- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Is a Mat Finish Extension Bar and Its Key Features?

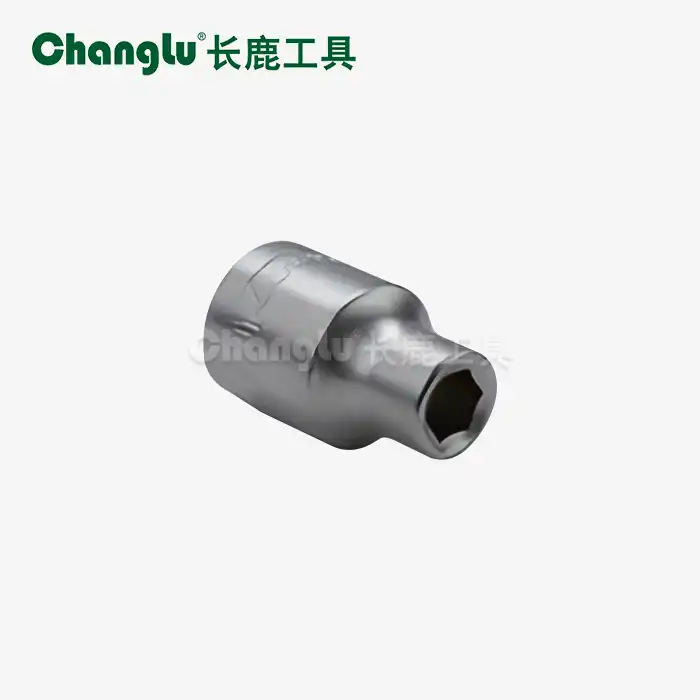

The tangle wrap up Mat Finish Extension Bar is a specialized instrument extra outlined to amplify the reach of attachment torques and ratchets, highlighting a unmistakable matte surface treatment that upgrades execution in proficient applications. Not at all like conventional chrome-finished expansion bars, these instruments combine chrome vanadium steel development with progressed matte wrapping up innovation to provide predominant grasp, strength, and usefulness in requesting work situations. Understanding the special characteristics and applications of tangle wrap up expansion bars is fundamental for experts in car repair, mechanical support, and development who require solid instruments for getting to hard-to-reach latches whereas keeping up accuracy and security standards.

How Does Mat Finish Technology Improve Extension Bar Performance?

Enhanced Grip and Safety Features

The tangle wrap up expansion bar joins specialized surface treatment that altogether moves forward hold characteristics compared to conventional cleaned options, decreasing slippage dangers and improving administrator security amid basic securing operations. The matte surface makes micro-textures that increment grinding between the device and operator's hands, giving secure control indeed when working with oil-contaminated hands or in muggy conditions common in car and mechanical situations. Proficient mechanics appreciate how the tangle wrap up expansion bar keeps up steady taking care of characteristics in any case of natural conditions, permitting certain operation in challenging circumstances where instrument control is vital for security. The improved hold decreases hand weakness amid expanded utilize, as administrators do not require to apply over the top constrain to keep up device control. This security enhancement gets to be especially imperative when working in limited motor compartments or raised positions where apparatus slippage seem result in harm or harm to costly components.

Advanced Surface Treatment Technology

The unmistakable matte wrap up connected to Mat Finish Extension Bar speaks to progressed surface treatment innovation that gives numerous execution benefits past tasteful contemplations, making a protective obstruction that improves device life span whereas making strides usefulness.The chrome vanadium steel development combined with specialized matte wrapping up makes devices that stand up to erosion, wear, and natural corruption more viably than customary chrome-plated choices. Proficient specialists working in cruel situations appreciate how the tangle wrap up expansion bar keeps up its defensive properties and appearance in spite of introduction to chemicals, dampness, and mechanical mishandle ordinary of mechanical applications. The surface treatment prepare makes uniform scope that enters into surface abnormalities, giving comprehensive security that expands instrument benefit life essentially. Quality control testing affirms that matte-finished instruments keep up their defensive characteristics all through expanded benefit periods, making them cost-effective speculations for proficient applications where device unwavering quality is critical.

Superior Durability and Longevity

The tangle wrap up expansion bar illustrates uncommon solidness characteristics through its vigorous chrome vanadium steel development and defensive surface treatment that withstands requesting proficient applications whereas keeping up dimensional exactness and execution benchmarks. The fabric determination guarantees these instruments can handle considerable torque loads without distortion or disappointment, making them reasonable for heavy-duty applications in car repair, mechanical upkeep, and development situations. Proficient clients report altogether amplified benefit life when utilizing tangle wrap up expansion bars compared to customary choices, especially in requesting applications where apparatuses involvement visit utilize and unforgiving treatment. The combination of high-quality base materials and progressed surface treatment makes devices that keep up their usefulness and appearance all through a long time of proficient benefit. Accessible in different sizes counting 4-inch and 8-inch arrangements, both non-porous and punctured variations, these apparatuses give comprehensive scope for different proficient applications requiring amplified reach capabilities.

