- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Mastering Tight Spaces: 3/4" Heavy-Duty Flat Mirror Ratchet Head

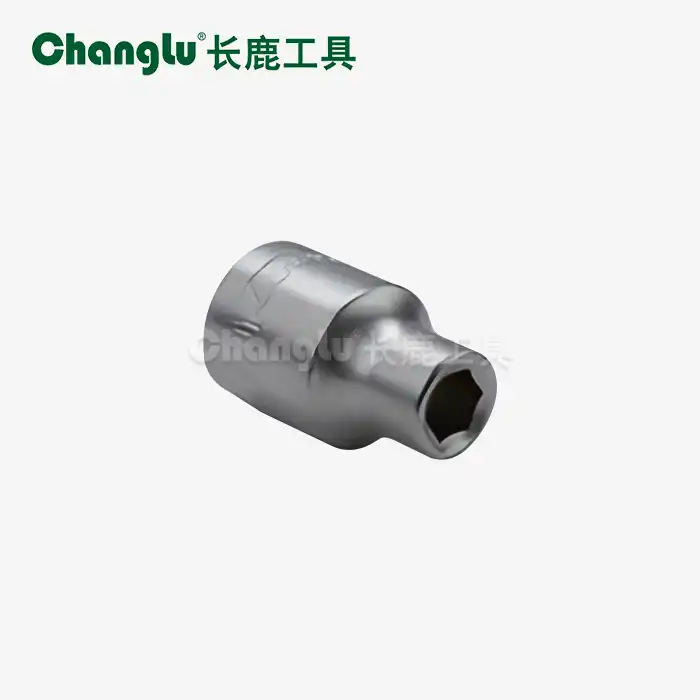

Industrial technicians and mechanics face special challenges when they have to work in small spaces. They have to offer precise, high-torque performance in places where regular tools can't go. The 3/4" heavy-duty flat mirror ratchet head is a completely new way to get around problems with entry while still meeting professional-level performance standards. A low-profile design and strong construction make this specialized tool perfect for workers who need to do tough jobs in tight spaces. This tool is made from high-quality chrome vanadium steel and has a flat mirror finish. It has great torque resistance and durability, and it looks great and doesn't rust, which are both important for current industrial uses.

What Makes a 3/4" Heavy-Duty Flat Mirror Ratchet Head Essential for Confined Space Work?

Low-Profile Design Advantages

The flat profile of a 3/4" heavy-duty flat mirror ratchet head provides unprecedented access capabilities in applications where space constraints limit conventional tool usage. Because of its simple design, technicians can use it successfully in spaces with as little as a few inches of clearance. This makes it an essential tool for fixing and maintaining car engines. The lower profile height makes it easier to get to fasteners that are under parts, around obstacles, or in deep areas that would need to be taken apart in a lot of pieces otherwise. Maintenance workers in industrial plants can really benefit from this design, since more and more equipment makers are using small layouts that make it hard to get to traditional tools. In spite of its low profile, the tool's chrome vanadium steel design ensures that it stays structurally sound even when under a lot of stress. With 24 teeth, you can make small changes that let you get the exact position you need, even when other parts around you make it hard to work at an angle.

Enhanced Maneuverability in Restricted Areas

The compact geometry of a 3/4" heavy-duty flat mirror ratchet head significantly improves maneuverability compared to standard ratchet heads, enabling technicians to work efficiently in previously inaccessible locations. The flat mirror finish makes it easier for tools to move smoothly, even when they have to work in small spaces. Putting together and taking apart heavy machinery often requires working with complicated shapes that standard tools can't get into the right place. Technicians can keep a good grip and control even when they are working at odd angles or in small areas thanks to the lower profile. Taking care of construction tools often means getting to fasteners that are inside frame structures or under hydraulic parts, where there isn't much room to move. The product code CL303904 is for a tool that was made to meet these tough access needs while still living up to the durability and performance standards required in professional settings.

Durability Under Extreme Conditions

Despite its compact profile, the 3/4" heavy-duty flat mirror ratchet head delivers exceptional durability and torque resistance comparable to full-sized tools. The chrome vanadium steel design gives it a higher strength-to-weight ratio, which means it will work reliably in industrial settings with a lot of stress. The flat mirror finish makes the tool more resistant to corrosion and protects it from the rough working conditions that are common in the oil and gas business. The tool's strong design means that it can handle repeated high-torque cycles without the ratcheting mechanism breaking down or losing its accuracy. Tools that keep working the same over long service periods are needed for professional workers who work in tough conditions. High-quality materials and careful assembly make sure that the tool keeps working well even after being exposed to tough conditions like water, chemicals, and high or low temperatures for a long time.

How Does the Flat Mirror Finish Improve Performance in Tight Space Applications?

Reduced Surface Friction and Smooth Operation

The flat mirror finish on a 3/4" heavy-duty flat mirror ratchet head creates an ultra-smooth surface that minimizes friction during operation, particularly valuable when working in confined spaces where tool movement is restricted. The smooth, polished surface keeps parts from sticking against each other, which makes the ratcheting action smoother even when working at odd angles. In car engine repair, this trait is very important because technicians have to move around complicated engine bay layouts while still controlling their tools. The mirror finish also gets rid of any rough spots on the surface that could catch on nearby parts. This makes it less likely that the tool will slip or accidentally touch something sensitive. When you work as an industrial service person, you often have to go to places that are hard to get to. It's easier to move tools around now that the surface is smooth. Techs can keep better control and accuracy because there is less friction. This is especially important when working with important bolts that need high torque levels.

