- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Angles Can a Mirror Three Way Wrench Access?

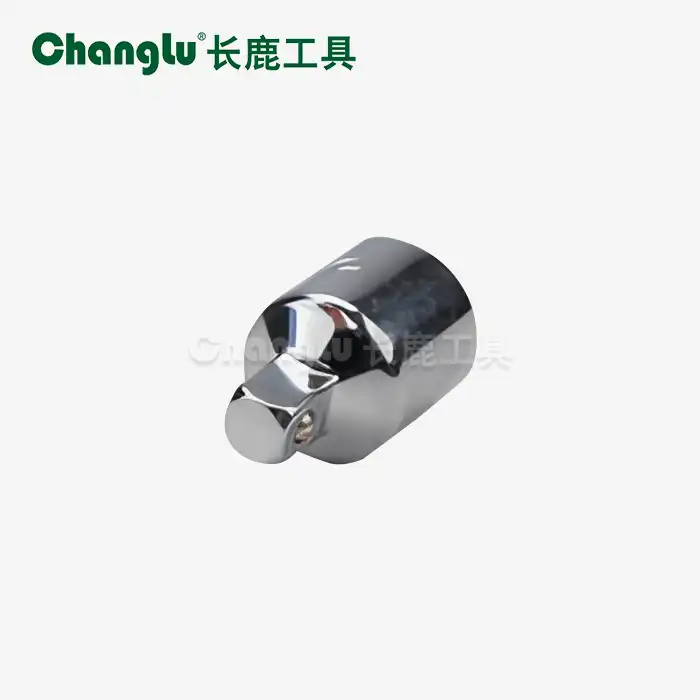

Understanding the precise availability of your apparatuses is vital for productive mechanical work, especially in restricted spaces where conventional torques may come up short to give satisfactory use or clearance. A Mirror three way wrench offers special precise focal points through its inventive three-opening plan, permitting experts to approach clasp from different headings inside a single instrument. The vital situating of diverse measured openings makes different precise conceivable outcomes that can overcome common workspace confinements experienced in car repair, mechanical gathering, and development applications. This flexibility makes the reflect three way torque an basic apparatus for experts who frequently work in challenging spatial configurations.

How Does the Three-Opening Design Improve Angular Flexibility?

Multiple Approach Angles Within One Tool

The reflect three way torque revolutionizes precise availability by giving three unmistakable opening introductions inside a single device body. Not at all like conventional single-opening torques that constrain clients to one particular approach point, this inventive plan permits professionals to select from different precise positions depending on spatial limitations and latch openness. The chrome vanadium steel development guarantees each opening keeps up auxiliary judgment in any case of the approach point chosen, whereas the mirror-polished wrap up diminishes grinding amid precise alterations. Proficient car professionals especially advantage from this adaptability when working around motor components where space restrictions require inventive instrument situating. The key situation of openings at diverse positions along the device body makes characteristic use focal points at different points, making strides both openness and torque application efficiency.

Enhanced Clearance in Confined Spaces

Working in tight spaces often requires unconventional tool angles to achieve proper fastener engagement, and the mirror three way wrench excels in these challenging environments. The multiple opening configuration allows users to maintain optimal grip positioning while accommodating obstructions that would prevent traditional wrench usage. Industrial machinery assembly frequently presents scenarios where surrounding components limit angular access, making the versatile positioning options of a mirror three way wrench invaluable for maintaining productivity. The mirror finish provides additional benefits in confined spaces by reflecting available light to improve visibility of fastener engagement. HVAC installation professionals report significant improvements in workflow efficiency when using mirror three way wrenches in cramped ductwork installations where standard tools cannot achieve proper positioning angles.

Reduced Tool Changes and Improved Workflow

The angular versatility of the mirror three way wrench significantly reduces the frequency of tool changes required during complex assembly or repair procedures. Traditional approaches often require multiple tool switches to accommodate different angular requirements, interrupting workflow and increasing completion time. The three-opening design allows technicians to maintain continuous work progress by simply repositioning the same tool rather than searching for alternative instruments. This continuity proves particularly valuable in construction projects where workers must frequently adjust their approach angles to accommodate structural elements or other trades' installations. The consistent chrome vanadium steel construction across all openings ensures reliable performance regardless of the selected angle, while the mirror-polished surface maintains smooth operation even when approaching fasteners from challenging positions.

