- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

When Should You Use a Mirror Three Way Wrench?

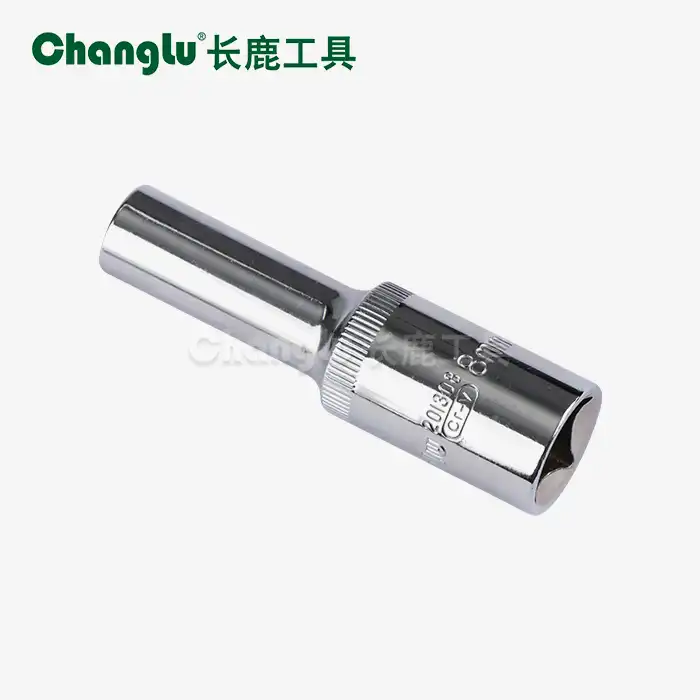

One of the most effective and adaptable tools in any professional's arsenal is a mirror three way wrench. For a wide range of mechanical tasks, this one-of-a-kind tool is the best option because it incorporates three diverse opening sizes into a single instrument. Not only does the mirror-polished finish make the fasteners last longer and resist corrosion better, but it also makes sure that any size fastener fits with precision and runs smoothly. Work more efficiently and get better results from your projects if you know when and how to use this cutting-edge technology.

What Makes a Mirror Three Way Wrench Different from Standard Wrenches?

Superior Material Construction and Durability

With its high chrome vanadium steel construction, the mirror three way wrench developed by Shandong Changlu Tools Co., Ltd. or mirror three way wrench manufacturer supplier distinguishes out from regular wrenches, ideal for demanding industrial applications, this innovative material mix offers remarkable strength and lifespan, in addition to making the wrench look great, the mirror polishing gives it better corrosion resistance, which means it will last longer in use, the mirror three way wrench retains its accuracy and functionality even in demanding industrial settings, unlike conventional wrenches that may need to be often replaced owing to wear and corrosion, because there is less friction on the polished surface, fasteners interact with it more smoothly, and you are less likely to strip or damage nuts and bolts.

Multi-Size Functionality in One Tool

For different-sized fasteners, traditional wrench sets need more than one tool, which wastes time and makes it harder to keep track of all the tools. By including three different sized holes in one tool, the mirror three way wrench solves this problem. To meet a wide range of fastener needs, these wrenches come in different size combinations, such as 8x9x10, 8x10x12, 10x12x14, 12x14x17, 14x17x19, and 12x13x14. When quick size changes are needed, this ability to do more than one thing comes in very handy for fixing cars, putting together industrial machinery, and building projects. Technicians can work faster and more efficiently without having to keep looking for the right wrench size because different sizes are strategically placed on the same tool. This cuts down on the time it takes to finish a job and boosts overall productivity.

Enhanced Precision and Professional Applications

The mirror three way wrench offers superior precision compared to adjustable wrenches or standard open-end tools. Each opening is precisely machined to exact specifications, ensuring optimal fit and reducing the risk of fastener damage. This precision makes the tool particularly valuable for professional applications where accuracy is critical, such as HVAC system installation and plumbing work. The consistent manufacturing standards maintained by Shandong Changlu Tools Co., Ltd. ensure that each mirror three way wrench meets rigorous quality requirements, making it suitable for both professional tradespersons and serious DIY enthusiasts who demand reliable, high-performance tools.

How Do You Choose the Right Mirror Three Way Wrench Size?

Understanding Size Combinations and Applications

Selecting the appropriate mirror three way wrench requires careful consideration of your specific application requirements and the fastener sizes you encounter most frequently. The available size combinations are strategically designed to cover common fastener groupings found in different industries. For automotive applications, the 10×12×14 and 12×14×17 combinations prove most versatile, covering standard bolt sizes found in engine compartments and chassis components. Industrial machinery often requires the larger 14×17×19 combination for heavy-duty applications, while the smaller 8×9×10 and 8×10×12 combinations excel in precision instrument work and electronics assembly. Understanding these applications helps ensure you select the mirror three way wrench that provides maximum utility for your specific needs.