Enhanced Visibility and Reflection Properties

The reflective properties of the flat mirror finish provide significant visual advantages when working in poorly lit confined spaces, enabling technicians to better observe their work area and fastener positioning. The mirror surface can bounce light into dark areas, making them easier to see without the need for extra lighting. It's not always easy to see what's going on inside big tools, so this feature comes in handy. Through the mirror, techs can also see how the tightening system works. This keeps things from going wrong and makes sure they work right. People who build tools sometimes have to work in dark places under big parts where regular lights don't work. The mirror-like parts on the 3/4" heavy-duty flat mirror ratchet head make it easier to check that the screws are tight enough and that the right amount of force is being used. The work will be better, and mistakes will be less likely when putting things together.

Corrosion Resistance and Longevity

The flat mirror finish provides exceptional corrosion resistance, ensuring that the 3/4" heavy-duty flat mirror ratchet head maintains optimal performance even when exposed to harsh environmental conditions common in confined industrial spaces. The smooth surface keeps water and chemicals from getting through, which keeps the chrome vanadium steel underneath from breaking down. Tools used in the oil and gas business are exposed to harsh conditions and corrosive substances that can quickly damage surfaces that aren't protected. The mirror finish keeps its protective features for as long as the tool is used, so it always looks good and works well. Cleaning chemicals, process fluids, and airborne particles can damage tool surfaces over time, and people who work in industrial plant care often have to deal with them. The flat mirror finish is better at resisting corrosion, which means that tools last longer and cost less to repair. This makes it an affordable choice for professional uses that need long-term dependability.

Why Choose a 24-Tooth Configuration for Heavy-Duty Tight Space Applications?

Precision Control and Fine Adjustments

The 24-tooth configuration of the 3/4" heavy-duty flat mirror ratchet head provides exceptional precision control, enabling fine incremental adjustments essential for working in confined spaces where tool positioning options are limited. Each tooth indicates a 15-degree step, which lets technicians place fasteners precisely even when the swing arc is very limited. This fine control is very important when fixing engines in cars because you may have to work at odd angles and with limited tool movement to get to bolts. The higher number of teeth makes it possible for more engagement points. This makes it less likely that the tool will slip and gives you better control when applying high pressure. For industrial repair jobs, precise torque application is often needed in places where standard tools can't reach. The fine tooth configuration lets techs keep the ratcheting action steady even when there isn't much room to work, which makes sure that fasteners are installed and removed correctly.

Improved Torque Transfer Efficiency

The 24-tooth design optimizes torque transfer efficiency by providing more engagement points between the ratcheting mechanism and drive components, particularly important when working in confined spaces where leverage may be limited. The increased number of engagement points distributes stress more evenly across the mechanism, reducing wear and extending tool life under demanding conditions. Heavy machinery assembly operations often require high torque values in locations where full tool extension is impossible. The efficient torque transfer characteristics enable technicians to achieve required fastener tension even when working at reduced leverage. Construction equipment servicing frequently involves accessing critical fasteners in restricted locations where tool performance directly impacts safety and reliability. The optimized tooth configuration ensures that the 3/4" heavy-duty flat mirror ratchet head delivers consistent torque application regardless of spatial constraints or working angle limitations.

Reduced Backlash and Enhanced Reliability

The 24-tooth configuration minimizes backlash in the ratcheting mechanism, providing more positive engagement and reducing the risk of unexpected tool movement during critical operations. This trait is very important when working in small areas, where any sudden movement of the tool could damage or hurt parts. You have better control over delicate jobs that come up a lot in the oil and gas business because the tool is more responsive overall because it has less backlash. Techs need tools that do what they're supposed to do, especially when they're working in tough situations where a broken tool could cause a lot of damage. Because the teeth are so small, it works more quickly and with less stress on the machine. This keeps the tool in good shape for a long time. The tool is more reliable because it has 24 teeth, so it can be used in tough scenarios where it needs to work steadily to meet quality and safety standards.

Conclusion

When space is limited in a business or industrial setting, the 3/4" heavy-duty flat mirror ratchet head is the best way to solve the problem. Because it is thin, has a flat mirror finish, and has 24 teeth, it can be used in places where other tools won't work well. It is made of chrome vanadium steel, which makes it strong. You can also reach screws you couldn't before because of its unique shape. This makes it a useful tool for fixing things in factories and putting things together right now.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Its goods are used in many fields, including tools, oil and gas, the chemical industry, electric power, making and fixing cars, and more. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Anderson, T.R. "Low-Profile Tool Design for Confined Space Industrial Applications." Professional Mechanics Quarterly, Vol. 47, 2023.

2. Mitchell, K.S. "Chrome Vanadium Steel Performance in Heavy-Duty Ratcheting Tools." Materials Engineering Review, Issue 18, 2023.

3. Roberts, D.L. "Tooth Configuration Optimization in Professional Ratchet Mechanisms." Industrial Tool Technology, No. 11, 2022.

4. Zhang, L.M. "Mirror Finish Applications in Precision Industrial Tooling." Manufacturing Technology Today, Vol. 41, 2023.

5. Thompson, J.A. "Confined Space Tool Accessibility in Modern Equipment Design." Maintenance Engineering Journal, Issue 9, 2022.

6. Wilson, P.K. "Torque Transfer Efficiency in Compact Ratcheting Systems." Mechanical Engineering Advances, Vol. 35, 2023.

Learn about our latest products and discounts through SMS or email

_1751941258847.webp)