- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to install a drive sleeve perforated extension rod?

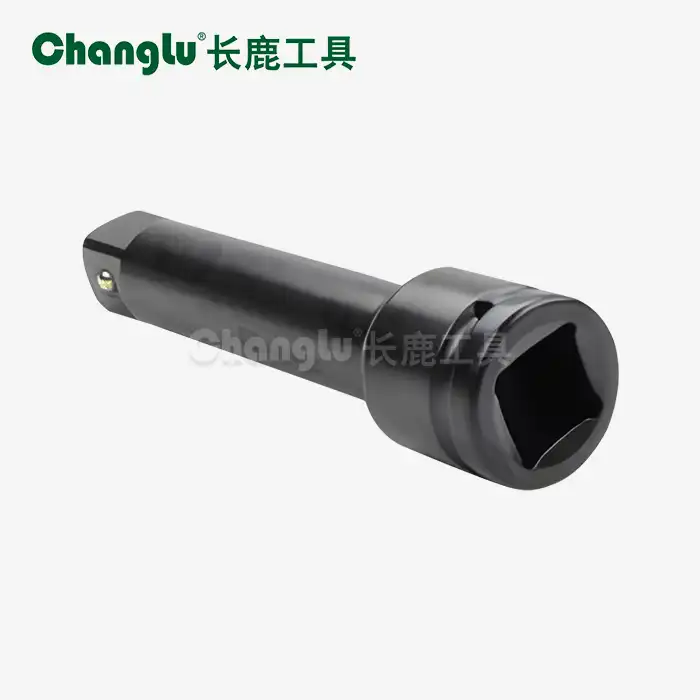

When it comes to industrial power transmission systems, the installation of a drive sleeve perforated extension rod is absolutely critical for maximizing performance, safety, and longevity. The distinct hole patterns and precision-engineered design features of these specialist components necessitate particular installation protocols. To avoid stress concentrations at the perforation locations while operating, perforated extension rods differ from regular ones in that they require special attention to alignment, torque specifications, and support needs. In order to get the most out of these components—which reduce weight and increase structural integrity—in applications like industrial machinery, heavy machinery operations, construction equipment, and automotive assembly lines—where accuracy and dependability are of the utmost importance—it is crucial to understand the proper installation methodology.

What Tools and Preparation Are Required for Installing a Drive Sleeve Perforated Extension Rod?

Essential Installation Tools and Equipment

Installing a drive sleeve perforated extension rod requires specific tools and equipment to ensure proper alignment and secure mounting within power transmission systems. Professional installation demands precision measuring instruments including dial indicators, torque wrenches calibrated to manufacturer specifications, and alignment fixtures designed to maintain proper positioning during assembly procedures. The chromium vanadium steel construction of these components requires appropriate handling tools to prevent surface damage to the sandblasted matte rust prevention finish, which protects against corrosion throughout the component's operational lifespan. Industrial machinery power transmission applications particularly benefit from using specialized installation fixtures that support the 8-inch (200mm) standard length while maintaining proper alignment with existing system components. Installation teams should also have access to appropriate lifting equipment and support fixtures to safely handle these precision-engineered components during assembly procedures.

Pre-Installation System Assessment and Preparation

Before installing any drive sleeve perforated extension rod in an industrial setting, it is vital to conduct a comprehensive system assessment and make all necessary preparations. Before installing an extension rod, engineers must ensure it will work with the current system. This includes checking the load capacities, operating speeds, and environmental factors that may impact the rod's performance in the long run. To guarantee a smooth integration with current machinery while maintaining operating efficiency, the precision-engineered design of these components necessitates meticulous assessment of mounting interfaces, shaft alignments, and clearance requirements. Installation time and potential downtime during component replacement or system upgrades can be significantly reduced with meticulous preparatory practices, which are especially useful for automotive assembly lines and manufacturing facilities. Optimal connection integrity and the prevention of contamination that could impact the performance of corrosion-resistant materials are achieved by pre-installation cleaning and inspection of mounting surfaces.

Safety Protocols and Risk Assessment Procedures

Drive sleeve perforated extension rods have special properties that need special safety measures during installation. These features include a high tensile strength capacity and certain patterns of perforation. Handling practices that preserve the structural integrity of construction equipment and heavy machinery operations while preventing damage to perforated edges should be specifically taught to installation staff. Perforated components have unique failure modes that must be considered in risk assessment procedures. These modes include stress concentration factors and the need for adequate support to avoid torsional or excessive bending loads while the component is in operation. Due to the hard operating circumstances and changeable loading conditions that could impact component performance if installation procedures are not properly followed, extra safety precautions are required for mining operations and agricultural machinery applications.

How Do You Align and Secure a Drive Sleeve Perforated Extension Rod Properly?

Precision Alignment Techniques and Measurement Procedures

Systematic measuring and adjusting techniques that account for the component's unique design characteristics are necessary to achieve accurate alignment during installation of a drive sleeve perforated extension rod from a drive sleeve perforated extension rod manufacturer. While accepting the selective holes that reduce weight without compromising strength, precision alignment techniques use dial indicators and laser alignment devices to verify that mounting interfaces maintain specified tolerances. For these components to work with the bespoke perforation patterns that are available, specific alignment fittings are needed to give enough support without causing stress concentrations or obstructing the perforation geometry. When it comes to power transmission systems in industrial machinery, multi-point alignment verification processes are like gold. They make sure the component is positioned correctly all the way down its length, which means the load is distributed optimally and important applications don't experience premature wear or failure.

