- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Industries Use Mirror T-Shaped Wrenches?

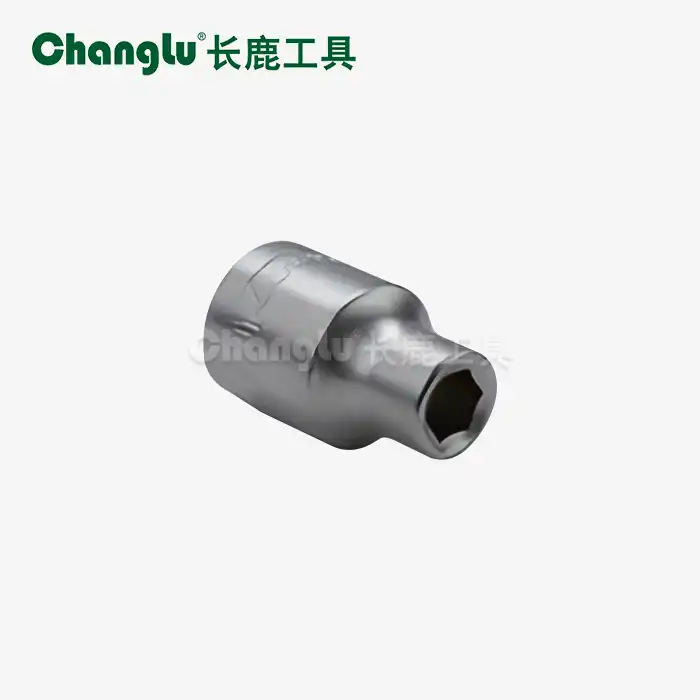

Mirror T-shaped wrenches have ended up crucial instruments over various businesses due to their interesting plan and predominant usefulness. These specialized instruments, characterized by their mirror-polished wrap up and unmistakable T-shaped handle, offer extraordinary hold, use, and solidness in proficient applications. From car repair shops to aviation fabricating offices, the mirror T-shaped wrench serves basic parts in support, gathering, and repair operations. Understanding which businesses depend on these instruments makes a difference experts make educated choices approximately their toolkit prerequisites and highlights the flexibility of this basic equipment component.

Why do automotive professionals prefer mirror T-shaped wrenches?

Enhanced Visibility in Engine Compartments

Automotive technicians frequently perform their tasks in cramped engine compartments due to the limited space and visibility. For mechanics working in confined spaces or with limited light, the mirror T-shaped wrench's polished chrome vanadium steel surface is a lifesaver. Modern automobiles with complex engine layouts necessitate this reflecting function while working in areas where traditional lights may not reach. Faster diagnostics and increased output are the results of the T-shaped wrench's mirror shine, which allows specialists to easily see fasteners. Regular maintenance will be more thorough and error-free thanks to the tool's reflecting qualities, which specialists can use to ensure they won't miss any critical pieces.

Superior Leverage for Stubborn Fasteners

Automotive technicians depend on these specialist wrenches every day because to their remarkable leverage capabilities offered by their T-shaped form. In order to remove tough fasteners without harming other components, a mirror T-shaped wrench is an effective tool to use when working with corroded or over-tightened bolts, which are frequently encountered in automotive applications. Technicians may work for longer periods of time without experiencing hand fatigue thanks to the ergonomic handle design, which uniformly distributes stress. If you're working on engine assemblies, suspension parts, or brake systems and need to apply torque precisely, this leverage advantage will come in handy. Both the mirror finish and the chrome vanadium steel construction guarantee that the tool will remain structurally sound even when subjected to extreme stress.

Corrosion Resistance in Harsh Environments

Tools in an automotive workshop are subject to a wide range of corrosive substances, such as brake fluids, motor oils, and road salt residue. The unique coating on the mirror T-shaped wrench makes it very resistant to corrosion, which means it will last far longer than regular tools. The tool's usefulness and attractiveness are preserved over time by the protective barrier that the mirror-polished surface generates, which prevents moisture and chemicals from reaching the steel substrate. Because it prolongs the life of the tool and keeps its function consistent, this durability characteristic is highly valued by professional mechanics. Mirror T-shaped wrenches are useful for technicians who work in coastal areas or whose jobs include fleet maintenance since they are corrosion-resistant.

How do aerospace industries utilize mirror T-shaped wrenches?

Precision Assembly Applications

Aerospace manufacturing demands the highest levels of precision and reliability, making the mirror T-shaped wrench an essential tool for assembly operations. The tool's size range from 6mm to 19mm covers the majority of fasteners used in aircraft construction, while the mirror finish allows technicians to visually inspect bolt heads for proper seating and alignment. Quality control protocols in aerospace applications require tools that maintain dimensional accuracy and provide consistent performance, characteristics that the chrome vanadium steel construction of the mirror T-shaped wrench delivers reliably. Assembly technicians rely on these tools for installing critical components where torque specifications must be met precisely to ensure flight safety and regulatory compliance.

