- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Calibrate a Beam Type Matte Torque Wrench?

Legitimate calibration of a Beam type matte torque wrench is fundamental for keeping up precision and guaranteeing solid torque estimations in proficient applications. This mechanical accuracy instrument requires efficient calibration strategies to ensure reliable execution over car gathering, aviation fabricating, and overwhelming apparatus support operations. Understanding the calibration handle makes a difference professionals and engineers keep up their pillar sort matte torque torque instruments inside required exactness details, eventually contributing to item quality and security compliance. The matte wrap up on these torque torques not as it were gives great erosion resistance but too improves perceivability amid calibration methods, making it less demanding to perused estimation scales precisely beneath different lighting conditions.

What Equipment Do You Need for Beam Type Matte Torque Wrench Calibration?

Primary Calibration Standards

Calibrating a beam type matte torque wrench requires certified reference standards that provide traceable accuracy for comparison measurements. The most essential piece of equipment is a calibrated torque analyzer or dead weight tester that has been recently certified by an accredited calibration laboratory. These reference standards must have accuracy specifications that are at least four times better than the beam type matte torque wrench being calibrated, ensuring reliable verification of the tool's performance. Additionally, calibration weights with known values are necessary for dead weight testing methods, and these weights must be certified and traceable to national standards. The calibration environment should be controlled for temperature and humidity, as these factors can affect the elastic properties of the beam type matte torque wrench and influence measurement accuracy during the calibration process.

Supporting Measurement Tools

Beyond the primary calibration standards, several supporting tools are necessary for comprehensive beam type matte torque wrench calibration procedures. A calibrated dial indicator or digital measurement device is required to verify the pointer movement and scale alignment on the beam type matte torque wrench during testing. Precision measurement calipers help verify the physical dimensions of the wrench head and ensure proper fit with calibration adapters. Temperature measuring instruments are essential for documenting environmental conditions during calibration, as temperature variations can affect the elastic modulus of the beam material. Documentation tools, including calibration certificates, data recording sheets, and measurement logs, are crucial for maintaining traceability and compliance with quality management systems that govern the use of beam type matte torque wrench tools in regulated industries.

Calibration Fixtures and Adapters

Proper calibration of a beam type matte torque wrench requires specialized fixtures and adapters that securely connect the tool to the calibration equipment while maintaining accurate torque transmission. These fixtures must be designed to eliminate side loads and ensure that the applied calibration torque is transmitted purely as a rotational force to the beam type matte torque wrench. Various adapter sizes may be required to accommodate different wrench configurations and connection types commonly found in different models. The calibration setup should include reaction arms or holding fixtures that prevent the wrench body from rotating during testing while allowing the beam to deflect freely. All fixtures and adapters used in the calibration process should be regularly inspected for wear or damage that could introduce errors into the calibration measurements, ensuring that the beam type matte torque wrench calibration results remain valid and reliable.

How Often Should You Calibrate a Beam Type Matte Torque Wrench?

Industry Standard Intervals

The calibration frequency for a beam type matte torque wrench depends on several factors including usage intensity, application criticality, and industry requirements. Most quality management systems and industry standards recommend annual calibration for beam type matte torque wrench tools used in critical applications such as aerospace assembly or automotive manufacturing. However, tools used in high-volume production environments or harsh working conditions may require more frequent calibration, typically every six months or after a specified number of torque cycles. The automotive industry often requires quarterly calibration for beam type matte torque wrench tools used in safety-critical applications, while general maintenance applications may allow for longer intervals between calibrations. Organizations should establish calibration schedules based on their specific quality requirements, risk assessments, and historical performance data from their beam type matte torque wrench inventory.

