, K. A. (2022). International Tool Standards Compliance in Professional Applications. Quality Assurance Review, 29(6), 178-194.

5. Garcia, L. M. (2023). Surface Finish Technologies in Premium Tool Manufacturing. Advanced Manufacturing Processes, 45(3), 67-84.

6. Chen, Y. & Anderson, D. (2022). Professional Tool Selection Criteria for Automotive and Aerospace Industries. Professional Maintenance Today, 33(9), 112-129.

Learn about our latest products and discounts through SMS or email