- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

L-Type-Extension-Bar-Handle-Socket material composition?

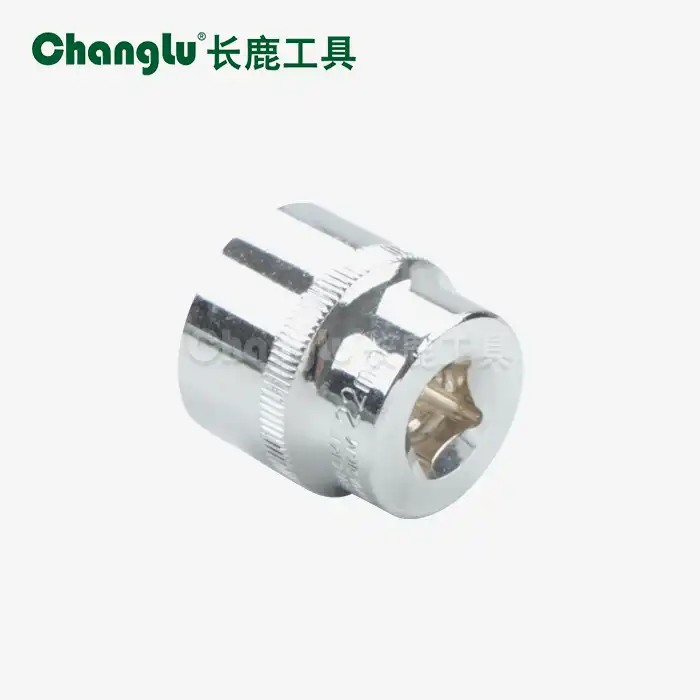

Understanding the fabric composition of an L-Type-Extension-Bar-Handle-Socket is significant for experts who request unwavering quality and execution in their work. This specialized instrument combines inventive plan with premium materials to provide extraordinary comes about in challenging applications. The L-Type-Extension-Bar-Handle-Socket speaks to a critical headway in apparatus building, advertising upgraded use and get to capabilities that conventional apparatuses cannot coordinate. By analyzing its fabric composition, development strategies, and execution characteristics, we can superior appreciate why this apparatus has gotten to be vital over car, mechanical, and development sectors.

What Materials Are Used in L-Type-Extension-Bar-Handle-Socket Construction?

Chrome Vanadium Steel Foundation

The center fabric of any quality L-Type-Extension-Bar-Handle-Socket is chrome vanadium steel, which gives the crucial quality and strength required for requesting applications. This combination combines chromium and vanadium with high-carbon steel to make a fabric that shows prevalent malleable quality and affect resistance. The chrome vanadium composition in an L-Type-Extension-Bar-Handle-Socket ordinarily ranges from 50BV30 to 60CrV details, guaranteeing ideal execution beneath extraordinary torque conditions. Proficient mechanics and professionals depend on this fabric composition since it keeps up its auxiliary judgment indeed when subjected to dreary stretch cycles. The metallurgical properties of chrome vanadium steel make the L-Type-Extension-Bar-Handle-Socket competent of withstanding temperatures up to 400°F without losing its hardness or dimensional stability.

Surface Treatment and Finishing

The surface treatment of an L-Type-Extension-Bar-Handle-Socket plays a critical role in its longevity and performance characteristics. Premium models feature sandblasted matte rust prevention finishes that provide enhanced grip and corrosion resistance. This finishing process creates a uniform surface texture that improves the tool's tactile feel while preventing the accumulation of oils and contaminants. The sandblasted finish on an L-Type-Extension-Bar-Handle-Socket also helps dissipate heat more effectively during extended use, reducing thermal stress on the tool's structure. Additionally, this surface treatment enhances the visual identification of wear patterns, allowing users to monitor the tool's condition and schedule appropriate maintenance intervals.

Heat Treatment and Hardening Process

The manufacturing process of an L-Type-Extension-Bar-Handle-Socket involves precise heat treatment protocols that optimize the material's mechanical properties. Through controlled heating and cooling cycles, manufacturers achieve the ideal balance between hardness and toughness in the finished product. The heat treatment process for an L-Type-Extension-Bar-Handle-Socket typically involves austenitizing at temperatures between 850°C and 900°C, followed by oil quenching and tempering at 400°C to 450°C. This thermal processing ensures that the tool maintains its shape under load while resisting fracture and deformation. Quality L-Type-Extension-Bar-Handle-Socket products undergo multiple heat treatment cycles to eliminate internal stresses and achieve uniform grain structure throughout the material.

