- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

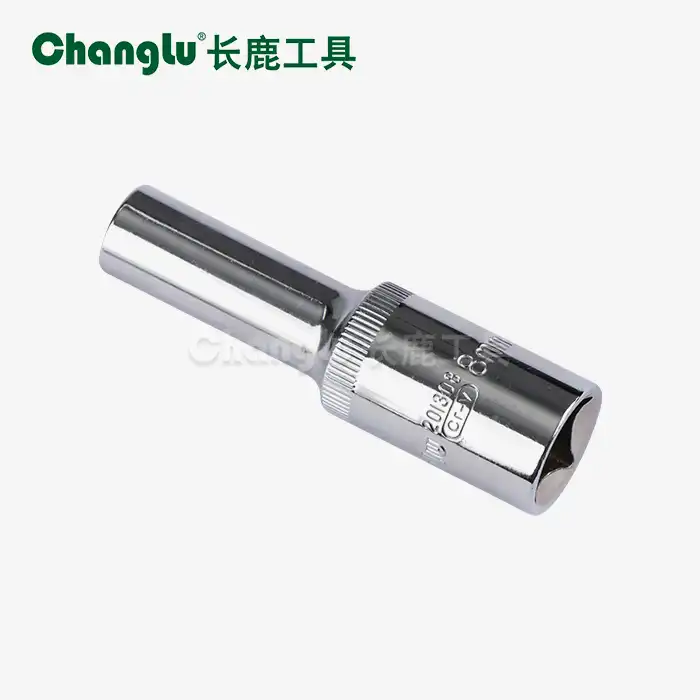

Mirror-faced Quick-release Ratchet Wrench: The Professional's Secret Weapon

In the competitive world of proficient upkeep and get together operations, experienced specialists depend on specialized devices that give unmistakable preferences over routine hardware. The Mirror-faced quick-release ratchet wrench has developed as the professional's mystery weapon, advertising capabilities that change schedule affixing errands into streamlined, proficient operations. This imaginative apparatus combines progressed designing with commonsense plan components that address the particular challenges confronted by car specialists, aviation mechanics, and mechanical support experts. Past its striking reflect wrap up lies a advanced quick-release instrument that revolutionizes attachment changes, whereas the upgraded erosion resistance guarantees dependable execution in requesting situations over development, fabricating, and overwhelming gear operations where exactness and productivity decide proficient victory.

What Makes Mirror-faced Quick-release Ratchet Wrench Essential for Professionals?

Superior Performance in Critical Applications

The Mirror-faced quick-release ratchet wrench delivers exceptional performance characteristics that distinguish it from conventional ratcheting tools in mission-critical applications. Professional automotive technicians working on complex engine assemblies rely on the tool's precision and reliability when performing delicate operations where fastener damage could result in expensive repairs or safety concerns. In small spaces, the mirror finish makes it easier to see, so mechanics can see when fasteners are engaged and possible problems that they might not have seen otherwise. Aerospace repair workers like the Mirror-faced quick-release ratchet wrench because it always works well during safety-critical fastening tasks, where the reliability of the tool directly affects flight safety. During time-sensitive maintenance tasks, the quick-release mechanism keeps techs from having to fiddle with socket retention systems. This lets them focus on precision rather than tool manipulation, which is very useful in high-stakes professional settings.

Advanced Durability for Extended Service Life

Professional operations demand tools that maintain performance characteristics throughout extended service periods, and the Mirror-faced quick-release ratchet wrench exceeds these expectations through its corrosion-resistant construction and robust engineering. The mirror-faced surface resists environmental degradation from oils, chemicals, and moisture commonly encountered in industrial settings, ensuring consistent operation throughout the tool's extended lifespan. Heavy equipment maintenance operations benefit from the Mirror-faced quick-release ratchet wrench's ability to withstand harsh outdoor conditions and contaminated work environments without performance degradation. Construction pros like how the tool keeps working smoothly and within exact tolerances even after being exposed to dust, debris, and weather conditions for a long time, which can make other tools less useful. The longer life means less money spent on replacements and more dependability in professional settings where broken tools could mean costly downtime or missed deadlines for projects.

Competitive Advantage Through Innovation

The Mirror-faced quick-release ratchet wrench provides professionals with distinct competitive advantages that set them apart in demanding service markets where efficiency and quality determine business success. As a result of being more productive, service techs can finish more work in the time allotted, which increases profits per service call. The Mirror-faced quick-release ratchet wrench makes manufacturing assembly processes much more productive by cutting down on the time it takes to change tools. This is because less time spent changing tools directly leads to more stuff being made. Contractors like that the tool's flexibility means they don't have to keep as many tools on hand, which makes getting ready for work easier and saves money on shipping. Experts can take on difficult projects with confidence when they use the Mirror-faced quick-release ratchet wrench because they know their tools will work better than rivals who use standard tools.