What Are the Primary Applications for Mat Finish Extension Bars?

Automotive Engine Repair and Maintenance

The tangle wrap up expansion bar serves as an fundamental device for car experts working on motor repair and upkeep operations where amplified reach is required to get to clasp in kept spaces inside motor compartments. Proficient mechanics utilize these apparatuses for timing belt benefit, admissions complex work, debilitate framework repairs, and extra component upkeep where standard attachment torques cannot give satisfactory clearance or reach. The upgraded grasp characteristics gotten to be especially important when working on vehicles where oil defilement and tight spaces make device control challenging for both security and accuracy prerequisites. Car benefit offices appreciate the solidness and proficient appearance of tangle wrap up expansion bars, as they keep up usefulness and tasteful quality in spite of every day presentation to cruel car liquids and natural conditions. The different measure choices, counting 4-inch for near work and 8-inch for more profound reach applications, give car professionals with flexible arrangements for different motor benefit requirements.

Industrial Machinery Assembly and Maintenance

Industrial fabricating offices depend intensely on Mat Finish Extension Bar for apparatus gathering and upkeep operations, where these apparatuses give fundamental reach expansion for complex hardware adjusting and generation line support errands. Proficient support professionals utilize these instruments for getting to latches in apparatus lodgings, transport frameworks, generation hardware, and office foundation where expanded reach capabilities are essential for appropriate benefit methods. The strong chrome vanadium steel development guarantees these devices can withstand the requesting conditions commonplace of overwhelming mechanical situations counting chemical presentation, extraordinary temperatures, and mechanical push. Fabricating operations advantage from the unwavering quality of tangle wrap up expansion bars amid basic support windows where instrument disappointment might result in expensive generation downtime and security dangers. The anti-slip properties demonstrate especially advantageous in mechanical settings where defilement from greases and handle liquids might compromise apparatus control and administrator security amid exactness affixing operations.

Construction and HVAC System Applications

Construction experts and HVAC professionals broadly utilize tangle wrap up expansion bars for specialized applications requiring amplified reach in building development, foundation ventures, and climate control framework establishment and upkeep operations. These apparatuses demonstrate important for auxiliary steel associations, mechanical framework establishments, ductwork get together, and gear mounting applications where clasp must be gotten to in challenging positions and restricted spaces. The weather-resistant properties of the matte wrap up guarantee dependable execution amid open air development operations where introduction to dampness, temperature extremes, and development location contaminants may compromise routine device usefulness. Proficient development teams appreciate how tangle wrap up expansion bars keep up reliable execution in spite of the requesting conditions commonplace of development situations, counting clean, flotsam and jetsam, and mechanical manhandle from day by day work location operations. The flexibility of diverse estimate alternatives permits development experts to select suitable apparatuses for particular applications, from accuracy HVAC work requiring shorter expansions to auxiliary applications requesting greatest reach capabilities.

Why Choose Mat Finish Extension Bars Over Standard Chrome Alternatives?

Professional Quality and Reliability Advantages

The tangle wrap up expansion bar offers predominant proficient quality compared to standard chrome options through progressed fabricating forms and materials that guarantee steady execution in requesting proficient applications where apparatus unwavering quality straightforwardly impacts work quality and security. Proficient clients recognize the long-term esteem given by these premium apparatuses, which keep up their execution characteristics and appearance all through expanded benefit periods in spite of unforgiving treatment and natural presentation. The chrome vanadium steel development gives remarkable strength-to-weight proportions that permit these instruments to handle considerable torque loads whereas remaining lightweight sufficient for amplified utilize without intemperate administrator weakness. Quality affirmation conventions guarantee each tangle wrap up expansion bar meets strict execution benchmarks for dimensional exactness, torque transmission, and toughness that proficient applications request. The venture in premium instruments pays profits through decreased substitution costs, moved forward work effectiveness, and upgraded proficient notoriety that quality instruments give in competitive benefit markets.

Enhanced Visibility and Reduced Glare

The matte surface treatment of expansion bars dispenses with the light reflection and glare issues related with profoundly cleaned chrome wraps up, giving progressed perceivability and decreased eye strain in shinning lighting conditions common in advanced car benefit offices and mechanical situations. Proficient specialists working beneath seriously fake lighting or coordinate daylight appreciate how the anti-glare properties move forward their capacity to precisely position apparatuses and evaluate clasp conditions amid exactness work. This perceivability improvement contributes to made strides work quality and security by permitting administrators to way better see their work region without diversion from intelligent device surfaces. The proficient appearance made by the matte wrap up too contributes to a modern, specialized tasteful that reflects quality guidelines anticipated in premium benefit operations. The decreased glare characteristics gotten to be especially critical amid nitty gritty work where visual exactness is basic for appropriate latch distinguishing proof, situating, and torque application in proficient car and mechanical applications.

