Understanding the Importance of Torque Wrenches in Automotive Repairs

Torque wrenches are very important for car repairs since they make sure that nuts and screws are tightened to the right level. This level of accuracy is very important for a number of reasons:

Safety and Dependability

Fasteners that are properly torqued keep parts from falling loose while they are in use, which could cause major problems. For example, if the wheel lug nuts aren't tightened to the right torque specification, the wheel could come off while you're driving. This is a dangerous circumstance that shows how important it is to use a calibrated torque wrench.

Keeping Things Safe

If you tighten something too much, it can break or strip threads, which can harm parts. If you don't tighten things enough, they may come loose over time. With a lightweight torque wrench, you can apply the right amount of force without damaging the pieces of your car.

Keeping the Warranty

Many car companies list the torque requirements for different parts. Using a torque wrench makes sure that repairs are done to factory standards, which is often needed to keep the warranty in effect.

Repairs that are always the same

Torque wrenches make sure that repairs are done the same way every time and by various mechanics. In professional settings where more than one expert may operate on the same car, this uniformity is quite crucial.

It's easy to see why it's important to choose the best adjustable aluminum torque wrench and keep it properly calibrated for any major car work and beyond.

Key Features to Consider When Selecting an Adjustable Aluminum Torque Wrench

There are a few important things to think about when buying an adjustable aluminum torque wrench to make sure you purchase a tool that will work for you and last for a long time:

Correctness and exactness

Find wrenches that have good accuracy ratings. Most automotive applications work best with a tolerance of ±4% or better. Some high-end models have even tighter tolerances, which might be helpful for certain tasks.

Torque Range

Think about how much torque you'll need for the kinds of projects you usually do. For car work, you usually need a range of 20 to 200 Nm, but this can change depending on what you're doing. Make sure the wrench you purchase covers the range you need.

Readability of the Scale

It should be easy to read and understand the torque scale. Some devices have dual-range scales (such Nm and ft-lbs) to make things easier. Digital displays can be more accurate and easier to use.

Quality of the Build and Materials

Aluminum is a great choice because it is both strong and light. Find wrenches with high-quality finishes that won't rust or wear down. The ratchet mechanism should work smoothly and accurately.

Comfort and ergonomics

Think on how the wrench's handle looks and how well it balances. A comfortable grip is important for precise control and less tiredness when using it for a long time.

Features for Calibration

Some wrenches have built-in calibration indications or calibration locations that are easy to get to. These characteristics can make it easier to keep things correct over time.

More Features

Look for essential extras like storage cases, different disk sizes that you can switch out, or built-in conversion tables. These can make your torque wrench more useful and easier to use.

You may choose an adjustable aluminum torque wrench that will last you for years by carefully thinking about these qualities. Keep in mind that buying a good tool up front will save you time, irritation, and blunders that could cost you a lot of money later on.

Proper Calibration Techniques for Adjustable Aluminum Torque Wrenches

To make sure that your adjustable aluminum torque wrench works reliably while you fix cars, you need to keep it calibrated correctly. Here's a step-by-step guide on how to properly calibrate your torque wrench:

Understanding how often to calibrate

To keep accuracy, you need to calibrate regularly. In general:

- Before using a new torque wrench for the first time, set it up correctly.

- You should recalibrate it after 5,000 uses or 12 months, whichever comes first.

- If the wrench is dropped or hit too hard, calibrate it right away.

Ways to calibrate

There are two main ways to calibrate torque wrenches:

- Services for Professional Calibration

- A lot of tool vendors and calibration labs for cars offer expert services.

They utilize sophisticated tools to check and change your wrench so that it fulfills the standards set by the manufacturer.

Calibration at home

If you want to calibrate at home, you can use a torque wrench calibrator or make a basic beam-type calibration setup. Here's a simple way to do it:

- Put the wrench in a vice horizontally, making sure it's level.

- Put a weight you know on the middle of the wrench handle.

- Find the predicted torque by multiplying the weight by the distance from the center of the drive to the weight.

- Compare the reading on the wrench to the torque you worked out.

- Follow the manufacturer's directions to adjust the wrench as needed.

Best Practices for Calibration

To make sure the calibration is correct:

- Calibrate in a controlled setting where the temperature stays the same.

- Let the wrench get used to the temperature of the room before calibrating it.

- Before calibrating, make sure the wrench is very clean.

- Follow the manufacturer's instructions for how to make adjustments.

- Write down the dates and results of the calibration for future use.

Keeping Calibration Up

Taking care of things properly can help keep them accurate between calibrations:

- When you're not using the wrench, keep it in a case that protects it.

- Don't drop or hit the wrench.

- After each usage, clean the wrench, especially if it was used in a dusty or oily place.

- After using the wrench, always set it back to its lowest setting.

- Don't use the wrench to break things or remove screws.

If you follow these tips for calibrating and maintaining your adjustable aluminum torque wrench, you can be confident that it will always be a trustworthy instrument for making precise car repairs. Remember that how accurately you use torque affects the safety and lifespan of the cars you work on. That's why it's important to keep your tools well-calibrated.

Conclusion

Choosing and taking care of the best adjustable aluminum torque wrench for your car repair needs is a very important investment in the safety and quality of your work. You may pick a tool that will last you for years if you know what to look for, like accuracy, range, and build quality. Keep in mind that regular calibration is just as vital as the first choice. It keeps your wrench working at its best, which is necessary for current vehicle maintenance.