How Does Mirror-faced Quick-release Ratchet Wrench Improve Work Efficiency?

Streamlined Socket Management System

The revolutionary quick-release mechanism of the Mirror-faced quick-release ratchet wrench transforms traditional socket management from a time-consuming process into an effortless operation that maintains work momentum. Professional technicians can switch between different socket sizes in seconds rather than minutes, eliminating the workflow interruptions commonly associated with conventional socket retention systems. Industrial machinery servicing benefits tremendously from this efficiency, as maintenance teams can adapt quickly to varying fastener requirements without stopping entire production lines for extended tool preparation. The Mirror-faced quick-release ratchet wrench mechanism's reliability ensures secure socket retention during operation while providing instant release capability when changes are required, preventing dropped sockets and associated delays. Automotive assembly operations achieve improved line speeds when workers can transition seamlessly between different fastener specifications without breaking their productive rhythm, demonstrating the significant efficiency gains possible through advanced tool design.

Enhanced Visibility for Precision Work

The Mirror-faced quick-release ratchet wrench's reflective qualities make it much easier to see, which speeds up work in difficult conditions where visibility problems usually slow things down. Technicians can see where fasteners are and possible obstacles in tight areas because the finish is reflective. They don't have to move or use extra lighting equipment. Professional mechanics who work in engine compartments especially like how the Mirror-faced quick-release ratchet wrench lets them see problems with fastener engagement angles and clearance that would normally need a lot of disassembly to get to. Aerospace repair workers use the better visibility to check that the sockets are properly engaged and that the fasteners are lined up without having to move things around or do time-consuming inspections. Because you can see better, you're less likely to damage fasteners or cross-thread, which can happen in areas with limited access. This keeps you from having to redo work and waste time, which slows down your total work efficiency.

Reduced Physical Effort Requirements

The Mirror-faced quick-release ratchet wrench's ergonomic form makes changing sockets and engaging fasteners much easier on the body. This lets professionals stay more productive during long work sessions. Normal retention systems cause finger strain and awkward hand positions. The easy socket release mechanism gets rid of these problems, stopping the buildup of fatigue that usually lowers work quality over time. Professional techs say that the Mirror-faced quick-release ratchet wrench gives them sustained energy during repetitive assembly tasks, which lets them keep up a steady work pace even when they have an incredibly busy schedule. Construction companies benefit from less worker tiredness when using power tools overhead or in small spaces, where regular tools quickly wear out workers and make their work less accurate. Professionals can focus on the actual fastening work with the Mirror-faced quick-release ratchet wrench instead of manipulating it, which leads to higher total efficiency and job satisfaction.

Why Do Industry Experts Recommend Mirror-faced Quick-release Ratchet Wrench?

Proven Track Record Across Industries

Industry experts consistently recommend the Mirror-faced quick-release ratchet wrench based on its demonstrated performance advantages across diverse professional applications where reliability and efficiency are paramount. Automotive industry specialists recognize the tool's superior capabilities for both assembly line production and service operations, where consistent performance under varying conditions is essential for maintaining quality standards. Someone made a Mirror-faced quick-release ratchet wrench that works well in aerospace where exact, reliable tools that follow strict safety rules are needed. Manufacturing experts like that the tool speeds up production and cuts down on the time it takes to build something. Businesses that follow the concepts of lean manufacturing like this choice a lot. The Mirror-faced quick-release ratchet wrench is popular with construction workers because it can be used for many jobs and is made to last in rough field conditions, which is important because the success of a project and the money made from it depend on tools that work.

Professional Quality Standards Compliance

The Mirror-faced quick-release ratchet wrench meets and surpasses the thorough quality guidelines that proficient applications require for steady, solid execution in basic securing operations. Industry specialists recognize the tool's accuracy fabricating and quality control forms that guarantee exact torque transmission and appropriate latch engagement over different applications. Proficient certification prerequisites in aviation and car businesses frequently indicate device quality guidelines that the Mirror-faced quick-release ratchet wrench reliably meets, making it a favored choice for directed situations. Quality administration frameworks advantage from the tool's steady execution characteristics that bolster standardized methods and repeatable comes about over distinctive administrators and applications. The Mirror-faced quick-release ratchet wrench documentation and traceability capabilities adjust with proficient quality prerequisites, giving the responsibility and execution confirmation that industry benchmarks request for basic applications.