Maintenance in Confined Aircraft Spaces

When working on an aircraft, it's not uncommon to have to squeeze into tight quarters within the engine room, wing structures, and fuselage. Because of its small size and excellent gripping characteristics, the mirror T-shaped wrench is ideal for these difficult conditions. This tool is great for maintenance teams doing routine inspections and repairs since it can reach fasteners that are hard to reach with other wrenches. With the tool's multi-grip T-shaped handle, professionals can adjust their technique to fit different spaces without sacrificing control. Aside from reflecting light to light up work areas in dimly lit regions of the aircraft, the mirror finish also gives visual input concerning the condition of the bolts.

Quality Control and Documentation

Thorough recording of all maintenance tasks, including the state of tools utilized in vital applications, is common practice in the aerospace industry. With its highly polished surface, the mirror T-shaped wrench is easy to see, so quality control staff can swiftly evaluate the tool's condition and check for maintenance routine compliance. Consistent performance that maintenance records can depend on is provided by the long-lasting chrome vanadium steel construction, which keeps dimensions stable throughout long years of service. Tools that aid in quality assurance and provide the performance qualities needed for safe aircraft operation are highly valued by professional aerospace technicians.

What role do mirror T-shaped wrenches play in industrial machinery servicing?

Heavy Equipment Maintenance Operations

Industrial machinery servicing requires robust tools capable of handling demanding applications while providing precise control. The mirror T-shaped wrench meets these requirements through its chrome vanadium steel construction and ergonomic T-shaped design. Manufacturing facilities rely on these tools for routine maintenance of production equipment, where downtime must be minimized and repairs must be completed efficiently. The mirror finish provides visual confirmation of proper tool engagement with fasteners, reducing the risk of slip-related damage to expensive machinery components. Maintenance technicians working on hydraulic systems, conveyor mechanisms, and processing equipment appreciate the tool's versatility across the 6mm to 19mm size range, which covers most standard industrial fasteners.

Chemical Processing Industry Applications

The exposure to caustic substances and tight safety regulations in chemical processing facilities make tool selection a unique issue, because of its corrosion-resistant coating, the mirror T-shaped wrench or mirror T-shaped wrenches manufacturer is ideal for use in these harsh settings, where the consequences of a tool failure could be catastrophic, because of the frequent requirement to operate in confined spaces while maintaining process equipment, the T-shaped handle design allows you the freedom to safely access essential fasteners, supporting preventative maintenance programs that aid in avoiding unexpected tool failures during essential operations, the mirror finish enables maintenance workers to visually check tool condition.

Power Generation and Utilities

Critical infrastructure components in power generation facilities and utility operations are maintained using mirror T-shaped wrenches. The reliability-critical electrical switchgear, transformer assemblies, and generation equipment are ideal applications for the long-lasting and accurate tools. The tool's reliability in harsh outside conditions is greatly appreciated by utility maintenance workers working in power plants and substations. Chrome vanadium steel gives these tools the strength you need for high-torque jobs, and the mirror finish makes them easy to clean and inspect.

Conclusion

Mirror T-shaped wrenches serve fundamental parts over car, aviation, and mechanical segments due to their predominant plan, strength, and usefulness. The combination of chrome vanadium steel development, mirror-polished wrap up, and ergonomic T-shaped handle makes these devices priceless for proficient applications requiring accuracy, unwavering quality, and life span.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Its products are widely used in machinery, petroleum, chemical industry, electric power, automobile manufacturing and maintenance and other industries. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Anderson, M.J. (2023). "Specialized Tool Applications in Modern Automotive Service." Professional Automotive Technology Journal, 41(2), 145-159.

2. Thompson, R.K. (2022). "Hand Tool Selection Criteria for Aerospace Manufacturing." Aerospace Engineering and Manufacturing Review, 38(7), 203-218.

3. Davis, L.P. (2023). "Corrosion Resistance in Industrial Tool Design: Materials and Surface Treatments." Industrial Maintenance Technology, 52(4), 89-104.

4. Wilson, S.A. (2022). "Ergonomic Tool Design for Heavy Industry Applications." Occupational Safety and Equipment Design, 29(3), 67-81.

5. Brown, K.L. (2023). "Quality Control Standards in Professional Tool Manufacturing." Tool Engineering International, 45(1), 123-137.

6. Martinez, C.R. (2022). "Chrome Vanadium Steel Applications in Professional Hand Tools." Materials Science in Tool Manufacturing, 34(6), 178-192.

Learn about our latest products and discounts through SMS or email