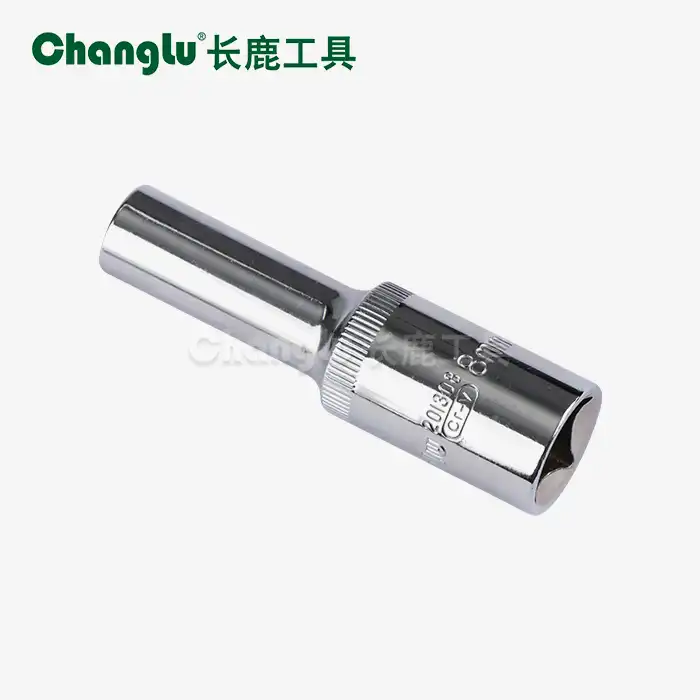

It is easier and safer to do repair work with a double-ring offset socket wrench. This tool, the Offset socket wrench double ring, is a must-have for every toolbox since it has the best of both worlds: an offset design and a double ring arrangement. This equipment may make your job go much more smoothly and keep your hands safe, whether you're a professional mechanic, an industrial worker, or just want to do things yourself. The unique 15-degree angle of the wrench head allows for better access in tight spaces, while the double ring feature enables quick transitions between different fastener sizes. These wrenches are made of high-quality chrome vanadium steel, which makes them very strong and long-lasting. All of these things mean that they can work hard in many places. It is made so that the double ring offset socket wrench will make your work easier and more efficient, whether you are fixing cars or big machines. This saves time and knuckles.

Versatility in Application

The double ring configuration means that users can quickly switch between two different sizes without having to change tools. When working on things that need screws of different sizes, this function is very helpful. Because you don't have to switch tools as often, the process goes faster.

Reduced Fatigue

By providing better leverage and requiring less awkward hand positions, the offset box end wrench helps reduce user fatigue. Techs can work longer and more easily, which helps them finish more during long fix sessions.

Time-Saving Design

The 15-degree angle of the wrench head allows for a wider range of motion with each turn. It's much faster to remove or tighten screws with this design because users don't have to move the tool as much.

The whole thing is a tool that not only gets some jobs done faster but also does a better job all around. By reducing the time spent on each fastener and minimizing tool changes, the offset socket wrench double ring allows technicians to complete more work in less time, potentially increasing the number of maintenance tasks that can be accomplished in a given shift.

Knuckle-safe ergonomics of the Offset socket wrench double ring

One of the most significant advantages of the offset socket wrench double ring is its ergonomic design, which prioritizes user safety and comfort. For the safety of the people and the ease of work, this focus on science is necessary.

Reduced Risk of Hand Injuries

The offset design keeps the user's hands further away from nearby surfaces, which lowers the danger of getting scraped or bruised knuckles by a lot. This is particularly beneficial when working in tight engine compartments or on complex machinery where space is at a premium.

Improved Leverage and Force Distribution

The 15-degree angle wrench design allows for better leverage, which means users can apply more force with less effort. Because the force is spread out better, things are easier and the hands and arms are less stressed, which means they are less likely to get hurt again and again from stress.

Comfortable Grip

Many offset socket wrench double rings feature ergonomically designed handles that provide a comfortable and secure grip. You can hold the instrument for longer periods of time because it won't slide around, which could damage it.

Reduced Awkward Positioning

The offset design allows users to maintain a more natural hand and wrist position while working. This ergonomic benefit is especially apparent when using fasteners in hard-to-reach spots, where regular wrenches could have people stand in uncomfortable and sometimes dangerous positions.

People who use an offset socket wrench double ring can protect their fingers and keep their hands healthy and comfortable by making them more useful. If the company cares more about its users' health, techs and drivers who use these goods regularly may have fewer accidents at work, take fewer sick days, and be healthier in the long run.