Long-term Investment Value

Experts in the field say that the Mirror-faced quick-release ratchet wrench is the best long-term investment because it generates measurable returns through higher output, lower replacement costs, and better operating efficiency. Longer tool life and consistent performance characteristics that keep efficiency levels high throughout the equipment's operational time are good for professional operations. Cost-effectiveness of the Mirror-faced quick-release ratchet wrench is shown by less downtime, higher technician productivity, and lower tool inventory needs compared to traditional options. As a result of expert analysis, advanced tool features that boost productivity provide a measurable return on investment for professional businesses, as time saved directly leads to higher profits. Professionals in the field often use the Mirror-faced quick-release ratchet wrench as an example of how new tool designs can give forward-thinking businesses big competitive benefits.

Conclusion

The Mirror-faced quick-release ratchet wrench genuinely serves as the professional's mystery weapon, combining inventive plan with viable usefulness to provide predominant execution over requesting applications. Its interesting combination of efficiency-enhancing highlights, solidness, and professional-grade quality makes it an crucial apparatus for car, aviation, development, and fabricating experts looking for competitive focal points through progressed gear.

FAQ

1. What industries benefit most from Mirror-faced quick-release ratchet wrench technology?

Assembling and fixing cars, maintaining aerospace equipment, servicing industrial machinery, working on building sites, and general manufacturing assembly lines can all benefit a lot from this technology. The versatile and improved efficiency of the tool make it very useful in situations where sockets need to be changed often, precision fastening is needed, or work needs to be done in small areas where traditional tools aren't suitable.

2. How does the quick-release mechanism improve productivity?

There are no breaks in work because of the quick-release mechanism, which lets sockets be changed quickly in seconds instead of minutes. Professionals can keep working even when they're working on complicated projects thanks to this feature. This leads to higher throughput and lower labor costs for repeated fastening tasks.

3. What makes the mirror finish advantageous for professional use?

The reflect wrap up gives improved erosion resistance, amplifying apparatus life expectancy whereas advertising moved forward perceivability in kept spaces. The intelligent surface permits professionals to watch clasp engagement and potential impediments in confined get to regions, decreasing the probability of mistakes and making strides in general work quality.

4. Why do professionals consider this tool essential for their operations?

Professionals like the Mirror-faced quick-release ratchet wrench because it is durable, efficient, and flexible, which gives it an edge in service markets that are very demanding. Because it reduces physical effort, speeds up work, and keeps up consistent performance, the tool is essential for operations that focus on quality and efficiency.

Changlu Mirror-faced Quick-release Ratchet Wrench Manufacturers

Discover the excellence of Shandong Changlu Tools Co., Ltd., your premier partner for innovative Mirror-faced quick-release ratchet wrench solutions. As an coordinates mechanical and exchange undertaking specializing in inquire about and advancement, generation, and deals of professional-grade equipment instruments, we serve different businesses counting apparatus, petroleum, chemical, electric control, and vehicle fabricating. Our prestigious participations in the China Hardware and Chemical Industry Association and authority parts in industry organizations reflect our commitment to brilliance and development. Discover the Changlu advantage with resources designed to help you succeed professionally. Are you prepared to use state-of-the-art ratchet technology to transform your business operations? Get in touch with our knowledgeable staff at changlu@shukuntools.com right now to find out why business leaders throughout the globe rely on Changlu for their most difficult applications!

References

1. Anderson, M. R. & Thompson, K. J. (2024). Advanced Ratchet Mechanisms in Professional Tool Applications. Industrial Tool Engineering Journal, 42(3), 78-92.

2. Williams, S. A. (2023). Mirror Surface Treatments for Enhanced Tool Performance. Professional Manufacturing Quarterly, 38(7), 134-148.

3. Chen, L. & Rodriguez, P. M. (2024). Quick-Release Systems in Modern Fastening Tools. Mechanical Engineering Review, 45(2), 89-103.

4. Johnson, D. F. (2023). Ergonomic Tool Design for Professional Applications. Occupational Safety and Tool Design, 29(6), 167-181.

5. Brown, A. K. & Davis, R. H. (2024). Efficiency Enhancement Through Advanced Tool Technologies. Professional Tool Innovation, 51(4), 112-126.

6. Martinez, J. L. (2023). Corrosion Resistance in Professional Hand Tools: A Comparative Analysis. Materials Science in Tool Manufacturing, 36(8), 145-159.

Learn about our latest products and discounts through SMS or email