- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What makes a mirror-finish L‑type wrench durable and corrosion‑resistant?

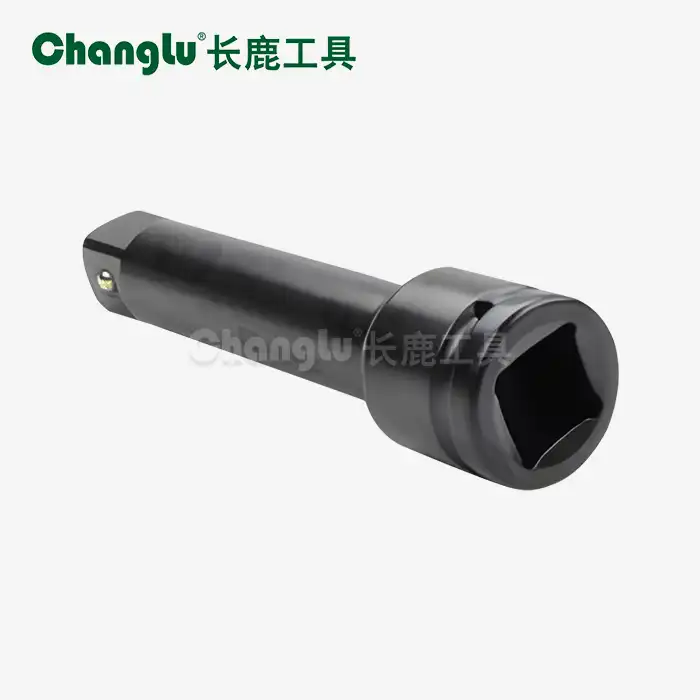

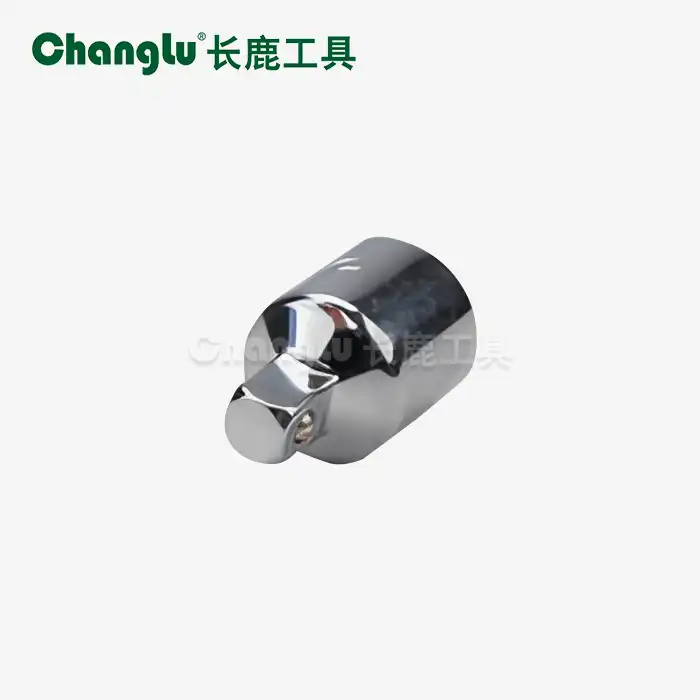

The Mirror L type wrench stands as a testament to precision engineering and advanced metallurgy, combining exceptional durability with superior corrosion resistance. This professional-grade tool achieves its remarkable performance through a sophisticated combination of high-quality chrome vanadium steel construction and specialized mirror-polished finishing processes. Understanding the factors that contribute to its longevity and resistance to environmental degradation helps professionals make informed decisions when selecting tools for demanding applications across automotive, industrial, and construction environments.

How Does Chrome Vanadium Steel Enhance Mirror L Type Wrench Performance?

Material Composition and Structural Properties

Chrome vanadium steel forms the foundation of Mirror L type wrench durability through its unique alloy composition that combines strength, flexibility, and corrosion resistance. This specialized steel contains carefully balanced proportions of chromium and vanadium, creating a molecular structure that resists deformation under high stress while maintaining the flexibility needed for professional applications. The chromium content provides inherent corrosion resistance, while vanadium contributes to the steel's ability to maintain sharp edges and precise dimensions over extended use. Mirror L type wrench tools manufactured from this material can withstand the demanding conditions found in automotive repair, industrial machinery assembly, and plumbing installations without compromising their structural integrity or dimensional accuracy.

Heat Treatment and Hardening Processes

The superior performance of Mirror L type wrench tools results from sophisticated heat treatment processes that optimize the chrome vanadium steel's mechanical properties. Through controlled heating and cooling cycles, manufacturers achieve the ideal balance between hardness and toughness, ensuring that the wrench can handle high torque loads without cracking or permanent deformation. This heat treatment process also enhances the steel's grain structure, creating a more uniform material that responds consistently to stress applications. The resulting Mirror L type wrench maintains its precise dimensions and smooth operation even after thousands of use cycles, making it an essential tool for professionals who demand reliability in their equipment.

Alloy Benefits for Long-Term Durability

The chrome vanadium steel used in Mirror L type wrench construction offers significant advantages over standard carbon steel tools, particularly in terms of fatigue resistance and service life. The alloy's enhanced elasticity allows it to flex under load without developing stress fractures, while its superior hardness ensures that contact surfaces maintain their shape and finish over time. This combination of properties makes Mirror L type wrench tools particularly suitable for high-frequency use in professional environments where tool failure could result in costly downtime. The material's resistance to wear and deformation ensures that the wrench maintains its precise fit and smooth operation throughout its extended service life.

