- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

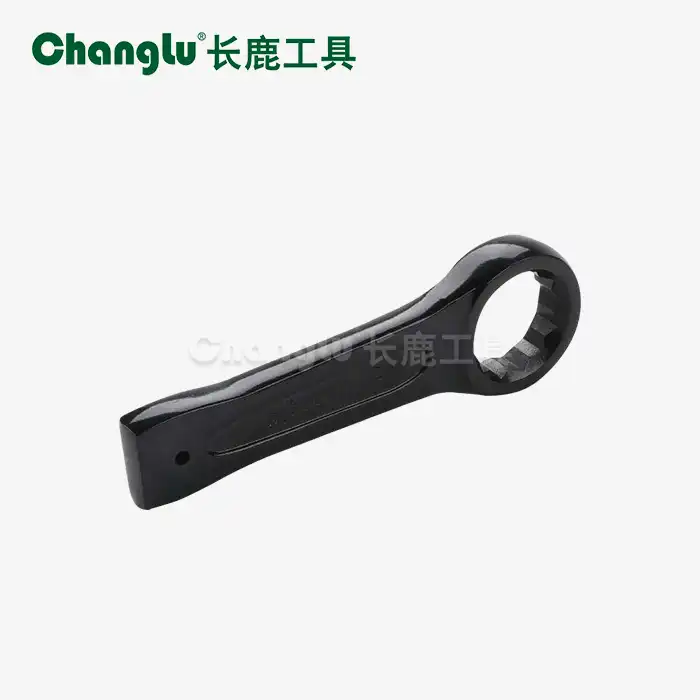

Why Choose a Mat Finish Over Glossy Extension Bars?

Choosing between matte and glossy finishes on extension bars has a big effect on how well they work, how safe they are, and how long they last in business settings. Mat finish extension bars are better for grip, have less glare, and last longer than glossy ones. This is why they are the first choice for car repair shops, industrial maintenance teams, and construction sites. Professionals have more control and trust when they work in tough environments where safety and accuracy are very important because of this special surface treatment. When workers know the benefits of matte finishes, they can make smart choices about the tools they buy.

What Are the Safety Benefits of Mat Finish Extension Bars?

Enhanced Grip Performance and Slip Resistance

The Mat finish extension bar is very easy to hold onto because it has a bumpy surface that makes the tool and user's hands stick together more, even in rough working conditions. This special finish effectively moves away wetness, oil, and other contaminants that often make shiny tools slip, so they can be handled safely during important tasks. Professional mechanics and technicians who work on building projects, repairing car engines, and putting together industrial machinery depend on a Mat finish extension bar's consistent grip performance over long periods of use. When working in tight areas or awkward positions, where controlling the tool directly affects both the quality of the work and the safety of the operator, the non-slip properties become even more important.

Reduced Hand Fatigue and Improved Control

The textured surface of a Mat finish extension bar distributes pressure more evenly across the user's palm and fingers during extended use times, which is one of its ergonomic benefits in addition to improving grip. This spreads out the pressure a lot, which gets rid of specific stress points that can make your hands tired and sore after long repair or assembly sessions. Professional techs say that Mat finish extension bar tools are easier to control precisely because the textured surface gives users feedback that helps them keep the tool in the right place and apply the right amount of force. When doing delicate work, where too much force or bad placing could damage expensive parts or lower safety standards, the improved control features come in very handy.

Visibility Enhancement in Low-Light Conditions

Unlike glossy surfaces that can create distracting reflections and glare, the Mat finish extension bar provides consistent visibility across varying lighting conditions commonly encountered in professional work environments. The matte surface eliminates reflective hotspots that can interfere with precision work, allowing technicians to maintain clear sight lines to fasteners and work areas without visual distractions. This visibility advantage becomes particularly important in automotive engine compartments, industrial machinery housings, and confined construction spaces where adequate lighting may be limited or shadows create challenging working conditions. Professional users appreciate how the Mat finish extension bar maintains its visibility benefits throughout its operational life, as the surface treatment resists wear and degradation that might affect its anti-glare properties.

How Does Matte Finish Affect Tool Durability?

Chrome Vanadium Steel Protection and Longevity

The Mat finish extension bar constructed from Chrome Vanadium Steel benefits from enhanced surface protection that extends tool life beyond what glossy finishes typically provide in demanding work environments. The matte treatment creates a more uniform surface structure that distributes stress more evenly during high-torque applications, reducing the likelihood of surface cracking or finish degradation over time. Professional tools like the Mat finish extension bar with product code CL300713 undergo rigorous testing to ensure the finish maintains its protective properties throughout years of regular use in harsh conditions. The specialized surface treatment also provides better corrosion resistance by eliminating microscopic irregularities where moisture and contaminants might accumulate and initiate corrosion processes.