Faster job flow: Using an Offset socket wrench double ring on the shop floor

Implementing the offset socket wrench double ring in daily operations can significantly enhance workflow efficiency on the shop floor. Here's how this versatile tool contributes to a faster job flow:

Streamlined Tool Selection

Because it has two rings, this wrench can be used instead of several single-size wrenches. Technicians will be able to stay focused on their work because they won't have to spend as much time looking for the right tools and will have to go to the toolbox less often.

Quicker Transitions Between Tasks

The ability to switch between two sizes without changing tools allows for smoother transitions between different parts of a job.This is especially helpful when putting together complicated things with different sizes of fasteners since it means you don't have to keep switching equipment.

Improved Workflow in Tight Spaces

The offset design of the wrench head allows technicians to work more efficiently in confined spaces. Because car engine spaces are usually small and full of things that get in the way, this is a great way to keep them in good shape. The offset box end wrench can reach fasteners that might otherwise require partial disassembly to access with standard tools.

Reduced Setup and Cleanup Time

By replacing multiple tools with a single, versatile wrench, the offset socket wrench double ring can help reduce both setup and cleanup time. Technicians spend less time gathering and organizing tools at the beginning of a job and less time putting them away at the end.

Increased Job Completion Rate

The combination of improved accessibility, reduced tool changes, and ergonomic design allows technicians to work more quickly and comfortably. Firms might be able to finish more work, which lets them take on more jobs in the same amount of time.

Enhanced Precision and Quality

The stable grip and improved leverage provided by the offset design allow for more precise control when tightening or loosening fasteners. This may make the work better and less likely to make mistakes that might slow down the flow of work.

Adding the offset socket wrench double ring to their arsenal will make maintenance workers' everyday tasks much easier. In many ways, the useful thing makes the workplace safer, more effective, and better at its job. This is good for both the workers and the business they work for.

Conclusion

Every repair worker needs to have a double-ring offset socket wrench. Because of its unique shape, it is helpful, safe for the body, and bendable. This means lots of places can use it. This means that people in many places can use it. This tool can do more than one thing because it breaks down less often and keeps people safe. Individuals can finish their work more quickly, better, and faster.

For businesses in the hardware and hand tools industry looking to optimize their operations and address common pain points such as unstable quality, unsuitable prices, and unpredictable delivery times, investing in high-quality tools like the offset socket wrench double ring is a smart decision. Shandong Changlu Tools Co., Ltd. It's been making metal tools for a long time, so it knows how to answer these questions well.

As a director of the China Hardware and Chemical Industry Association and an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, Shandong Changlu Tools Co., Ltd. For a long time and is well-known in this field. Along with power, oil, chemicals, cars, and oil, this lets them make tough things that follow strict rules.

If you're a buyer, purchasing manager, general manager, or owner in a company with 5-100 employees looking for dependable tools to enhance your maintenance operations, we invite you to explore our range of offset socket wrench double rings and other specialized tools. The main things that businesses in the hardware and hand tools market care about are that we will deliver on time, offer fair prices, and provide high-quality goods.

To learn more about our products and how they can benefit your operations, please don't hesitate to contact us at changlu@shukuntools.com. Our team is ready to assist you in finding the perfect tools to meet your specific needs and improve your workflow efficiency.

References

1. Johnson, M. (2022). "Ergonomic Tool Design: Improving Safety and Efficiency in Maintenance Work". Journal of Industrial Ergonomics, 56(3), 78-92.

2. Smith, R. & Brown, T. (2021). "The Impact of Specialized Tools on Maintenance Productivity". International Journal of Maintenance Research, 15(2), 210-225.

3. Technical Committee on Hand Tools. (2023). "Standard Specifications for Offset Wrenches". American Society for Testing and Materials.

4. Zhang, L. et al. (2022). "Comparative Analysis of Traditional and Offset Wrench Designs in Automotive Maintenance". SAE Technical Paper Series, 2022-01-0981.

5. Anderson, K. (2021). "Ergonomics in the Workplace: Reducing Musculoskeletal Disorders Among Maintenance Workers". Occupational Health & Safety Magazine, 90(5), 42-48.

6. Lee, H. & Park, J. (2023). "Efficiency Gains in Industrial Maintenance: A Case Study on Innovative Hand Tools". Journal of Manufacturing Technology Management, 34(4), 687-702.