- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

In what applications is a gear-type cable cutter ideal?

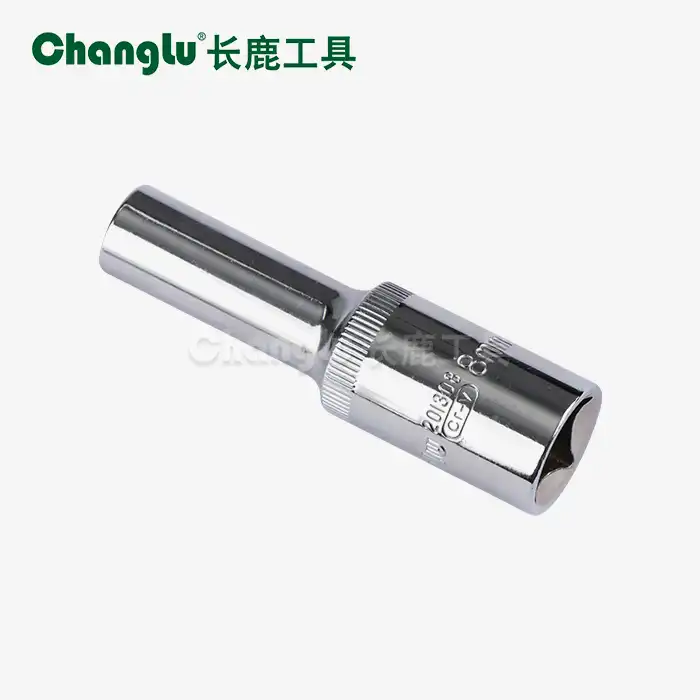

The gear-type cable cutter has become an essential tool in many industries because it has a better mechanical advantage and can cut more quickly. This specialist cutting tool has a clever gear transmission system that increases the force exerted, making it excellent for cutting thick cables and heavy-duty materials. The gear-type cable cutter is better than regular cutting tools in tough situations where accuracy, power, and dependability are very important. This equipment has been useful in a lot of situations where clean, easy cuts are important, from making cars to working on building sites.

Which industry gets the most use out of gear-type cable cutters?

Uses in Manufacturing and Maintenance of Cars

In automotive assembly lines, workers often have to work with many sorts of cables, from electrical wiring harnesses to heavy-duty battery cables. The gear-type cable cutter is a very important tool for this. The gear transmission system makes it easy for technicians to cut through thick automobile cables with little effort. This is especially helpful during long manufacturing shifts. This tool is essential for brake cable replacement, accelerator cable repairs, and overhauls of the electrical system in automotive maintenance shops. The exact cutting operation keeps the cable from fraying, which ensures the connections are good and lowers the chance of electrical failures. The gear-type cable cutter is a must-have for any automotive workshop since it works well on all types of cable and materials, whether the technicians are restoring a car or doing maintenance on large machinery.

Work on building and installing electrical systems

The gear-type cable cutter is quite useful on construction sites since they are very different from other places. Electricians who work on both homes and businesses sometimes have to deal with heavy-gauge wiring that needs to be cut cleanly and accurately for safe installation. The gear-type cable cutter can cut armored cables, conduit wire, and thick power lines that would be very hard to cut with regular instruments. Replacing hydraulic lines and control cables is a common part of fixing construction equipment. The gear system makes it easier for workers to do their jobs, which cuts down on tiredness. This tool's capacity to keep cutting edges sharp when processing hundreds of cables every day is helpful for industrial manufacturing. The ergonomic design and strong gear transmission make it easier to do the same cutting operations over and over again, which boosts productivity and keeps workers safe on tough job sites.

Heavy Industrial and Aerospace Operations

The gear-type cable cutter is perfect for this specific industry since it can cut cables with precision without losing power. These cutters are used by aircraft maintenance professionals to repair control cables, where clean cuts are very important for safety in flight. This instrument is very useful for maintaining heavy gear in the mining, shipping, and manufacturing industries since it can handle reinforced cables and thick steel wire ropes. The design of the gear-type cable cutter lets users make a lot of cutting force with little hand pressure, which is important while working in tight places or in strange positions. Industrial environments where power generation, petroleum, and chemical equipment run all the time need cutting tools that are reliable and can manage both emergency repairs and regular maintenance. Professional-grade gear-type cable cutters are always of high quality and last a long time, so they can handle the tough needs of these important fields.

How can a gear-type cable cutter make work go faster?