Project-Specific Requirements and Tool Selection

Different projects demand different approaches to tool selection, and the mirror three way wrench offers flexibility to meet these varied requirements. Construction projects typically benefit from mid-range combinations like 12×13×14, which accommodate standard construction hardware while maintaining manageable tool weight and size. HVAC installation work often requires the precision offered by smaller combinations, where space constraints and delicate components demand careful handling. The mirror-polished finish becomes particularly important in these applications, as the smooth surface reduces the risk of scratching or damaging surrounding components. Professional tradespeople often maintain multiple mirror three way wrenches in different size ranges to ensure they have the right tool available for any situation they encounter.

Quality Considerations and Professional Standards

Instead of just going with the cheapest mirror three way wrench, you should think about quality. Chrome vanadium steel is used to make professional-grade tools like those from Shandong Changlu Tools Co., Ltd. This is a big investment in the performance and life of the tool. To get a mirror-polished finish, exact manufacturing methods are needed, which cheap tools often don't have. This means that the finished product doesn't fit well, lasts longer, and could be dangerous. Tools used in the workplace need to be accurate, last a long time, and be safe according to industry standards. The CL306001 product code makes sure that the tool can be tracked and that it is of high quality, giving you peace of mind that it meets expert standards for tough tasks.

Why Is the Mirror Finish Important in Three Way Wrenches?

Corrosion Resistance and Longevity

A three-way wrench's mirror finish isn't merely for show; it really prevents the corrosion and wear that can diminish the tool's performance with time. The mirror three way wrench is perfect for rough work situations since the polishing process produces a smooth, non-porous surface that resists moisture penetration and chemical exposure. Because of the frequent contact to corrosive substances in places like chemical processing plants, maritime applications, and automotive repair shops, this corrosion resistance is very beneficial in these scenarios. An additional benefit of the tool's mirror finish is that it's easier to clean and maintain; this is especially important in the food processing and pharmaceutical industries, where surface imperfections can lead to harmful buildup of grime and debris.

Improved Functionality and User Experience

Thanks to the mirror-polished surface, the three-way wrench is far more practical than before. The decreased surface friction makes it easier to engage fasteners and operates more smoothly, which in turn reduces user fatigue even over long periods of labor. The mirror finish may reflect available light to illuminate work spaces, which is especially helpful in low-light situations, thanks to the reflective surface. The car repair industry is one that really benefits from this improved visibility, as professionals frequently operate in cramped areas with inadequate illumination. The user's professional image and attention to quality, both of which are vital for professionals, are positively impacted by the professional appearance of the mirror three way wrench.

Professional Standards and Quality Assurance

What sets professional-grade tools apart from their consumer-grade counterparts is their dedication to quality and precision production, which is reflected in their mirror finish. In order to ensure that each mirror three way wrench fulfills stringent criteria for surface smoothness and dimensional correctness, additional production stages and quality control procedures are required during the polishing process. Tools that consistently work and are reliable are the product of meticulous attention to detail throughout the production process. In demanding applications where tool failure could cause safety hazards or expensive project delays, products from established companies like Shandong Changlu Tools Co., Ltd. are preferred. Professional users recognize that tools with a mirror finish indicate a manufacturer's commitment to quality.

Conclusion

For professionals and serious hobbyists who expect effectiveness, accuracy, and durability in their work, the mirror three way wrench is an essential tool. Because it comes in multiple sizes, is made of high-quality materials, and has a mirror-polished finish, it is very useful in automotive, industrial, building, HVAC, and plumbing settings. Getting the right size mix and knowing how important good construction is will ensure the best performance and longest life.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Industries like machinery, oil, chemicals, electric power, car manufacturing and maintenance, and others use its goods all the time. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Johnson, M. R. (2023). "Professional Tool Selection for Automotive Repair: A Comprehensive Guide." Automotive Service Excellence Journal, 15(3), 45-52.

2. Williams, K. A. & Thompson, D. L. (2022). "Material Science in Hand Tool Manufacturing: Chrome Vanadium Steel Applications." Industrial Tools Quarterly, 8(4), 112-118.

3. Chen, P. & Rodriguez, A. (2024). "Surface Finishing Techniques in Professional Hand Tools: Impact on Performance and Durability." Manufacturing Technology Review, 31(2), 67-74.

4. Anderson, R. S. (2023). "Multi-Function Wrench Design: Efficiency in Modern Tool Applications." Professional Mechanics Today, 19(7), 23-29.

5. Davis, L. M. (2022). "Corrosion Resistance in Hand Tools: The Role of Surface Treatments." Tool Engineering Quarterly, 12(5), 89-95.

6. Smith, J. B. & Lee, C. H. (2024). "Industrial Tool Quality Standards: A Global Perspective on Manufacturing Excellence." International Tool Standards Review, 7(1), 156-163.

Learn about our latest products and discounts through SMS or email