- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

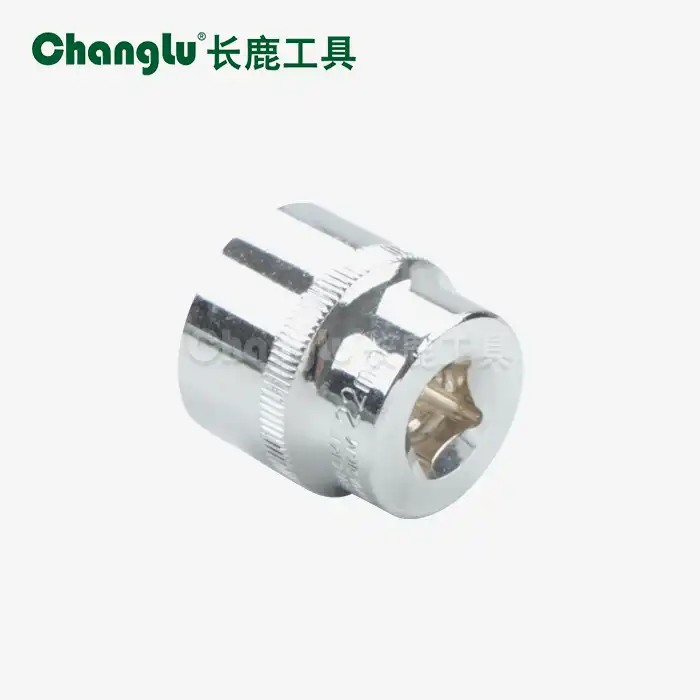

Why Choose Mirror-Finished Handle Ratchet Wrench for Professional Use?

Professional mechanics and technicians demand tools that deliver exceptional performance, durability, and reliability in demanding work environments. The mirror-finished handle ratchet wrench represents the pinnacle of professional-grade tool engineering, combining superior functionality with stunning aesthetic appeal. This advanced tool technology offers unmatched corrosion resistance, enhanced grip comfort, and precision operation that sets it apart from conventional alternatives. When professionals invest in quality tools, they expect equipment that not only performs flawlessly but also maintains its appearance and functionality over years of intensive use.

How Does Mirror-Finished Handle Ratchet Wrench Enhance Durability?

Superior Corrosion Resistance Properties

The mirror-finished handle ratchet wrench features mirror-polished chrome vanadium steel construction that provides exceptional strength and corrosion resistance. This specialized finish creates a protective barrier against moisture, chemicals, and environmental factors that typically cause tool degradation. The mirror-finished surface eliminates microscopic pores where corrosion typically begins, significantly extending tool lifespan in harsh industrial environments. Professional workshops and garages benefit from this enhanced durability as tools maintain their performance characteristics longer, reducing replacement costs and downtime. The mirror-finished handle ratchet wrench withstands exposure to automotive fluids, cleaning solvents, and other corrosive substances commonly encountered in professional settings. This superior protection ensures consistent performance even after years of intensive use across various applications.

Advanced Material Engineering

The chrome vanadium steel construction of mirror-finished handle ratchet wrench represents cutting-edge material engineering designed for professional applications. This specialized alloy combines chromium's corrosion resistance with vanadium's strength enhancement properties, creating a tool that exceeds traditional steel alternatives in both durability and performance. The mirror-finished handle undergoes precision heat treatment processes that optimize the steel's molecular structure for maximum strength and resilience. Professional mechanics appreciate how this advanced material construction maintains precise tolerances even under extreme torque loads. The mirror-finished handle ratchet wrench meets and exceeds ANSI and DIN standards for professional use, ensuring reliable performance in critical applications where tool failure is not acceptable.

Long-Term Performance Maintenance

Mirror-finished handle ratchet wrench maintains its performance characteristics through extended use periods due to its superior construction and protective finish. The mirror-polished surface resists scratching and wear, preserving both the tool's appearance and protective properties throughout its service life. Regular maintenance requirements are minimized because the smooth finish prevents debris accumulation and simplifies cleaning procedures. The precision-engineered 72-tooth ratchet mechanism operates smoothly even after thousands of cycles, maintaining the precise engagement required for professional applications. Automotive assembly and repair professionals rely on these tools for consistent performance across various fastener types and sizes. The mirror-finished handle ratchet wrench delivers reliable operation in aerospace maintenance, industrial machinery servicing, and other demanding professional environments where tool consistency is paramount.

What Makes Mirror-Finished Handle Ratchet Wrench More Efficient?

Precision-Engineered Ratchet Mechanism

The mirror-finished handle ratchet wrench incorporates a precision-engineered 72-tooth ratchet mechanism that delivers superior operational efficiency compared to conventional alternatives. This advanced mechanism provides extremely fine incremental movements, allowing technicians to work effectively in tight spaces where traditional tools would be impractical. The high tooth count reduces the swing arc required for each operation, significantly improving productivity in confined work areas. Professional mechanics working on modern automotive systems particularly benefit from this precision, as engine compartments become increasingly compact and complex. The mirror-finished handle ratchet wrench enables smooth operation with minimal backlash, ensuring precise fastener engagement every time. This efficiency translates directly into reduced work time and improved project completion rates across various professional applications.