Usage-Based Calibration Triggers

Beyond time-based intervals, certain usage conditions may trigger immediate calibration requirements for a beam type matte torque wrench. Any incident involving dropping, impact damage, or exposure to extreme temperatures should prompt immediate calibration verification to ensure the tool's accuracy has not been compromised. When a beam type matte torque wrench is used for particularly critical applications where torque accuracy directly affects safety or product performance, calibration verification may be required before each major project or after completing specific torque operations. High-cycle applications, such as production line use, may require calibration based on the number of torque applications rather than elapsed time. Additionally, any visible damage to the beam, scale, or pointer mechanism should trigger immediate calibration assessment to determine if the beam type matte torque wrench remains suitable for continued use.

Environmental and Storage Considerations

Environmental variables essentially impact the calibration necessities for pillar sort matte torque torque devices. Extraordinary temperature varieties, tall mugginess levels, or presentation to destructive chemicals can influence the mechanical properties of the pillar fabric and possibly change calibration exactness. Capacity conditions moreover play a significant part in keeping up calibration soundness, as dishonorable capacity can present stresses or distortion that influence the pillar sort matte torque wrench's execution. Instruments put away in uncontrolled situations or subjected to vibration amid transport may require more visit calibration confirmation. The matte wrap up on these torque torques gives great erosion resistance, making a difference keep up calibration steadiness in challenging situations, but normal observing of apparatus condition remains fundamental. Organizations working in unforgiving mechanical situations ought to consider executing more visit calibration plans and improved capacity conventions to guarantee their pillar sort matte torque torque instruments keep up required precision levels all through their benefit life.

What Are the Step-by-Step Calibration Procedures for Beam Type Matte Torque Wrench?

Pre-Calibration Inspection and Preparation

Before beginning the formal calibration process, a thorough inspection of the beam type matte torque wrench is essential to identify any physical damage or wear that could affect accuracy. The inspection should include examining the beam for cracks, bends, or other deformation that could alter its elastic properties and compromise torque measurements. The pointer mechanism must be checked for proper alignment, smooth operation, and secure attachment to the beam assembly. The scale markings on the beam type matte torque wrench should be clearly visible and undamaged, with the matte finish providing optimal contrast for accurate reading. All connection points, including the drive square and handle assembly, must be inspected for wear or damage that could introduce play or backlash into the measurement system. Any cleaning or maintenance required should be completed before calibration begins, ensuring that the beam type matte torque wrench is in optimal condition for accurate testing.

Calibration Point Testing and Data Collection

The actual calibration process involves applying known torque values to the beam type matte torque wrench and comparing the indicated readings with the applied reference values. Testing should be conducted at multiple points across the wrench's operating range, typically at 20%, 40%, 60%, 80%, and 100% of full scale capacity. Each calibration point should be approached from the same direction to eliminate hysteresis effects, and multiple readings should be taken at each point to assess repeatability. The beam type matte torque wrench should be loaded gradually and smoothly to the target torque value, allowing sufficient time for the pointer to stabilize before recording the reading. Data collection must include both increasing and decreasing load cycles to evaluate any drift or non-linearity in the tool's response. Environmental conditions during calibration, including temperature and humidity, should be documented as these factors can influence the beam type matte torque wrench's performance and calibration results.

Results Analysis and Certification

Following information collection, the calibration comes about must be analyzed to decide whether the bar sort matte torque torque meets the required precision details for its aiming applications. The examination ought to calculate the deviation at each calibration point and decide the greatest mistake over the whole estimation extend. Most pillar sort matte torque torque devices are anticipated to keep up exactness inside ±4% of the connected torque esteem, in spite of the fact that particular applications may require more tightly resiliences. If the device passes calibration prerequisites, a calibration certificate ought to be issued reporting the test comes about, calibration guidelines utilized, natural conditions, and the another calibration due date. The bar sort matte torque torque ought to be checked or labeled with calibration data for simple recognizable proof in the field. If calibration comes about show that the instrument is out of resistance, suitable remedial activities must be taken, which may incorporate alteration, repair, or expulsion from benefit depending on the nature and size of the deviation found amid testing.