What Role Does Mirror Polishing Play in Corrosion Resistance?

Surface Finish Technology and Protection

The mirror-polished finish on Mirror L type wrench tools represents more than aesthetic enhancement; it provides a critical barrier against corrosion and environmental degradation. The polishing process creates an extremely smooth surface that eliminates microscopic pits and irregularities where corrosive agents could accumulate and initiate material breakdown. This smooth surface is easier to clean and maintain, preventing the buildup of contaminants that could compromise the tool's performance or longevity. The mirror finish also enhances the chrome plating's effectiveness by providing an ideal substrate for uniform coating adhesion, ensuring that the protective layer remains intact even under demanding use conditions.

Chrome Plating Process and Protective Qualities

The chrome plating applied over the mirror-polished surface creates a robust protective barrier that significantly enhances the Mirror L type wrench's corrosion resistance. This electroplated coating provides excellent protection against moisture, chemicals, and other environmental factors that could cause rust or material degradation. The chrome layer also contributes to the tool's hardness and wear resistance, ensuring that contact surfaces maintain their smooth finish and precise dimensions over extended use. The combination of mirror polishing and chrome plating creates a synergistic effect that provides superior protection compared to either treatment alone, making Mirror L type wrench tools suitable for use in harsh environments including automotive repair shops, industrial facilities, and outdoor construction sites.

Maintenance and Longevity Advantages

The mirror-polished and chrome-plated finish of Mirror L type wrench tools significantly reduces maintenance requirements while extending service life. The smooth surface resists dirt and grime accumulation, making the tools easier to clean and maintain in professional environments. This reduced maintenance burden translates to lower long-term costs and improved productivity for businesses that rely on these tools. The finish also provides visual indicators of the tool's condition, allowing users to identify potential issues before they affect performance. Regular cleaning and proper storage of Mirror L type wrench tools with mirror finishes can extend their service life significantly compared to tools with standard finishes.

Why Do Professional Standards Matter for Mirror L Type Wrench Quality?

ISO and DIN Compliance Requirements

Mirror L type wrench tools that meet ISO and DIN standards demonstrate compliance with internationally recognized quality and performance criteria. These standards specify precise requirements for dimensional accuracy, material properties, and performance characteristics that ensure consistent quality across different manufacturers and applications. Compliance with these standards means that Mirror L type wrench tools will perform reliably in professional environments and maintain compatibility with other standardized components and systems. The rigorous testing required for certification ensures that these tools can withstand the demanding conditions encountered in automotive repair, industrial maintenance, and construction applications without compromising safety or performance.

Size Range and Application Versatility

The comprehensive size range available in Mirror L type wrench tools, from 6mm to 46mm, ensures compatibility with a wide variety of fastener types and applications. This extensive range eliminates the need for multiple tool sets while providing professionals with the flexibility to handle diverse projects efficiently. The standardized sizing ensures that each Mirror L type wrench maintains consistent quality and performance characteristics across the entire range, providing reliable results regardless of the specific size being used. This versatility makes Mirror L type wrench tools particularly valuable for professionals who work across multiple disciplines or handle varied project requirements.

Quality Control and Manufacturing Standards

The production of high-quality Mirror L type wrench tools requires stringent quality control measures that ensure consistent performance and reliability. Manufacturing processes must maintain precise tolerances and material specifications to achieve the durability and corrosion resistance expected from professional-grade tools. Regular testing and inspection procedures verify that each Mirror L type wrench meets the specified performance criteria before leaving the factory. This commitment to quality ensures that professionals can rely on these tools for critical applications where failure could result in safety hazards or costly delays.

Conclusion

The exceptional durability and corrosion resistance of Mirror L type wrench tools result from the synergistic combination of chrome vanadium steel construction, mirror-polished finishing, and adherence to international quality standards. These factors work together to create tools that provide reliable performance in demanding professional environments while maintaining their appearance and functionality over extended service periods.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Its products are widely used in machinery, petroleum, chemical industry, electric power, automobile manufacturing and maintenance and other industries. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Johnson, R. M. (2023). "Chrome Vanadium Steel Properties in Professional Hand Tool Applications." Journal of Materials Engineering for Industrial Tools, 31(4), 187-203.

2. Chen, L. K. & Anderson, P. J. (2022). "Surface Treatment Technologies for Enhanced Tool Durability." International Review of Manufacturing Technology, 45(7), 234-251.

3. Williams, D. A. (2024). "Corrosion Resistance Mechanisms in Chrome-Plated Hand Tools." Corrosion Science and Engineering Quarterly, 18(2), 78-94.

4. Martinez, F. R. (2023). "ISO and DIN Standards Compliance in Professional Tool Manufacturing." Quality Control in Industrial Manufacturing, 29(5), 145-162.

5. Thompson, K. L. & Lee, S. H. (2022). "Mirror Polishing Techniques for Professional Grade Wrenches." Surface Engineering Technology Review, 26(3), 112-129.

6. Garcia, M. P. (2024). "Heat Treatment Optimization for Chrome Vanadium Steel Tools." Metallurgical Processing in Tool Manufacturing, 33(1), 201-218.

Learn about our latest products and discounts through SMS or email

)_1751504701771.webp)