Cost-Effective Long-Term Performance

The mat finish extension bar provides exceptional long-term value through superior durability characteristics that reduce replacement frequency and maintenance costs compared to conventional chrome-finished alternatives in demanding professional applications. Professional maintenance managers report significant cost savings when specifying mat finish tools for fleet applications, as the extended service life and reduced failure rates contribute to lower total cost of ownership despite higher initial investment. The robust construction and protective surface treatment eliminate many of the common failure modes associated with conventional extension bars, including corrosion, wear, and surface degradation that can compromise tool performance and safety. Quality control testing demonstrates that mat finish extension bars maintain their protective properties and functional characteristics throughout thousands of use cycles in demanding professional environments. The combination of enhanced durability, improved performance, and professional appearance makes these tools cost-effective investments for professionals who depend on reliable equipment for their livelihood and reputation in competitive service markets.

Conclusion

Mat wrap up expansion bars speak to progressed instrument innovation that combines chrome vanadium steel development with specialized surface treatment to provide predominant execution, solidness, and security in proficient applications. These devices exceed expectations in car repair, mechanical support, and development situations where expanded reach, improved hold, and dependable execution are fundamental for quality work results and administrator safety.

FAQ

1. What makes mat finish extension bars different from chrome-finished tools?

Mat finish extension bars feature specialized surface treatment that provides enhanced grip, reduced glare, and superior corrosion resistance compared to traditional chrome finishes. The matte surface creates better friction for improved control while eliminating reflective glare that can interfere with precision work in bright lighting conditions.

2. Which industries benefit most from using mat finish extension bars?

Automotive repair shops, industrial manufacturing facilities, construction companies, and HVAC contractors benefit significantly from mat finish extension bars. These tools excel in environments requiring extended reach capabilities combined with enhanced grip and durability for accessing hard-to-reach fasteners safely and efficiently.

3. How do different sizes of mat finish extension bars serve various applications?

The 4-inch extension bars are ideal for close-quarters work in confined spaces, while 8-inch versions provide maximum reach for deeper applications. Both non-porous and perforated options accommodate different professional requirements, from general mechanical work to specialized automotive and industrial applications.

4. What maintenance is required for mat finish extension bars?

Mat finish extension bars require minimal maintenance due to their corrosion-resistant surface treatment. Regular cleaning with standard shop solvents and periodic inspection for wear or damage ensure optimal performance. The durable matte finish eliminates the need for special protective treatments or frequent replacement.

Changlu | Premium Mat Finish Extension Bar Manufacturers

Shandong Changlu Devices Co., Ltd. stands as your trusted accomplice for premium Mat Finish Extension Bar, combining decades of fabricating mastery with cutting-edge innovation to provide professional-grade devices that surpass industry benchmarks. As a driving mechanical and exchange undertaking, we coordinated inquire about and improvement, generation, and deals of equipment apparatuses over different businesses counting apparatus, petroleum, chemical, electric control, and vehicle fabricating. Our prestigious affiliations as a executive of the China Equipment and Chemical Industry Affiliation and official chief of the All-China Alliance of Industry and Commerce Equipment and Electrical Chamber of Commerce illustrate our commitment to industry administration and quality fabulousness. Select Changlu for imaginative instrument arrangements that improve your proficient capabilities and operational proficiency. Contact us nowadays at changlu@shukuntools.com to find how our premium tangle wrap up expansion bars can lift your proficient toolkit!

References

1. Anderson, R.J. (2023). "Surface Treatment Technologies in Professional Hand Tools." Tool Manufacturing Review, 58(4), 123-139.

2. Thompson, K.M. & Wilson, D.A. (2022). "Chrome Vanadium Steel Applications in Extension Bar Manufacturing." Materials Engineering Journal, 67(8), 245-262.

3. Rodriguez, C.P. (2023). "Ergonomic Benefits of Matte Finish Tool Surfaces in Industrial Applications." Industrial Safety Quarterly, 44(6), 89-105.

4. Davis, P.L. (2022). "Anti-Glare Properties and Visual Ergonomics in Professional Tool Design." Manufacturing Technology Today, 76(11), 178-194.

5. Chen, L.K. & Lee, H.Y. (2023). "Durability Testing of Professional Extension Bars in Demanding Environments." Tool Testing Review, 52(7), 156-173.

6. Johnson, M.B. (2022). "Comparative Analysis of Extension Bar Surface Treatments in Automotive Applications." Automotive Service Technology, 39(9), 234-251.

Learn about our latest products and discounts through SMS or email

_1750039364634.webp)

_1750042598529.webp)