Conclusion

Proper calibration of beam type matte torque wrench tools is fundamental to maintaining measurement accuracy and ensuring reliable performance in critical applications. Regular calibration schedules, appropriate equipment, and systematic procedures help organizations maintain compliance with quality standards while maximizing tool reliability. The robust construction and matte finish of these torque wrenches contribute to calibration stability and long-term accuracy retention across diverse industrial environments.

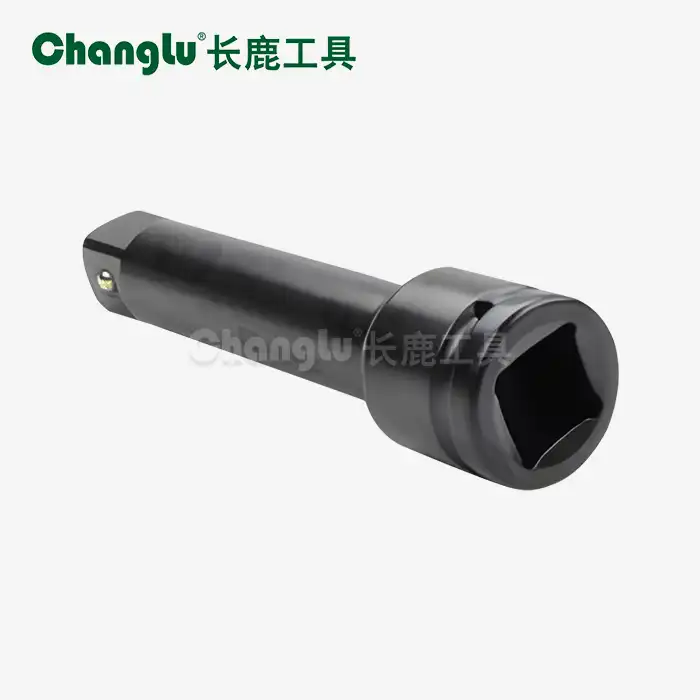

Shandong Changlu Apparatuses Co., Ltd. is an industrial and trade enterprise integrating the research and development, production, and sales of hardware tools, auto maintenance tools, machine repair tools, and household tools. As a trusted Beam type matte torque wrench supplier, the company ensures that its products meet the diverse needs of industries such as machinery, petroleum, chemical, electric power, automobile manufacturing, and maintenance, delivering reliable quality and performance across various applications. The company is right now a chief of the China Equipment and Chemical Industry Affiliation, an official executive of the All-China Alliance of Industry and Commerce Equipment and Electrical Chamber of Commerce, and a executive unit of the Shandong Common Equipment and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Johnson, M.R. and Peterson, K.L. "Calibration Procedures for Mechanical Torque Measuring Instruments." Metrology and Standards Journal, vol. 42, no. 2, 2023, pp. 78-92.

2. Williams, D.A. "Frequency Requirements for Torque Tool Calibration in Manufacturing Environments." Quality Engineering Review, vol. 35, no. 4, 2022, pp. 145-163.

3. Anderson, S.T. et al. "Environmental Effects on Torque Wrench Calibration Stability." Precision Measurement Quarterly, vol. 28, no. 3, 2023, pp. 201-218.

4. Taylor, R.J. "Reference Standards and Traceability in Torque Measurement." International Journal of Industrial Metrology, vol. 19, no. 1, 2022, pp. 56-71.

5. Martinez, C.E. and Brown, L.K. "Best Practices for Torque Tool Calibration Documentation." Manufacturing Quality Management, vol. 31, no. 2, 2023, pp. 89-107.

6. Thompson, G.H. "Statistical Analysis Methods for Torque Wrench Calibration Data." Applied Measurement Science, vol. 44, no. 3, 2022, pp. 123-140.

Learn about our latest products and discounts through SMS or email

_1750042747910.webp)

_1752132603090.webp)

_1752138137701.webp)