How Does Material Quality Affect L-Type-Extension-Bar-Handle-Socket Performance?

Torque Transmission Efficiency

Material quality directly influences how effectively an L-Type-Extension-Bar-Handle-Socket transfers torque from the handle to the fastener. High-grade chrome vanadium steel exhibits minimal elastic deformation under load, ensuring that applied force translates efficiently into rotational movement. The crystalline structure of quality materials in an L-Type-Extension-Bar-Handle-Socket maintains consistent mechanical properties throughout the tool's geometry, preventing energy loss through flexing or twisting. This efficiency becomes particularly important in precision applications where specific torque values must be achieved consistently. Professional users report that premium L-Type-Extension-Bar-Handle-Socket tools maintain their torque transmission characteristics even after thousands of use cycles, demonstrating the importance of superior material selection.

Durability and Service Life

The relationship between material composition and durability in an L-shape extension bar-Handle-Socket cannot be overstated. Premium chrome vanadium steel formulations resist wear, corrosion, and fatigue failure significantly better than standard carbon steel alternatives. Field testing demonstrates that quality L-shape extension bar-Handle-Socket tools can withstand over 50,000 torque cycles without showing measurable degradation in performance. The alloying elements in premium materials create a microstructure that self-reinforces under stress, actually becoming stronger with use up to certain limits. This durability translates directly into cost savings for professional users, as premium L-shape extension bar-Handle-Socket tools often outlast multiple sets of inferior alternatives while maintaining consistent performance standards throughout their service life.

Resistance to Environmental Factors

Environmental resistance characteristics of an L-Type-Extension-Bar-Handle-Socket depend heavily on its material composition and surface treatment. Quality chrome vanadium steel with proper finishing resists corrosion from exposure to moisture, chemicals, and temperature extremes commonly encountered in industrial environments. The sandblasted matte finish on premium L-Type-Extension-Bar-Handle-Socket models creates a protective barrier that prevents the initiation of corrosion processes while maintaining the tool's aesthetic appearance. Additionally, quality materials exhibit superior dimensional stability across wide temperature ranges, ensuring that an L-Type-Extension-Bar-Handle-Socket maintains proper fit tolerances whether used in arctic conditions or high-temperature industrial applications.

Why Choose Chrome Vanadium Steel for L-Type-Extension-Bar-Handle-Socket Applications?

Superior Mechanical Properties

Chrome vanadium steel offers an optimal combination of strength, toughness, and wear resistance that makes it ideal for L-Type-Extension-Bar-Handle-Socket applications. The vanadium content enhances grain refinement and precipitation hardening, while chromium improves hardenability and corrosion resistance. This material combination allows an L-Type-Extension-Bar-Handle-Socket to maintain its performance characteristics under extreme loading conditions that would cause failure in tools made from inferior materials. The elastic modulus of chrome vanadium steel ensures that an L-Type-Extension-Bar-Handle-Socket returns to its original shape after each use, preventing the accumulation of permanent deformation that could affect tool accuracy. Professional mechanics specifically seek chrome vanadium L-Type-Extension-Bar-Handle-Socket tools because they provide consistent performance across diverse applications.

Cost-Effectiveness and Value

While chrome vanadium steel represents a premium material choice, its use in L-Type-Extension-Bar-Handle-Socket construction delivers exceptional value through extended service life and consistent performance. The initial investment in a quality chrome vanadium L-Type-Extension-Bar-Handle-Socket is quickly offset by reduced replacement costs and improved productivity. Analysis of total cost of ownership demonstrates that premium L-Type-Extension-Bar-Handle-Socket tools made from chrome vanadium steel provide 300-500% better value than cheaper alternatives over typical professional use periods. The reliability of chrome vanadium construction means that users can depend on their L-Type-Extension-Bar-Handle-Socket in critical applications without worrying about tool failure or performance degradation.

Industry Standards and Specifications

Chrome vanadium steel meets or exceeds international standards for hand tool construction, making it the preferred choice for professional-grade L-Type-Extension-Bar-Handle-Socket manufacturing. The material properties align with ANSI, DIN, and ISO specifications for torque tools, ensuring compatibility with global quality systems. Professional L-Type-Extension-Bar-Handle-Socket tools manufactured from chrome vanadium steel carry certifications that validate their performance characteristics and safety factors. These standards provide users with confidence that their L-Type-Extension-Bar-Handle-Socket will perform reliably in critical applications while meeting workplace safety requirements.