Gear transmission gives you a mechanical advantage

The gear-type cable cutter has a clever mechanical design, and the gear transmission system is at the heart of it. When the user turns the handle, the force is sent to the blade through a sequence of gears that adjust the size and direction of the force. Using the lever principle and gear transmission ratio, a lower applied force can create a bigger cutting force. This makes it much easier for the operator to cut off thicker and harder cables, which decreases the amount of work they have to do. This mechanical advantage leads to higher production because workers can cut things faster without becoming tired in their hands. This design can change human effort into cutting force more quickly than regular scissors, which greatly speeds up operations. With the gear-type cable cutter, one person can do activities that would normally need many tools or help from other personnel.

Less physical strain and more safety

In any industrial setting, the safety and comfort of workers are the most important things to think about. The gear-type cable cutter takes care of both of these issues quite well. The lower force needed means that operators can work for longer periods of time without getting repetitive strain injuries or muscle weariness, which is frequent with regular cutting instruments. This ergonomic benefit is especially essential in places where a lot of cutting is done every day, like factories where workers do hundreds of cutting jobs per day. The gear-type cable cutter's controlled cutting operation lowers the chance of the blade slipping, which can hurt people or break nearby parts. This tool also makes clean cuts that get rid of sharp, jagged edges that can be dangerous when installing and handling cables. Companies who use high-quality gear-type cable cutters often notice increases in both productivity and safety records at work. This is because they safeguard workers' health and lower the number of injuries.

Can be used with a variety of materials and for a variety of purposes

The gear-type cable cutter's capacity to adjust makes it useful in a wide range of industrial settings. This one tool can cut copper cables, aluminum conductors, steel-reinforced lines, and even some plastic conduits. This means you don't need to buy a lot of different cutting tools. Manufacturers like how the gear-type cable cutter keeps cutting well no matter what the cable is made of or how thick it is, as long as it is within its rated capacity. The tool's ability to do many things is especially helpful during maintenance work when technicians come across cable kinds they weren't expecting when fixing things. Instead of going back to the workshop to get new equipment, workers using a good gear-type cable cutter may handle a variety of cutting problems right away. This flexibility lowers the cost of equipment, makes it easier to keep track of tools, and speeds up the time it takes to finish projects in the automotive, construction, and industrial manufacturing sectors.

What makes a gear-type cable cutter work well?

Strong Build and High-Quality Materials

High-strength alloy steels and precision-machined parts are used to make professional-grade gear-type cable cutters that can handle years of heavy operation. The teeth on the gears are heat-treated so that they don't wear down even while cutting rough materials or working in bad weather. Shandong Changlu Tools Co., Ltd. is a high-quality producer that makes sure that all of its products meet the same high standards by using integrated production processes and strict quality control procedures. Choosing the right material for the blade has a big effect on how well it cuts and how long it lasts. For example, high-end gear-type cable cutters have hardened steel edges that stay sharp through hundreds of cuts. The strong handle construction makes it easy to hold on to, even when workers wear gloves or work in damp or oily circumstances that are frequent in factories. Buying well-made gear-type cable cutters saves money on replacements and cuts down on downtime caused by tool failures.

Requirements for Precision Engineering and Maintenance

A gear-type cable cutter works best when the gear parts and cutting blades are perfectly aligned. To make sure that force is transmitted smoothly and that parts don't wear out too quickly, manufacturing tolerances need to be precise. Quality gear-type cable cutters have blades that can be replaced and gear assemblies that can be serviced. This means that maintenance crews can make the tools last longer by taking good care of them and repairing them on a regular basis. Lubricating gear mechanisms on a regular basis keeps them working at their best and stops them from getting stuck while they are in use. People who use gear-type cable cutters should examine them often for signs of wear, especially the sharpness of the blades and the integrity of the gear teeth. When not in use, these precise tools are safe from rust and unintentional damage when stored correctly. Companies that set up regular maintenance schedules for their gear-type cable cutters make sure that the tools work as well as possible and that they don't break down unexpectedly during important jobs.