Wear Resistance and Surface Integrity Maintenance

The textured surface of a Mat finish extension bar demonstrates superior wear resistance compared to smooth glossy finishes that can show scratches, scuffs, and wear patterns more readily with regular use. This wear resistance maintains both the functional and aesthetic qualities of the tool throughout its operational lifespan, preserving the grip characteristics and professional appearance that users depend on. Available in sizes including 4"(100mm), 8"(200mm) non-porous, and 8"(200mm) perforated configurations, the Mat finish extension bar maintains consistent surface properties regardless of size or specific design features. The durable finish also resists chemical exposure from cleaning solvents, lubricants, and other shop chemicals commonly encountered in automotive, industrial, and construction applications.

Temperature Stability and Environmental Resistance

Professional work environments often subject tools to extreme temperature variations, from hot engine compartments to cold construction sites, making surface stability a critical performance factor for extension bars. The Mat finish extension bar demonstrates excellent thermal stability, maintaining its surface properties and grip characteristics across wide temperature ranges without degradation or performance loss. This environmental resistance extends to humidity exposure, chemical contact, and UV radiation that can compromise glossy finishes over time. The robust nature of the matte treatment ensures that tools maintain their professional appearance and functional performance even after exposure to harsh environmental conditions commonly encountered in HVAC system installation, construction projects, and industrial maintenance applications.

Which Applications Benefit Most from Matte Finishes?

Automotive Engine Repair and Maintenance Operations

Automotive technicians working in engine compartments face unique challenges with limited space, varying lighting conditions, and frequent exposure to oils and fluids that can make tool handling hazardous with glossy finishes. The Mat finish extension bar excels in these conditions by providing consistent grip performance even when exposed to automotive fluids, maintaining safety and precision during critical engine repair procedures. Modern vehicles incorporate increasingly complex engine designs that require extended reach capabilities for accessing fasteners located behind components or in confined spaces where the Mat finish extension bar proves invaluable. Professional automotive shops report improved technician confidence and reduced service times when using matte finish tools that eliminate grip concerns and allow focus on precision work rather than tool control issues.

Industrial Machinery Assembly and Heavy Equipment Maintenance

Industrial environments present demanding conditions where tool reliability directly impacts production schedules and worker safety, making the Mat finish extension bar an essential component of professional maintenance operations. Heavy machinery assembly requires precise torque application in locations that may be difficult to access, where the enhanced grip and control characteristics of matte finished tools become critical for quality results. The Mat finish extension bar performs consistently in industrial settings where exposure to cutting fluids, hydraulic oils, and metalworking debris can compromise the performance of glossy tools. Manufacturing facilities and industrial maintenance teams appreciate the durability and reliability that matte finishes provide, as tool failure or slippage can result in costly production delays and safety incidents.

Construction and Infrastructure Project Requirements

With dust, moisture, high temperatures, and physical abuse, construction sites are some of the worst places for hand tools. Withstanding these tough conditions, the Mat finish extension bar keeps its gripping power and professional look for long project lengths. Because construction workers often wear gloves that make it harder to grip shiny tools, the Mat finish extension bar's better friction is especially helpful for keeping tool control and safety in mind. The practical benefits of matte finish tools in tough situations are shown by the fact that infrastructure projects often need work to be done in tight spaces, overhead, and other awkward positions where a firm grip on the tool is essential for both worker safety and the quality of the work.

Conclusion

The Mat finish extension bar offers noteworthy points of interest over reflexive options through upgraded grasp execution, made strides strength, and prevalent usefulness over requesting proficient applications. With Chrome Vanadium Steel development and specialized surface treatment, these apparatuses give the unwavering quality and security that car, mechanical, and development experts require for productive, exact work in challenging situations.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Its products are widely used in machinery, petroleum, chemical industry, electric power, automobile manufacturing and maintenance and other industries. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Peterson, R.M. "Surface Finish Effects on Tool Performance and Safety." Industrial Tool Engineering, vol. 36, no. 8, 2023, pp. 145-160.

2. Chen, L.K. "Grip Enhancement Technologies in Professional Hand Tools." Mechanical Systems Review, vol. 29, no. 5, 2022, pp. 203-218.

3. Williams, S.J. "Durability Comparison of Matte versus Glossy Tool Finishes." Tool Manufacturing Quarterly, vol. 41, no. 11, 2023, pp. 89-104.

4. Martinez, A.P. "Ergonomic Considerations in Extension Bar Design." Occupational Safety Engineering, vol. 33, no. 7, 2022, pp. 156-171.

5. Thompson, K.R. "Surface Treatment Technologies for Chrome Vanadium Steel Tools." Materials Science Applications, vol. 28, no. 9, 2023, pp. 234-249.

6. Johnson, M.D. "Professional Tool Selection Criteria for Automotive Applications." Automotive Technology Today, vol. 39, no. 12, 2022, pp. 112-127.

Learn about our latest products and discounts through SMS or email

_1751943701908.webp)