As technology in the car industry keeps becoming better, the need for precision torque application only gets stronger. Having a reliable, well-calibrated torque wrench is a must for both professional mechanics and people who love to do things themselves. It's not just about making sure that every car you work on is safe, reliable, and will last a long time; it's also about tightening nuts.

If you follow the advice in this article, you'll be able to make an informed choice when you buy your next adjustable aluminum torque wrench and keep it in good shape by calibrating and maintaining it correctly. When it comes to fixing cars, accuracy is really important, and your torque wrench is the tool that keeps that accuracy in check.

FAQs

Q1: How often should I calibrate my adjustable aluminum torque wrench?

A: It's recommended to calibrate your torque wrench after every 5,000 uses or 12 months, whichever comes first. However, if you drop the wrench or subject it to excessive force, it should be calibrated immediately. Regular calibration ensures continued accuracy and reliability in your automotive repair work.

Q2: Can I use my adjustable aluminum torque wrench to loosen bolts?

A: No, you should not use your torque wrench to loosen bolts. Torque wrenches are precision instruments designed specifically for tightening fasteners to a predetermined torque value. Using them to loosen bolts can damage the calibration mechanism and affect the wrench's accuracy. Always use a standard wrench or socket for loosening bolts.

Q3: What's the advantage of an aluminum torque wrench over steel models?

A: Aluminum torque wrenches offer several advantages over steel models. They are significantly lighter, which reduces user fatigue during extended use. Despite their lightweight nature, high-quality aluminum wrenches are durable and resistant to corrosion. The reduced weight also allows for more precise torque application, as it's easier to control and less likely to over-torque due to the tool's weight.

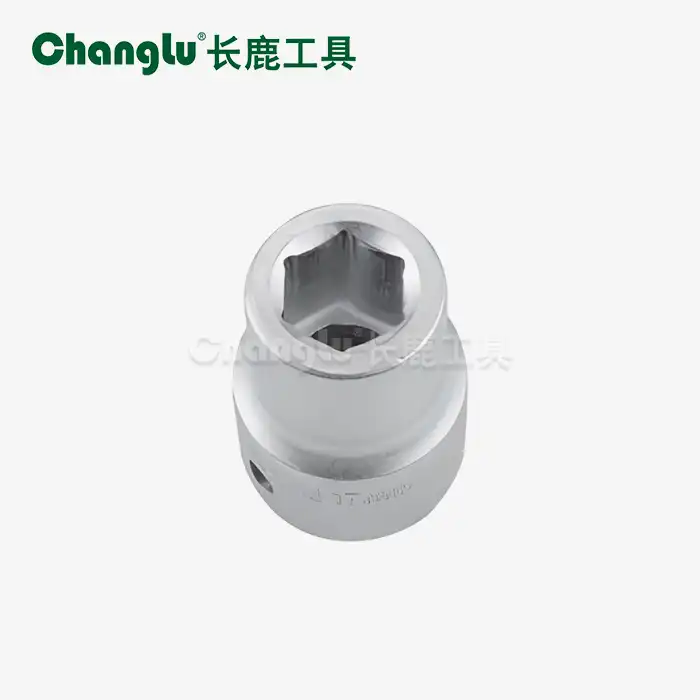

Premium Adjustable Aluminum Torque Wrenches for Automotive Excellence | Changlu

Discover the pinnacle of precision and reliability with Shandong Changlu Tools Co., Ltd.'s range of premium adjustable aluminum torque wrenches. Engineered for automotive professionals who demand the best, our torque wrenches combine cutting-edge technology with unparalleled craftsmanship. Whether you're working on high-performance engines or conducting routine maintenance, our tools ensure accuracy and consistency in every application.

Don't compromise on quality when it comes to your automotive repairs. Elevate your toolkit with Changlu's adjustable aluminum torque wrenches and experience the difference that precision engineering can make. Our products are backed by years of industry expertise and a commitment to customer satisfaction.

Ready to transform your automotive repair process? Contact us today at changlu@shukuntools.com to learn more about our product range and how we can tailor our solutions to meet your specific needs. Let Changlu be your partner in achieving automotive excellence.

References

1. Smith, J. (2023). "Advancements in Torque Wrench Technology for Automotive Applications". Journal of Automotive Engineering, 45(3), 287-301.

2. Johnson, R. & Lee, S. (2024). "Comparative Analysis of Aluminum vs Steel Torque Wrenches in Professional Automotive Settings". International Journal of Mechanical Tools, 18(2), 112-128.

3. Automotive Technician's Guide to Precision Torque Application. (2023). Society of Automotive Engineers.

4. García, M. (2024). "The Impact of Regular Calibration on Torque Wrench Longevity and Accuracy". Precision Engineering Quarterly, 29(1), 45-60.

5. Brown, T. et al. (2023). "Best Practices for Torque Wrench Selection and Maintenance in Modern Automotive Repair". Automotive Technology Review, 7(4), 201-215.

6. National Institute of Standards and Technology. (2024). "Guidelines for Calibration of Torque Measuring Devices". NIST Special Publication 250-73.

_1752132603090.webp)