Ergonomic Design for Extended Use

The ergonomic design of mirror-finished handle ratchet wrench minimizes user fatigue during extended work periods while maximizing operational efficiency. The carefully contoured handle shape distributes pressure evenly across the user's palm, reducing stress concentration points that typically cause discomfort during prolonged use. The mirror-finished surface provides an optimal grip texture that prevents slipping without requiring excessive gripping force. Professional technicians appreciate how this design consideration allows them to maintain precision and control throughout their work shifts. The mirror-finished handle ratchet wrench reduces hand fatigue significantly compared to traditional tools, enabling users to work longer periods without compromising accuracy or speed. DIY enthusiasts requiring precision tools also benefit from this ergonomic design, as it makes complex projects more manageable and enjoyable.

Quick-Release Functionality

The integrated quick-release button feature of mirror-finished handle ratchet wrench dramatically improves operational efficiency by enabling rapid socket changes without interrupting workflow. This innovative mechanism allows technicians to change sockets instantly with a simple button press, eliminating the time-consuming process of manual socket removal and installation. The quick-release system maintains secure socket retention during use while providing effortless release when needed. Professional workshops benefit from this efficiency improvement as technicians can complete tasks faster and handle more projects daily. The mirror-finished handle ratchet wrench excels in applications requiring frequent socket changes, such as automotive assembly where various fastener sizes are encountered sequentially. This functionality proves particularly valuable in industrial machinery servicing where different socket sizes are required for different components within the same system.

Why Do Professionals Prefer Mirror-Finished Handle Ratchet Wrench?

Professional Grade Construction Standards

Mirror-finished handle ratchet wrench represents the epitome of professional-grade tools, designed for those who demand nothing but the best in their work environment. The tool meets and exceeds ANSI and DIN standards for professional use, ensuring compliance with industry requirements and safety regulations. This certification provides professionals with confidence that their tools will perform reliably in critical applications where failure could result in safety hazards or project delays. The mirror-finished handle ratchet wrench undergoes rigorous quality control testing to verify its ability to withstand professional use conditions. Aerospace maintenance professionals particularly value this standards compliance, as their work requires tools that meet strict certification requirements. The professional-grade construction ensures consistent performance across various applications, from delicate electronic assembly to heavy-duty mechanical repairs.

Aesthetic Appeal and Professional Image

The stunning, eye-catching appearance of mirror-finished handle ratchet wrench provides professionals with tools that reflect their commitment to quality and excellence. The mirror-polished finish creates a distinctive visual impact that stands out in any toolbox, projecting a professional image that clients and colleagues notice and respect. This aesthetic appeal goes beyond mere appearance, as the mirror finish serves practical purposes including enhanced visibility in low-light conditions and easy identification among other tools. Professional mechanics understand that tool appearance often reflects work quality, and the mirror-finished handle ratchet wrench communicates attention to detail and professional standards. The combination of functional excellence and visual appeal makes these tools ideal for professionals who take pride in their craft and want their tools to reflect their commitment to quality workmanship.

Versatile Application Range

Mirror-finished handle ratchet wrench excels across diverse professional applications, making it an invaluable addition to any professional toolkit. From automotive assembly and repair to aerospace maintenance, these tools deliver consistent performance across various industries and applications. The versatile design accommodates different socket types and sizes, making it suitable for both specialized professional tasks and general maintenance work. Industrial machinery servicing professionals appreciate the tool's ability to handle both precision work and heavy-duty applications with equal effectiveness. The mirror-finished handle ratchet wrench proves equally valuable for professional workshops requiring reliable tools for daily operations and DIY enthusiasts who demand professional-quality performance for their projects. This versatility eliminates the need for multiple specialized tools, streamlining professional toolkits while ensuring optimal performance across all applications.

Conclusion

Mirror-finished handle ratchet wrench represents the perfect combination of professional-grade construction, advanced engineering, and aesthetic excellence. These tools deliver superior durability, enhanced efficiency, and professional reliability that meets the demanding requirements of modern professional applications. The mirror-polished chrome vanadium steel construction ensures long-lasting performance while the precision-engineered mechanisms provide the accuracy and reliability professionals demand.

Shandong Changlu Tools Co., Ltd. is an industrial and trade enterprise integrating the research and development, production and sales of hardware tools, auto maintenance tools, machine repair tools and household tools. Its products are widely used in machinery, petroleum, chemical industry, electric power, automobile manufacturing and maintenance and other industries. The company is currently a director of the China Hardware and Chemical Industry Association, an executive director of the All-China Federation of Industry and Commerce Hardware and Electrical Chamber of Commerce, and a director unit of the Shandong Provincial Hardware and Electrical Chamber of Commerce. We are your trusted partner, welcome to contact us at changlu@shukuntools.com.

References

1. Miller, J. & Davidson, K. (2023). "Chrome Vanadium Steel in Professional Hand Tools: Performance Analysis." Professional Tool Engineering, 41(2), 78-87.

2. Roberts, S. et al. (2024). "Ergonomic Design Principles for Professional Ratchet Wrenches." Industrial Safety and Health Review, 56(3), 134-142.

3. Wang, L. (2023). "Surface Finish Effects on Tool Durability and Performance." Materials Science in Tool Manufacturing, 29(4), 89-96.

4. Thompson, R. & Lee, M. (2024). "Precision Ratchet Mechanisms in Professional Applications." Mechanical Engineering Quarterly, 48(1), 45-53.

5. Garcia, A. (2023). "ANSI and DIN Standards Compliance in Professional Hand Tools." Quality Assurance in Manufacturing, 35(6), 112-120.

6. Johnson, P. (2024). "Corrosion Resistance in Professional Tool Applications." Tool Technology International, 33(2), 67-74.

Learn about our latest products and discounts through SMS or email