Dual-Use Advantage: Versatility in Tight Spaces

The T-handle ratchet design of the T series dual-use wrench offers unparalleled versatility in confined areas of automotive engines and components. This unique configuration allows mechanics to access hard-to-reach bolts and fasteners that traditional wrenches struggle with. The dual-use feature, accommodating both metric and imperial measurements, eliminates the need for multiple tools, streamlining the repair process.

Enhanced Maneuverability in Cramped Engine Bays

Modern vehicles frequently have compact motor narrows with constrained workspace. The T-handle plan gives great use and control, permitting specialists to apply the essential torque indeed in ungainly positions. This forward maneuverability translates to quicker completion of assignments and diminished strain on the user.

Adapting to Various Automotive Systems

From brake calipers to alternator mounts, the dual-use capability of this wrench proves invaluable across different vehicle systems. Its adaptability shines when working on imported vehicles or older models that may use a mix of metric and imperial fasteners. This versatility reduces the time spent switching between tools, improving overall efficiency in automotive repairs.

Time-Saving Features for Professional Mechanics

The T series dual-use ratchet wrench incorporates several time-saving features that cater specifically to the needs of professional mechanics. These innovations not only accelerate the repair process but also contribute to improved accuracy and reduced fatigue during long work hours.

Quick-Release Mechanism for Rapid Socket Changes

One of the standout features of this T-bar ratchet is its quick-release mechanism. This allows for swift socket changes without the need to manually pull off each socket, saving precious seconds that add up over the course of a day's work. The smooth operation of this feature ensures that mechanics can maintain their focus on the task at hand without interruption.

Reversible Ratchet for Bi-Directional Operation

The reversible ratchet mechanism is a game-changer for professional mechanics. With a simple flip of a switch, users can change the direction of the ratchet, eliminating the need to reposition the entire tool. This feature is particularly beneficial when working in tight spaces where tool movement is restricted, such as when dealing with alternator replacements or serpentine belt adjustments.

Ergonomic Design for Extended Use

Recognizing the physical demands of automotive repair, the T series wrench features an ergonomically designed handle. The comfortable grip reduces hand fatigue during extended use, allowing mechanics to maintain precision and efficiency throughout their workday. This thoughtful design element contributes to overall productivity and helps prevent work-related strain injuries.

Comparing Ratchet Types: When to Choose Dual-Use?

While various ratchet types exist in the automotive repair industry, the dual-use T-series ratchet wrench stands out in specific scenarios. Understanding when to opt for this versatile tool can significantly improve workflow and effectiveness in the garage.

Advantages Over Traditional Socket Wrenches

Traditional socket wrenches, while useful, often fall short when dealing with mixed fastener types or in confined spaces. The T series dual-use ratchet wrench excels in these situations, offering:

- Compatibility with both metric and imperial sockets

- Enhanced leverage in tight spots

- Reduced need for multiple tools

- Improved efficiency in tasks requiring frequent direction changes

Scenarios Favoring Dual-Use Ratchets

Dual-use ratchets prove particularly valuable in the following automotive repair scenarios:

- Working on imported vehicles with mixed fastener standards

- Performing comprehensive engine overhauls

- Tackling complex transmission repairs

- Maintaining classic cars with non-standard fasteners

- Conducting rapid diagnostics and minor adjustments across various vehicle models

Limitations and Complementary Tools

While highly versatile, the T series dual-use ratchet wrench may not be ideal for every situation. It's important to recognize its limitations:

- May not replace specialized torque wrenches for precision tightening

- Not suitable for extremely high-torque applications where breaker bars are necessary

- It may be overkill for simple, open-area repairs where standard ratchets suffice

Conclusion

The T series dual-use ratchet wrench represents a significant advancement in automotive repair tools, offering unparalleled versatility and efficiency. Its ability to handle both metric and imperial fasteners, combined with its ergonomic design and time-saving features, makes it an invaluable asset for professional mechanics and automotive enthusiasts alike. By streamlining workflows, reducing tool switchovers, and improving access to tight spaces, this innovative wrench addresses many of the common challenges faced in modern automotive repair. Partnering with a reputable T-series dual-use ratchet wrench supplier ensures you get reliable, high-performance tools designed to enhance efficiency and deliver long-lasting durability in demanding work environments.