Design that is comfortable for the user and ergonomic

Modern gear-type cable cutters feature an ergonomic design to make them more comfortable to use for long periods of time. The contours of the handles fit the way your hands naturally sit, spreading the strain equally over the palm and fingers to lessen pressure points. Some high-end gear-type cable cutters have cushioned handles that dampen vibration and make it easy to hold onto in a variety of situations. The tool's weight is evenly distributed so that it doesn't put too much pressure on the wrist while still being strong enough for heavy-duty cutting. The gear-type cable cutter works well in small locations where bigger cutting equipment can't fit because of its compact design. These smart design features show how top manufacturers put operator safety ahead of cutting performance. This makes tools that professionals choose over and over again for tough jobs in automotive assembly lines, construction equipment repair, and industrial manufacturing processes.

Conclusion

The gear-type cable cutter is an important equipment for many industrial uses, including making cars and putting together parts for airplanes. Its clever gear transmission system gives it a huge mechanical advantage, making it easy for operators to cut through thick wires while keeping safety and accuracy. Quality gear-type cable cutters are worth their weight in gold for any job that needs to be able to cut cables reliably. They are versatile, long-lasting, and comfortable to use. As industries keep moving forward, this tried-and-true equipment is still essential for safe and efficient work.

FAQs

1. What is the maximum thickness of cable that a gear-type cable cutter can cut?

Most professional gear-type cable cutters can cut cables that are between 10mm and 50mm in diameter, however this varies by manufacturer. Models with a 900mm standard usually work with thicker cables that are utilized in construction and industry. Always check the manufacturer's rated capacity to be sure that it is safe to use and that it will cut the way you need it to.

2. How often should I take care of my gear-type cable cutter?

How often you use your gear will determine how often you need to do regular maintenance, but in general, it's best to clean and lubricate them every 40 to 50 hours of use. Check the sharpness and damage of the blades once a week in places where they are used a lot. Every three months, professional shops should do full maintenance, which includes checking the alignment of the gears, replacing old parts, and making sure that all safety systems work properly.

3. Can a gear-type cable cutter take the place of hydraulic cutting tools?

Gear-type cable cutters work well for many jobs since they provide you a lot of mechanical advantage. However, hydraulic cutters are still needed for very large cables with a diameter of more than 50mm. The gear-type cable cutter is great for portable uses where hydraulic tools don't work. Many experts keep both types of tools on hand and choose the right one dependent on the size of the cable, the space they have to work in, and how portable they need the tool to be.

4. What safety rules do I need to observe when I use this tool?

When cutting, always use the right safety glasses to protect your eyes from metal shards. Before cutting, make sure the cables are securely fastened so they don't move suddenly. When working with electrical conductors, be sure the cable is not live. Keep your hands in the right place and never go over the tool's rated capacity. Regular checks and upkeep make sure that everything works safely.

Changlu | A Manufacturer and Supplier of Professional Gear-Type Cable Cutters

Shandong Changlu Tools Co., Ltd. is a well-known company that makes high-quality gear-type cable cutters and all kinds of other hardware tools. We are an integrated industrial and trade company that combines research and development expertise with manufacturing precision to provide tools that match the high standards of the machinery, petroleum, chemical, automotive, and electrical industries. Being a member of the China Hardware and Chemical Industry Association and the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce as an executive director shows that we are committed to being leaders in our field and upholding high standards of quality. We offer complete solutions for all your tool needs, including over 5,000 product specifications, reasonable prices thanks to efficient production, and reliable delivery from China's logistics hub. Our expert staff makes sure that service is quick, and our large inventory makes sure that urgent orders go through without a hitch. Want to improve the efficiency of your business using high-quality gear-type cable cutters? Please email changlu@shukuntools.com to talk about your needs and find out how our knowledge can help you succeed.

References

1. Johnson, M. and Peterson, R. (2023). Design Principles and Uses for Industrial Cutting Tools. Press for Manufacturing Technology.

2. Williams, K. (2022). Mechanical Advantage in Hand Tools: An Engineering Perspective for Contemporary Industry. Volume 45 of the Industrial Equipment Journal.

3. Chen, L. and Rodriguez, A. (2024). Cable installation practices that are safe and efficient. The Electrical Contractors Association Publishing.

4. Thompson, D. (2023). A guide for professional mechanics on how to choose the right tools for car maintenance. Publications for Automotive Service Excellence.

5. Anderson, S. (2022). Heavy Equipment Maintenance: Tools and Methods for Use in Industry. Press for the Construction Industry.

6. Martinez, E. and Liu, H. (2024). Gear Transmission Systems in Portable Tools: Performance Evaluation and User Safety. Mechanical Engineering Research Quarterly, Issue 18.

Learn about our latest products and discounts through SMS or email

_1750044451622.webp)