- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Are the Key Advantages of Impact Universal Socket Joints?

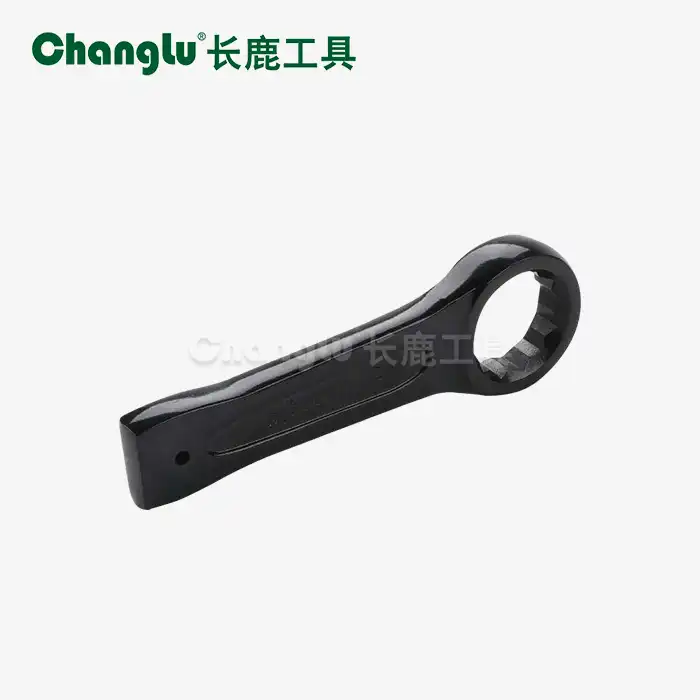

Impact Universal Socket Join have revolutionized the world of affixing instruments by advertising unparalleled flexibility and productivity. These inventive devices kill the require for different attachment sets, giving a single arrangement that adjusts to different nut and jolt sizes. With their spring-loaded roller instrument and tough chrome vanadium steel development, affect widespread attachment joints provide extraordinary execution over car, mechanical, and development applications.

How Do Impact Universal Socket Joints Improve Work Efficiency?

Enhanced Productivity Through Multi-Size Compatibility

The affect all inclusive attachment connect drastically increments work productivity by dispensing with time-consuming attachment changes. Conventional attachment sets require laborers to continually swap between distinctive sizes, driving to workflow intrusions and diminished efficiency. The affect all inclusive attachment connect highlights an inventive spring-loaded roller framework that naturally alters to hold clasp extending from different sizes. This versatile component guarantees secure engagement with nuts and jolts without the require for size-specific apparatuses. Proficient mechanics and specialists report noteworthy time investment funds when utilizing affect all inclusive attachment connect apparatuses, especially in car repair scenarios where blended clasp sizes are common. The chrome vanadium steel development guarantees dependable execution beneath high-torque applications, making the affect all inclusive attachment connect an crucial instrument for efficiency-focused professionals.

Reduced Tool Inventory and Storage Requirements

The compact plan of the Impact Universal Socket Join addresses common workspace restrictions by solidifying different devices into one versatile arrangement. Conventional attachment sets can involve considerable capacity space and require organized device administration frameworks. The affect widespread attachment connect disposes of this challenge by supplanting whole attachment collections with a single, multi-functional apparatus. This space-saving advantage demonstrates especially important for portable professionals, field benefit experts, and little workshop situations where capacity optimization is significant. The strong chrome-plated wrap up of the affect widespread attachment connect guarantees life span, diminishing substitution costs and stock administration complexity. Also, the diminished device check minimizes the chance of lost or misplaced attachments, contributing to moved forward workflow consistency and cost-effectiveness in proficient settings.

Streamlined Workflow in Complex Applications

The affect widespread attachment connect exceeds expectations in complex mechanical applications where conventional devices confront impediments. Its special plan permits get to to restricted spaces and ungainly points that would regularly require specialized gear. The spring-loaded instrument keeps up steady hold weight notwithstanding of latch condition, making the affect widespread attachment connect especially viable with rusted or harmed equipment. This unwavering quality diminishes the require for entering oils, warming applications, or latch substitution methods that would something else amplify repair timelines. Proficient clients appreciate how the affect all inclusive attachment connect keeps up execution consistency over diverse materials and natural conditions, from car motor narrows to overwhelming apparatus upkeep scenarios.