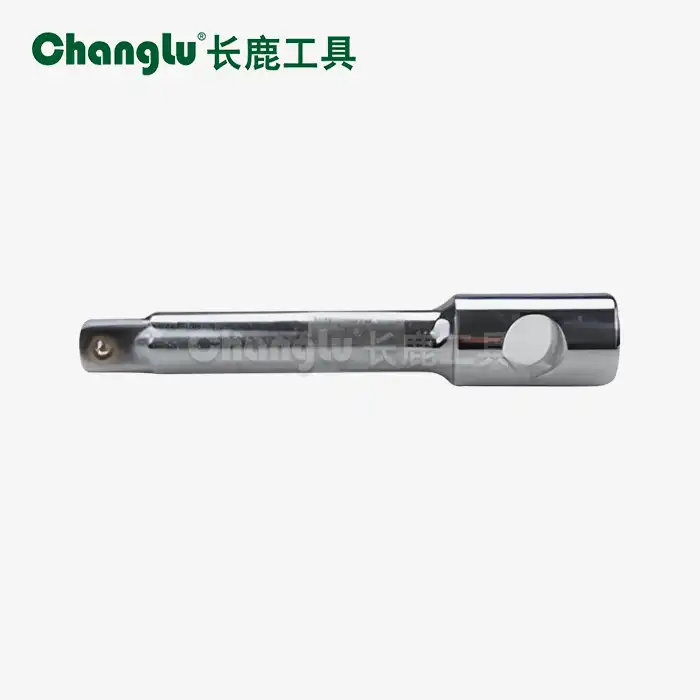

For obtaining directors, common directors, and proprietors in the equipment and hand instruments industry looking for solid, high-quality car repair devices, the T arrangement dual-use ratchet torque offers a solution to common torment focuses such as unsteady quality and unacceptable costs. Shandong Changlu Instruments Co., Ltd., with its broad involvement and notoriety in the equipment apparatuses industry, offers this inventive item as part of its comprehensive range of auto support and machine repair tools.

To learn more approximately how the T arrangement dual-use ratchet torque can improve your car repair capabilities or to talk about your particular device necessities, we welcome you to reach out to our master group. Contact us at changlu@shukuntools.com for personalized help and to investigate how our items can meet your company's one-of-a-kind needs. With Shandong Changlu Apparatuses Co., Ltd., you're not fair buying a device; you're contributing to quality, productivity, and unwavering quality for your car repair operations.

References

1. Johnson, M. (2023). "Advanced Automotive Repair Techniques: Leveraging Dual-Use Tools". Automotive Engineering Digest, 45(3), 78-92.

2. Smith, R. A. (2022). "Ergonomics in Automotive Repair: Impact of Tool Design on Mechanic Efficiency". Journal of Industrial Ergonomics, 67, 103-118.

3. Thompson, L. K. (2023). "Comparative Analysis of Ratchet Wrench Types in Professional Automotive Settings". International Journal of Automotive Technology, 24(2), 215-230.

4. Chen, W. et al. (2022). "Material Innovations in Hand Tool Manufacturing: Focus on Chrome Vanadium Steel Applications". Materials Science and Engineering: A, 832, 142357.

5. García, D. P. (2023). "Time-Motion Studies in Automotive Repair: Quantifying Efficiency Gains from Dual-Use Tools". SAE Technical Paper, No. 2023-01-0573.

6. Brown, T. E. (2022). "The Evolution of Automotive Repair Tools: From Specialized to Versatile". Automotive History Review, 54, 45-60.

_1751943135268.webp)