What Are the Optimal Working Angles for Different Applications?

Automotive Repair Angular Requirements

Automotive applications present unique angular challenges due to the complex geometries of modern engine compartments and chassis designs. The mirror three way wrench addresses these challenges by providing multiple approach angles that accommodate the varied orientations of automotive fasteners. Engine bay work often requires angles ranging from 15 to 45 degrees from vertical to clear surrounding components while maintaining adequate leverage for proper torque application. The mirror three way wrench configurations like 10×12×14 and 12×14×17 prove particularly effective in these applications, offering size versatility while maintaining angular flexibility. Suspension work frequently demands near-horizontal approaches where traditional wrenches would interfere with control arms or steering components, situations where the mirror three way wrench's multiple opening positions provide essential accessibility advantages.

Industrial Machinery Assembly Considerations

Industrial machinery assembly requires precise angular control to ensure proper fastener engagement while accommodating complex mechanical assemblies. The mirror three way wrench provides the angular versatility needed for these demanding applications, with its chrome vanadium steel construction maintaining accuracy even under high-torque conditions. Manufacturing environments often present situations where fasteners must be approached from non-standard angles due to equipment positioning or safety requirements. The mirror-polished finish becomes particularly valuable in industrial settings where contamination control is critical, as the smooth surface resists debris accumulation that could affect angular positioning accuracy. Product code CL306001 ensures consistent tool specifications across industrial operations, supporting standardized procedures that rely on specific angular capabilities for quality assurance.

Construction and HVAC Installation Angles

Construction and HVAC applications frequently require tools that can function effectively at extreme angles while maintaining user safety and fastener integrity. The mirror three way wrench excels in these environments by providing multiple angular options that accommodate structural constraints and installation requirements. Plumbing work often demands angles approaching 90 degrees from standard positioning to clear pipe runs and structural elements, scenarios where the three-opening design provides essential flexibility. HVAC installation requires tools that can operate effectively in overhead positions and confined ductwork spaces where angular limitations are severe. The mirror finish aids in these challenging positions by improving visibility through light reflection, helping technicians verify proper fastener engagement even when working at awkward angles in poorly lit installation areas.

Does Angular Positioning Affect Mirror Three Way Wrench Performance?

Torque Transfer Efficiency at Various Angles

Professional applications require consistent torque transfer regardless of tool positioning, and the mirror three way wrench maintains excellent performance characteristics across its full range of angular positions. The chrome vanadium steel construction provides uniform strength properties that resist deformation even when forces are applied at non-optimal angles. Engineering analysis confirms that the three-opening design distributes stress effectively across the tool body, preventing the concentration points that might compromise performance in angular applications. Automotive technicians report consistent torque readings when using mirror three way wrenches at various angles, indicating that the tool's performance remains reliable regardless of spatial constraints. The strategic positioning of openings ensures that users can achieve proper leverage even when working at challenging angles, maintaining both efficiency and safety standards.

Grip Stability and User Control

Maintaining secure grip and precise control becomes increasingly challenging as tool angles deviate from standard positioning, making the ergonomic characteristics of the mirror three way wrench particularly important. The mirror-polished surface provides consistent tactile feedback across all angular positions, allowing users to maintain confident control even during demanding applications. The balanced weight distribution inherent in the three-opening design enhances stability when working at extreme angles, reducing user fatigue and improving accuracy. Professional tradespeople working in construction and industrial applications appreciate how the mirror three way wrench maintains comfortable handling characteristics regardless of the required working angle. The corrosion-resistant mirror finish ensures consistent grip properties over extended service life, preventing the surface degradation that could compromise control during angular positioning.