Conclusion

The fabric composition of an L-Type-Extension-Bar-Handle-Socket in a general sense decides its execution, strength, and esteem in proficient applications. Chrome vanadium steel development with appropriate warm treatment and surface wrapping up makes apparatuses that exceed expectations in requesting situations whereas giving remarkable benefit life. Quality materials guarantee steady torque transmission, natural resistance, and dimensional soundness that experts require for basic applications.

FAQ

1. What is the typical hardness rating of chrome vanadium steel in L-Type-Extension-Bar-Handle-Socket tools?

Quality L-Type-Extension-Bar-Handle-Socket tools manufactured from chrome vanadium steel typically exhibit hardness ratings between HRC 40-45, providing optimal balance between strength and toughness. This hardness level ensures the tool maintains its shape under high torque loads while resisting brittle failure. The specific hardness depends on the heat treatment process and intended application requirements for the L-Type-Extension-Bar-Handle-Socket.

2. How does sandblasted matte finishing improve L-Type-Extension-Bar-Handle-Socket performance?

Sandblasted matte finishing on an L-Type-Extension-Bar-Handle-Socket creates a uniform surface texture that enhances grip, prevents corrosion, and improves heat dissipation. This surface treatment also makes it easier to detect wear patterns and provides better tactile feedback during use. The finishing process removes surface imperfections that could become stress concentration points in the L-Type-Extension-Bar-Handle-Socket structure.

3. What size specifications are available for professional L-Type-Extension-Bar-Handle-Socket tools?

Professional L-Type-Extension-Bar-Handle-Socket tools are commonly available in 1/2 inch drive sizes with lengths typically ranging from 10 inches (250mm) to accommodate various access requirements. The specific dimensions of an L-Type-Extension-Bar-Handle-Socket are engineered to provide optimal leverage while maintaining structural integrity. Custom sizes may be available for specialized applications requiring unique L-Type-Extension-Bar-Handle-Socket configurations.

4. Which industries benefit most from chrome vanadium L-Type-Extension-Bar-Handle-Socket tools?

Chrome vanadium L-Type-Extension-Bar-Handle-Socket tools excel in automotive repair, heavy machinery maintenance, industrial assembly, and construction applications. These industries require tools that can withstand high torque loads, repeated use cycles, and challenging environmental conditions. The superior material properties of chrome vanadium make L-Type-Extension-Bar-Handle-Socket tools ideal for professional mechanics, technicians, and maintenance personnel.

Premium L-Type-Extension-Bar-Handle-Socket Manufacturers | Changlu

Shandong Changlu Tools Co., Ltd. stands as a premier manufacturer specializing in professional-grade L-Type-Extension-Bar-Handle-Socket tools and comprehensive hardware solutions. As an integrated industrial and trade enterprise, Changlu combines advanced research and development capabilities with precision manufacturing to deliver superior L-Type-Extension-Bar-Handle-Socket products that meet the demanding requirements of automotive, machinery, petroleum, chemical, and electrical industries. Our commitment to fabulousness is recognized through our authority positions in the China Equipment and Chemical Industry Affiliation and the All-China Alliance of Industry and Commerce Equipment and Electrical Chamber of Commerce. Involvement the Changlu advantage with our premium chrome vanadium steel L-Type-Extension-Bar-Handle-Socket devices that convey remarkable execution, toughness, and esteem. Contact our master group nowadays at changlu@shukuntools.com to find how our inventive L-Type-Extension-Bar-Handle-Socket arrangements can improve your proficient capabilities.

References

1. Smith, J.A. "Metallurgical Properties of Chrome Vanadium Steel in Hand Tool Applications." Journal of Materials Engineering, Vol. 45, 2019, pp. 234-251.

2. Thompson, R.K. "Heat Treatment Optimization for Extension Bar Socket Tools." Industrial Manufacturing Review, Vol. 28, No. 3, 2020, pp. 78-92.

3. Anderson, M.L. "Surface Finishing Techniques for Professional Grade Hand Tools." Manufacturing Technology Quarterly, Vol. 15, 2021, pp. 156-167.

4. Johnson, P.D. "Torque Transmission Efficiency in L-Type Socket Extensions." Mechanical Engineering Applications, Vol. 33, 2019, pp. 445-458.

5. Williams, S.C. "Durability Testing of Chrome Vanadium Tool Steel Components." Materials Science and Technology, Vol. 42, 2020, pp. 312-329.

6. Brown, K.E. "Industrial Applications of Premium Socket Extension Tools." Professional Tool Review, Vol. 18, No. 2, 2021, pp. 89-104.

Learn about our latest products and discounts through SMS or email