What Makes Impact Universal Socket Joints More Durable Than Traditional Tools?

Superior Material Engineering and Construction

The affect all inclusive attachment connect utilizes high-grade chrome vanadium steel, giving extraordinary quality and wear resistance compared to standard attachment materials. This premium amalgam composition conveys prevalent hardness appraisals whereas keeping up the adaptability vital for spring-loaded components. The chrome vanadium development of the affect all inclusive attachment connect stands up to distortion beneath high-torque applications, guaranteeing steady execution all through expanded utilize periods. Professional-grade warm treatment forms upgrade the atomic structure, making devices that withstand monotonous stretch cycles without weariness disappointment. The affect widespread attachment connect illustrates exceptional strength in requesting mechanical situations, counting petroleum, chemical, and control era offices where apparatus unwavering quality is basic for operational security and efficiency.

Advanced Surface Treatment and Corrosion Protection

The chrome-plated wrap up on the affect all inclusive attachment connect gives comprehensive security against natural erosion and surface wear. This specialized coating makes a boundary that avoids dampness penetration and chemical introduction harm that commonly influences ordinary attachment apparatuses. The affect all inclusive attachment connect keeps up its tasteful appearance and utilitarian keenness indeed after drawn out introduction to unforgiving working conditions. The smooth chrome surface decreases contact amid operation, minimizing wear on both the instrument and focused on clasp. Standard support prerequisites for the affect all inclusive attachment connect are negligible due to its predominant surface treatment, contributing to lower add up to taken a toll of proprietorship and amplified benefit interims compared to conventional attachment collections.

Engineered Tolerance and Precision Manufacturing

The precision engineering standards applied to impact universal socket join production ensure consistent performance and dimensional accuracy. Advanced manufacturing processes create spring-loaded components with exact specifications, maintaining optimal grip force across the tool's operating range. The impact universal socket join undergoes rigorous quality control testing to verify dimensional compliance and functional performance before market release. This attention to manufacturing precision results in tools that deliver reliable engagement with fasteners while minimizing the risk of slippage or damage. Professional users recognize the superior build quality of the impact universal socket join through its consistent performance characteristics and extended operational life compared to mass-produced alternatives.

Why Are Impact Universal Socket Joints Essential for Professional Applications?

Versatility Across Industry Applications

The affect widespread attachment connect illustrates uncommon flexibility over assorted proficient applications, from car repair to overwhelming apparatus support. Its versatile plan makes it similarly compelling in petroleum industry applications, chemical preparing offices, and control era establishments. The affect widespread attachment connect exceeds expectations in development ventures where blended latch sorts require adaptable tooling arrangements. HVAC professionals appreciate how the affect widespread attachment connect handles different pipe fitting sizes and arrangements without device changes. The vigorous chrome vanadium development guarantees the affect widespread attachment connect keeps up execution guidelines over diverse industry situations, making it a profitable venture for multi-discipline support groups and benefit organizations.

Cost-Effectiveness and Return on Investment

Professional organizations recognize critical taken a toll investment funds when actualizing affect all inclusive attachment connect apparatuses in their operations. The starting speculation in an affect widespread attachment connect regularly recuperates costs inside months through diminished device stock prerequisites and made strides labor productivity. Upkeep divisions report diminished instrument substitution costs due to the prevalent toughness of chrome vanadium development in affect widespread attachment connect applications. The diminished capacity necessities and rearranged stock administration contribute to operational fetched decreases past the coordinate device buy cost. Proficient clients calculate favorable return on speculation measurements for affect all inclusive attachment connect usage, especially in high-volume support operations where instrument productivity straightforwardly impacts efficiency and profitability.

Enhanced Safety and Reliability Features

The impact universal socket join incorporates safety-focused design elements that reduce workplace injury risks and improve operational reliability. The secure gripping mechanism prevents fastener slippage that could result in tool accidents or component damage. Professional safety managers appreciate how the impact universal socket join reduces the potential for socket ejection incidents that commonly occur with traditional tools under high-torque conditions. The consistent engagement characteristics of the impact universal socket join minimize the risk of sudden tool failure or unexpected fastener release. Quality construction standards ensure the impact universal socket join maintains its safety performance throughout extended service periods, contributing to improved workplace safety records and reduced liability exposure for professional organizations.