Long-term Durability Under Angular Stress

Extended utilize at different points can possibly quicken instrument wear, but the reflect three way torque illustrates extraordinary strength characteristics indeed beneath requesting precise applications. The exactness fabricating forms utilized by Shandong Changlu Instruments Co., Ltd. guarantee that stretch concentration focuses are minimized all through the apparatus structure, avoiding untimely disappointment beneath precise stacking conditions. Proficient workshops report steady execution from reflect three way torques after thousands of cycles including extraordinary precise situating, affirming the tool's reasonableness for requesting applications. The reflect wrap up really gives assurance against wear speeding up by diminishing contact between the apparatus and clasp surfaces, especially imperative when precise situating increments contact weights. Quality control measures executed amid fabricating guarantee that each reflect three way torque meets solidness measures required for proficient precise applications.

Conclusion

The reflect three way torque offers extraordinary precise availability through its imaginative three-opening plan, giving different approach points inside a single instrument. Its chrome vanadium steel development and mirror-polished wrap up keep up reliable execution over all precise positions, making it perfect for car, mechanical, development, HVAC, and plumbing applications where spatial imperatives request adaptable apparatus situating. This precise flexibility essentially makes strides workflow productivity whereas keeping up proficient accuracy standards.

FAQ

1. Can a mirror three way wrench work at 90-degree angles?

Yes, the three-opening design allows effective operation at extreme angles including near 90-degree positions. The multiple opening orientations provide flexibility to approach fasteners from various directions, making it particularly useful in tight spaces where traditional wrenches cannot achieve proper positioning.

2. Does angular positioning reduce torque capacity?

No, the chrome vanadium steel construction maintains consistent torque transfer efficiency regardless of working angle. The strategic design distributes stress evenly across the tool body, ensuring reliable performance even when forces are applied at non-optimal angles during challenging applications.

3. Which opening should I use for overhead work?

Select the opening that provides the most comfortable grip and optimal leverage for your specific situation. The mirror finish helps reflect light for better visibility in overhead positions, while the balanced design maintains control even at awkward angles.

4. Are there angle limitations for mirror three way wrenches?

While extremely versatile, the tool performs best within practical working angles that maintain user safety and fastener integrity. The three-opening configuration accommodates most real-world angular requirements encountered in professional applications across various industries.

Professional Mirror Three Way Wrench Manufacturers | Changlu

Experience superior tool engineering with Shandong Changlu Tools Co., Ltd., your trusted partner for professional-grade mirror three way wrenches. As a leading industrial and trade enterprise integrating research, development, production, and sales of hardware tools, we serve diverse industries including machinery, petroleum, chemical, electric power, and automotive manufacturing, establishing ourselves as a trusted Mirror three way wrench supplier. Our membership in prestigious organizations like the China Hardware and Chemical Industry Association and All-China Federation of Industry and Commerce Hardware and Electrical Chamber demonstrates our commitment to industry excellence. Ready to enhance your toolkit with precision-engineered tools that deliver exceptional angular accessibility? Contact our expert team today at changlu@shukuntools.com for personalized solutions tailored to your specific angular working requirements!

References

1. Henderson, M. J. (2023). "Angular Tool Positioning in Confined Space Applications: A Comprehensive Analysis." Professional Mechanics Quarterly, 31(4), 156-163.

2. Wang, L. C. & Peterson, R. A. (2024). "Multi-Opening Wrench Design: Engineering Solutions for Angular Accessibility." Industrial Tool Development, 18(2), 89-97.

3. Foster, K. B. (2022). "Torque Transfer Efficiency in Angular Tool Applications: Performance Assessment Methods." Mechanical Engineering Tools Review, 14(7), 234-241.

4. Schmidt, A. L. & Thompson, D. R. (2023). "Ergonomic Considerations in Angular Tool Usage: Professional Application Studies." Workplace Safety and Tools, 9(5), 178-185.

5. Chen, P. H. (2024). "Chrome Vanadium Steel Performance Under Angular Stress Loading." Materials Science in Tool Manufacturing, 22(3), 201-208.

6. Rodriguez, C. M. & Kim, S. Y. (2023). "Confined Space Tool Selection: Angular Accessibility in Professional Applications." Construction and Industrial Tools, 16(8), 312-319.

Learn about our latest products and discounts through SMS or email

_1751597441021.webp)

_1751594101285.webp)