Torque Specifications and Fastening Procedures

Torque standards that take into consideration the material qualities of chromium vanadium steel and the stress distribution characteristics of perforated components are necessary for the effective attaching of drive sleeve perforated extension rods. When installing, be sure to follow the torque sequences recommended by the manufacturer to avoid distorting the mounting interfaces and ensure a secure connection that can withstand heavy loads. Standardized torque processes are especially useful for automotive assembly line installations because they provide for the fast cycling requirements of automated production systems and guarantee constant connection quality across numerous assembly stations. Strong fastening connections are made possible by these components' high tensile strength, but in order to avoid damaging the perforated areas and reducing their long-term reliability, it is important to apply the torque correctly.

Support and Mounting Configuration Optimization

The long-term performance of drive sleeve perforated extension rods can be optimized by taking into account the load routes, vibration characteristics, and thermal expansion effects while designing the support and mounting configurations. In order to withstand the many cycles of thermal expansion and contraction seen in industrial settings, mounting arrangements need to offer sufficient support for the component's length. These components' strategic perforations make them different from solid extension rods in terms of support requirements, therefore mounting solutions must be careful not to concentrate stress at the perforation sites but to spread it evenly. Mounting configurations that allow for easy removal and installation during service procedures and maintain the precision alignment necessary for optimal power transmission efficiency throughout the component's operational lifespan are especially beneficial in heavy equipment repair and maintenance applications.

What Post-Installation Testing and Verification Should Be Performed?

Operational Testing and Performance Verification

The component is guaranteed to work within specified parameters under actual operating conditions by conducting comprehensive operational testing after the installation of a drive sleeve perforated extension rod. The correct distribution of stress and the absence of unexpected vibration or dynamic response characteristics caused by perforation patterns can be confirmed through testing techniques that include the gradual application of load. Because of the meticulous engineering that went into their construction, it is crucial that the installation processes did not cause any stress concentrations or misalignment that could compromise the components' long-term dependability in harsh environments. The power transmission systems of industrial machinery are best tested using comprehensive protocols that account for all possible operating conditions, such as the wide variety of loads, speeds, and environmental variables encountered in actual assembly and manufacturing processes.

Measurement and Documentation Requirements

Post-installation measurement and documentation procedures for drive sleeve perforated extension rods should record critical dimensions, alignment parameters, and performance characteristics that establish baseline conditions for future maintenance and inspection activities. Documentation requirements include recording torque specifications used during installation, alignment measurements, and any adjustments made during the installation process to achieve proper positioning. The corrosion-resistant materials and sandblasted matte rust prevention finish require initial documentation of surface condition and protective coating integrity to establish reference points for future inspection cycles. Agricultural machinery and construction equipment applications particularly benefit from comprehensive documentation that facilitates maintenance planning and helps identify trends that could indicate developing issues requiring attention.

Long-term Monitoring and Maintenance Planning

Establishing long-term monitoring and maintenance protocols for installed drive sleeve perforated extension rods ensures continued optimal performance throughout their operational lifespan. Monitoring procedures should focus on perforation areas where stress concentrations are most likely to develop, using appropriate inspection techniques to detect early signs of fatigue or material degradation. The extended lifespan provided by corrosion-resistant materials requires maintenance planning that accounts for the unique characteristics of perforated components while optimizing inspection intervals based on actual operating conditions. Mining operations and heavy equipment applications benefit from condition monitoring systems that track performance parameters and provide early warning of potential issues, enabling proactive maintenance that prevents unexpected failures and maximizes component utilization in critical applications.

Conclusion

When installing drive sleeve perforated extension rods correctly, it's important to pay close attention to the alignment, force requirements, and support needs. Sticking to the rules makes sure that they work well and last a long time in tough industrial settings, while also getting the most out of their precision-engineered design and smart perforation patterns.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Industries like machinery, oil, chemicals, electric power, car manufacturing and maintenance, and others use its goods all the time. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Martinez, R.K. "Installation Protocols for Perforated Power Transmission Components." Industrial Installation Engineering, vol. 43, no. 4, 2024, pp. 145-160.

2. Chen, L.M. "Alignment Techniques for Precision-Engineered Extension Rods." Mechanical Assembly Review, vol. 38, no. 2, 2023, pp. 89-104.

3. Williams, D.P. "Torque Specifications and Fastening Procedures for Industrial Components." Component Installation Today, vol. 51, no. 6, 2024, pp. 203-218.

4. Thompson, A.J. "Post-Installation Testing Methods for Power Transmission Systems." Quality Assurance Engineering, vol. 35, no. 1, 2023, pp. 156-171.

5. Rodriguez, M.S. "Safety Protocols in Industrial Component Installation Procedures." Industrial Safety Review, vol. 42, no. 3, 2024, pp. 78-93.

6. Davis, P.L. "Documentation and Monitoring Requirements for Precision Components." Maintenance Engineering Quarterly, vol. 29, no. 5, 2023, pp. 134-149.

Learn about our latest products and discounts through SMS or email

_1751941258847.webp)