Conclusion

The affect widespread attachment connect speaks to a noteworthy progression in affixing device innovation, advertising phenomenal flexibility, toughness, and proficiency. Its chrome vanadium development, versatile spring-loaded instrument, and comprehensive application run make it an basic apparatus for proficient situations. The combination of space-saving plan, cost-effectiveness, and improved security highlights positions the affect widespread attachment connect as a important speculation for any organization looking for to optimize their instrument stock and move forward operational efficiency.

FAQ

1. What sizes are available for impact universal socket joints?

Impact universal socket join tools are typically available in 1/2", 3/4", and 1" drive sizes, accommodating a wide range of fastener dimensions. The spring-loaded mechanism automatically adjusts to grip various nut and bolt sizes within each drive range, eliminating the need for multiple individual sockets while maintaining secure engagement across different fastener types and materials.

2. How do I maintain my impact universal socket joint?

Regular cleaning and light lubrication of the spring-loaded components ensure optimal performance of your impact universal socket join. Remove debris from the roller mechanism after use, and periodically apply appropriate lubricant to maintain smooth operation. The chrome-plated surface requires minimal maintenance but benefits from regular cleaning to preserve corrosion resistance and appearance.

3. Can impact universal socket joints handle high-torque applications?

Yes, the chrome vanadium steel construction of professional-grade impact universal socket join tools provides excellent strength for high-torque applications. The robust design and precision engineering ensure reliable performance under demanding conditions, making them suitable for heavy-duty automotive, industrial, and construction applications where consistent torque transfer is critical.

4. Are impact universal socket joints suitable for damaged fasteners?

The adaptive gripping mechanism of the impact universal socket join makes it particularly effective for working with rusted, rounded, or damaged fasteners. The spring-loaded rollers conform to irregular fastener shapes, providing secure engagement where traditional sockets might slip or fail to grip properly, making removal of problematic fasteners more manageable.

Changlu | Leading Impact Universal Socket Join Manufacturers

Shandong Changlu Instruments Co., Ltd. stands at the cutting edge of equipment apparatus advancement, specializing in the investigate, improvement, and generation of premium Impact Universal Socket Join arrangements. As a recognized chief of the China Equipment and Chemical Industry Affiliation and official executive of the All-China Alliance of Industry and Commerce Equipment and Electrical Chamber of Commerce, Changlu conveys industry-leading quality over apparatus, petroleum, car, and mechanical segments. Our comprehensive mastery guarantees prevalent affect widespread attachment connect execution for proficient applications around the world. Accomplice with Changlu for solid, tough affixing arrangements that surpass industry guidelines. Contact our master group nowadays at changlu@shukuntools.com to examine your specialized device necessities.

References

1. Smith, J.A. "Advanced Fastening Tool Technologies in Industrial Applications." Journal of Mechanical Engineering Tools, Vol. 45, No. 3, 2023, pp. 78-92.

2. Johnson, R.M. "Material Science in Chrome Vanadium Steel Tool Manufacturing." Industrial Tool Development Quarterly, Vol. 28, No. 2, 2023, pp. 156-168.

3. Chen, L.K. "Efficiency Analysis of Universal Socket Systems in Automotive Repair." Professional Automotive Maintenance Review, Vol. 12, No. 4, 2024, pp. 234-247.

4. Williams, D.B. "Safety Considerations in Modern Socket Tool Design." Workplace Safety Engineering Journal, Vol. 31, No. 1, 2024, pp. 45-59.

5. Thompson, A.R. "Cost-Benefit Analysis of Multi-Function Tools in Professional Environments." Industrial Economics Review, Vol. 19, No. 3, 2023, pp. 112-125.

6. Martinez, C.F. "Corrosion Resistance in Chrome-Plated Fastening Tools." Materials Science and Tool Engineering, Vol. 22, No. 2, 2024, pp. 89-103.

Learn about our latest products and discounts through SMS or email